Efekti korozije na integritet konstrukcije i životni vek cevi za bušenje izvora nafte Naučni rad

Glavni sadržaj članka

Apstrakt

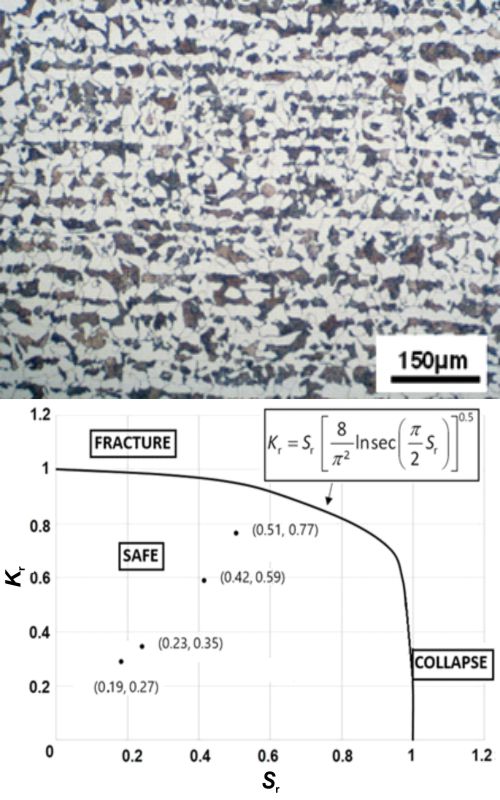

Uticaj korozije na integritet i vek naftnih bušećih cevi je analiziran eksperimentalnim, analitičkim i numeričkim metodama. Eksperimenti su rađeni na standardnim zateznim i “CT” epruvetama, ispitinim statičkim opterećenjem, Šarpi epruvetama ispitanim na udarno opterećenje i epruvtama na savijanje u 3 tačke, ispitanim na amplitudno opterećenje. U svakom slučaju je ispitan novi i korišćeni materijala da bi se odredio uticaj korozije. Rezultati su ukazali na mali uticaj korozije u slučaju zateznih svojstava i žilavosti, a relativno veliku uticaj u slučaju žilavosti loma I brzine rasta zamorne prsline, što značajno povećava rizik od loma i smanjuje preostali vek cevi. Kvantifikacija ovog uticaja je određena pomoću analitičkih izraza za factor integriteta napona. Nedavno uvedeni pristup analizi rizika je primenjen da se odredio nivo rizika u novim i korićenim cevima, pri proračunskom i ispitnom pritisku.

Detalji članka

Broj časopisa

Rubrika

Ovaj rad je pod Creative Commons Aуторство-Nekomercijalno-Bez prerade 4.0 Internacionalna licenca.

Kada je rukopis prihvaćen za objavlјivanje, autori prenose autorska prava na izdavača. U slučaju da rukopis ne bude prihvaćen za štampu u časopisu, autori zadržavaju sva prava.

Na izdavača se prenose sledeća prava na rukopis, uklјučujući i dodatne materijale, i sve delove, izvode ili elemente rukopisa:

- pravo da reprodukuje i distribuira rukopis u štampanom obliku, uklјučujući i štampanje na zahtev;

- pravo na štampanje probnih primeraka, reprint i specijalnih izdanja rukopisa;

- pravo da rukopis prevede na druge jezike;

- pravo da rukopis reprodukuje koristeći fotomehanička ili slična sredstva, uklјučujući, ali ne ograničavajući se na fotokopiranje, i pravo da distribuira ove kopije;

- pravo da rukopis reprodukuje i distribuira elektronski ili optički koristeći sve nosioce podataka ili medija za pohranjivanje, a naročito u mašinski čitlјivoj/digitalizovanoj formi na nosačima podataka kao što su hard disk, CD-ROM, DVD, Blu-ray Disc (BD), mini disk, trake sa podacima, i pravo da reprodukuje i distribuira rukopis sa tih prenosnika podataka;

- pravo da sačuva rukopis u bazama podataka, uklјučujući i onlajn baze podataka, kao i pravo prenosa rukopisa u svim tehničkim sistemima i režimima;

- pravo da rukopis učini dostupnim javnosti ili zatvorenim grupama korisnika na osnovu pojedinačnih zahteva za upotrebu na monitoru ili drugim čitačima (uklјučujući i čitače elektonskih knjiga), i u štampanoj formi za korisnike, bilo putem interneta, onlajn servisa, ili putem internih ili eksternih mreža.

Kako citirati

Funding data

-

Ministarstvo Prosvete, Nauke i Tehnološkog Razvoja

Grant numbers 451-03-9/2021-14/200105; 451-03-9/2021 -14/200213

Reference

Popoola LT, Grema AS, Latinwo GK, Gutti B, Balogun AS. Corrosion problems during oil and gas production and its mitigation, Int J Ind Chem. 2013; 4(1); 35; http://dx.doi.org/10.1186/2228-5547-4-35

Wasim M, Djukic M. External corrosion of oil and gas pipelines: A review of failure mechanisms, J Nat Gas Sci Eng. 2022; 100: 104467, https://doi.org/10.1016/j.jngse.2022.104467

Perez TE. Corrosion in the oil and gas industry: an increasing challenge for materials, JOM 2013; 65(8): 1033-1042; https://doi.org/10.1007/s11837-013-0812-z

Sharma SK, Maheshwari S. A review on welding of high strength oil and gas pipeline steels. J Nat Gas Sci Eng 2017; 38: 203-217; ISSN: 1875-5100

Askari M, Aliofkhazraei M, Afroukhteh, S. A comprehensive review on internal corrosion and cracking of oil and gas pipelines, J Nat Gas Sci Eng. 2019; 71: 102971; https://doi.org/10.1016/j.jngse.2019.102971

http://earth.uni-muenster.de/earth/d/dokumente/schlumberger/English/Corrosion/, 05.1999

Šarkoćević Ž, Arsić M, Medjo B, Kozak D, Rakin M, Burzić Z, Sedmak A. Damage level estimate of API J55 steel for welded seam casing pipes. Strojarstvo: J Theory Appl Mech Eng 2009; 51: 303-311; https://doi.org/10.1016/j.mspro.2014.06.155

Lazić Vulićević Lj, Arsić M, Šarkoćević Ž, Sedmak A, Rakin M. Structural life assessment of oil rig pipes made of API J55 steel by high frequency welding, Technical gazette 2013; 20(6): 1091-1094; ISSN: 1330-3651

Medjo B, Rakin M, Gubeljak N, Matvienko Y, Arsic M, Sarkocevic Z, Sedmak A. Failure resistance of drilling rig casing pipes with an axial crack, Eng Fail Anal. 2015; 58: 429-440; https://doi.org/10.1016/j.engfailanal.2015.05.015

Rakin M, Medjo B, Arsić M, Šarkoćević Z, Sedmak A. Effect of exploitation conditions and flaw geometry on the load carrying capacity of casing pipes for oil drilling rigs, Key Eng Mat. 2012; 488-489: 577-580; https://doi.org/10.1016/j.mspro.2014.06.155

Azevedo CRF, Sinatora A. Failure analysis of a gas pipelines, Instituto de Pesquisas Tecnologicas do Estado de Sao Paulo, Eng Fail Anal. 2004; 11: 387-400; https://doi.org/10.1016/j.engfailanal.2003.06.004

Assanelli AP, Toscano RG, Johnson DH, Dvorkin EN. Experimental/numerical analysis of the collapse behavior of steel pipes. Eng Computat. 2000; 17: 459 - 86.

Fu B, Batte AD. Advanced Methods for the Assessment of Corrosion in Linepipe, Health and Safety Executive Summary Report, OTO 1999-051, HSE Books, 1999; https://www.hse.gov.uk/research/otopdf/1999/oto99051.pdf

Kiefner J, Vieth PA. Modified criterion for evaluating the strength of corroded pipe, Final Report for PR 3-805 project to the Pipeline Supervisory Committee of the American Gas Association, Battelle, Ohio, 1989.; https://www.worldcat.org/title/final-report-on-project-pr-3-805-a-modified-criterion-for-evaluating-the-remaining-strength-of-corroded-pipe/oclc/43015134

Kiefner J, Vieth P. Evaluating pipe - 1 new method corrects criterion for evaluating corroded pipe, Oil & Gas J. 1990; 6: 56-9

Fu B, Kirkwood M. Predicting failure pressure of internally corroded linepipe using the finite element method, OMAE95, Pipeline Technology, international conference on offshore mechanics & arctic engineering, 1995; V: 175-85.; ISBN 0-7918-1311-8; TRN: IM9615%%245

Lee J-S, Ju J-B, Jang J, Kim W-S, Kwon D. Weld crack assessments in API X65 pipeline: failure assessment diagrams with variations in representative mechanical properties, Mat Sci Eng. 2004; 373: 122-30; https://doi.org/10.1016/j.msea.2003.12.039

Rakin M, Medjo B, Arsić M, Šarkoćevic Ž, Ivanović I, Sedmak A. API J55 steel casing pipe with an initial surface crack under internal pressure - Determination of fracture parameters, Key Eng Mat. 2014; 601: 65-70; 10.4028/www.scientific.net/KEM.488-489.577

Rakin M, Arsić M, Medjo B, Šarkoćević Ž, Sedmak A. Structural integrity assurance of casing pipes in the oil and gas industry, WIT Trans Built Environ. 2013; 134: 401-410; https://doi.org/10.2495/SAFE130361

Kirin S, Sedmak A, Zaidi R, Grbović A, Šarkočević Ž, Comparison of experimental, numerical and analytical risk assessment of oil drilling rig welded pipe based on fracture mechanics parameters, Eng Fail Anal. 2020; 114(4); https://doi.org/10.1016/j.engfailanal.2020.104600

Sedmak A, Arsić M, Šarkoćević Ž, Medjo B, Rakin M, Arsić D, Lazić M. Remaining strength of API J55 steel casing pipes damaged by corrosion, Int J Press Vess Piping. 2020; 188; https://doi.org/10.1016/j.ijpvp.2020.104230

Zaidi R, Kozak D, Sedmak A, Kirin S, Franulovic M. Risk assessment based on analytical evaluation of structural integrity and life of drilling rig pipe, Procedia Struct. Integr. 2021; 33: 1181-1186; https://doi.org/10.1016/j.prostr.2021.10.132

Šarkoćević Ž. Resistance to Damage and Fracture of Protective Welded Pipes in Oil Wells, Ph.D. Dissertation (in Serbian), University of Belgrade, 2010.

Zaidi R. Application of fracture mechanics parameters to residual life assessment of welded pipes exploitation under fatigue loading, Ph.D. Dissertation, University of Belgrade, 2021.

Golubović T, Sedmak A, Spasojević Brkić V, Kirin S, Rakonjac I. Novel risk based assessment of pressure vessels integrity. Technical Gazette 2018; 25: 803-807; https://doi.org/10.17559/tv-20170829144636

Zaidi R, Sedmak A, Kirin S, Martić I, Šarkočević Z. Structural integrity and life assessment of oil drilling rig pipes using analytical method, Struct Integ Life. 2022; 22: 63-68

Sedmak A, Algool M, Kirin S, Rakicevic B, Bakic R. Industrial safety of pressure vessels - Structural integrity point of view, Hem. Ind 2016; 70: 685-694; https://doi.org/10.2298/HEMIND150423005S

Golubović T, Sedmak A, Spasojević Brkić V, Kirin S, Veg E. Welded joints as critical regions in pressure vessels – case study of vinyl-chloride monomer storage tank, Hem Ind. 2018; 72(4): 177-182; https://doi.org/10.2298/HEMIND171009006G

Zaidi R, Sedmak A, Kirin S, Grbovic A, Li W, Lazic Vulicevic L, Sarkocevic Z. Risk assessment of oil drilling rig welded pipe based on structural integrity and life estimation, Eng. Fail Analysis. 2020; 112: 104508; https://doi.org/10.1016/j.engfailanal.2020.104508

ASTM E8/E8M-08, Standard Test Methods for Tension Testing of Metallic Materials

ASTM A370-20, Standard Test Methods and Definitions for Mechanical Testing of Steel Products

ASTM E23-01, Standard Test Methods for Notched Bar Impact Testing of Metallic Materials

ASTM E1820-20, Standard Test Method for Measurement of Fracture Toughness

ASTM E647 - 15e1 Standard Test Method for Measurement of Fatigue Crack Growth Rates

BS 7910:2005 Guide to methods for assessing the acceptability of flaws in metallic structures, vol. 3, 2005

FITNET Fitness-for-service (FFS) Annex, (2008), Volume 2, ISBN 978-3-940923-01-1