Ispitivanje korozije bakarne trake u hidrokrekovanom baznom ulju u prisustvu različitih inhibitora Stručni rad

Glavni sadržaj članka

Apstrakt

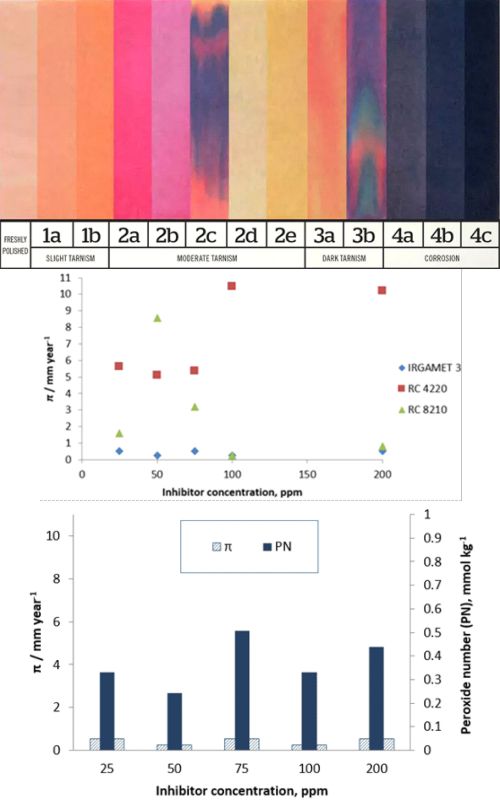

U ovom radu ispitivana je korozija bakra u hidrokrekovanom baznom ulju HC-6 u prisustvu različitih koncentracija aditiva za ekstremno visoke pritiske (EP aditiv). EP aditivi se koriste za smanjenje habanja u industrijskim primenama, pod uslovima velikog opterećenja. Budući da je većina ovih aditiva na bazi sumpora čija jedinjenja mogu biti korozivna na visokim temperaturama, njihova upotreba dovodi do korozije nekih materijala. Da bi se sprečila korozija bakra u baznom ulju sa EP aditivom dodana su tri komercijalna inhibitora korozije. Po hemijskom sastavu inhibitor RC 8210 je derivat dimerkaptotiadiazola, RC 4220 sintetički neutralan kalcijum sulfonat, a IRGAMET 39 je derivat tolutriazola. Efikasnost inhibitora praćena je u skladu sa stndardnom ASTM D-130 metodom, gravimetrijskom metodom, a oksidaciona stabilnost baznog ulja praćena je određivanjem vrednosti peroksidnog broja. Oksidacija je trajala 3 i 24 časa na 100⁰C ± 1⁰C. Ispitivanje je pokazalo da je IRGAMET 39 najefikasniji inhibitor u prisustvu EP aditiva u oba ispitivana vremena oksidacije.

Detalji članka

Broj časopisa

Rubrika

Ovaj rad je pod Creative Commons Aуторство-Nekomercijalno-Bez prerade 4.0 Internacionalna licenca.

Kada je rukopis prihvaćen za objavlјivanje, autori prenose autorska prava na izdavača. U slučaju da rukopis ne bude prihvaćen za štampu u časopisu, autori zadržavaju sva prava.

Na izdavača se prenose sledeća prava na rukopis, uklјučujući i dodatne materijale, i sve delove, izvode ili elemente rukopisa:

- pravo da reprodukuje i distribuira rukopis u štampanom obliku, uklјučujući i štampanje na zahtev;

- pravo na štampanje probnih primeraka, reprint i specijalnih izdanja rukopisa;

- pravo da rukopis prevede na druge jezike;

- pravo da rukopis reprodukuje koristeći fotomehanička ili slična sredstva, uklјučujući, ali ne ograničavajući se na fotokopiranje, i pravo da distribuira ove kopije;

- pravo da rukopis reprodukuje i distribuira elektronski ili optički koristeći sve nosioce podataka ili medija za pohranjivanje, a naročito u mašinski čitlјivoj/digitalizovanoj formi na nosačima podataka kao što su hard disk, CD-ROM, DVD, Blu-ray Disc (BD), mini disk, trake sa podacima, i pravo da reprodukuje i distribuira rukopis sa tih prenosnika podataka;

- pravo da sačuva rukopis u bazama podataka, uklјučujući i onlajn baze podataka, kao i pravo prenosa rukopisa u svim tehničkim sistemima i režimima;

- pravo da rukopis učini dostupnim javnosti ili zatvorenim grupama korisnika na osnovu pojedinačnih zahteva za upotrebu na monitoru ili drugim čitačima (uklјučujući i čitače elektonskih knjiga), i u štampanoj formi za korisnike, bilo putem interneta, onlajn servisa, ili putem internih ili eksternih mreža.

Kako citirati

Reference

Ahmad Khiara MS, Brown RCD, Lewin PL. Sacrificial Copper Strip Sensors for Sulfur Corrosion Detection in Transformer Oils. Measurement. 2019; 148: 1-6. https://doi.org/10.1016/j.measurement.2019.106887.

Alves SM, Schroeter RB, Bossardi JC dos S, Andrade CLF. Influence of EP additive on tool wear in drilling of compacted graphite iron. J. Braz. Soc. Mech. Sci. & Eng. 2011; 33: 197-202. https://doi.org/10.1590/S1678-58782011000200011.

Pawlak Z, Klamecki BE, Rauckyte T, Shpenkov GP, Kopkowski A. The tribochemical andmicellar aspects of cutting fluids. Tribol. Int. 2005; 38: 1–4. https://doi.org/10.1016/j.triboint.2004.04.004.

Boshui C, Nan Z, Kai L, Jianhua F. Enhanced Biodegradability, Lubricity and Corrosiveness of Lubricating Oil by Oleic Acid Diethanolamide Phosphate. Tribol. Ind. 2012; 34: 152-157. http://www.tribology.rs/journals/2012/2012-3/5.pdf.

Crutcher E. Copper Corrosion in the Absence of Corrosive Sulfur. In: Proceedings of TechCon US 2012 Conference. Austin, Texas, United States, 2012, pp 1-11.

Xue J, Yang X, Hu J. The Differences in Potential Corrosive Effects of Sulfides and Disulfides in Insulating Oils. IEEE T. Dielect. El. In. 2015; 22(1): 366-371. https://doi.org/10.1109/TDEI.2014.004210.

Venkata Lakshmi RA, Murthy TSR. Investigation of Copper corrosion in transformer oil. Int. J. Eng. Res. 2012; 1: 2278-0181. https://www.ijert.org/investigation-of-copper-corrosion-in-transformer-oil.

Ahmad Khiar MS, Brown RCD, Lewin PL. Detection of Sulfur Corrosion in Transformer Insulation Oils Using an Interdigitated Capacitive Sensor Based on Printed Circuit Board Technology. In: CEIDP 2017 - IEEE Conference on Electrical Insulation and Dielectric Phenomenon. Fort Worth, Texas, United States, 2017, pp. 278-281.

Wan T, Qian H, Zhou Z, Gong SK, Hu X, Feng B. Suppressive Mechanism of the Passivator Irgamet 39 on the Corrosion of Copper Conductors in Transformers. IEEE Trans. Dielectr. Electr. Insul. 2012; 19(2): 454-459. https://doi.org/10.1109/TDEI.2012.6180238.

Schaut A, Autru S, De Rop A, Eeckhoudt S. Effects of Irgamet®30 as Additive in Transformer Oil. IEEE Trans. Dielectr. Electr. Insul. 2012; 19(1): 175-180. https://doi.org/10.1109/TDEI.2012.6148516.

Cong H, Zhang M, Shu X, Li Q. Protective Performance of Different Passivators on Oil-Paper Insulation Containing Multiple Corrosive Sulphides. IEEE Access. 2019; 7: 4083-4090. https://doi.org/10.]09/ACCESS.2018.2888818.

Ling H, Jian S, Jun R, Qingjin M, Tsing Y. The adsorption of 2,5-dimercapto-1,3,4-thiadiazole (DMTD) on copper surface and its binding behavior. Chin. Sci. Bull. 2001; 46: 387–389. https://doi.org/10.1007/BF03183270.

Nassar AM, Ahmed NS, El-shazly RI, Abd el menem YK. Preparation and evaluation of the mixtures of sulfonate and phenate as lube oil additives. Int. J. Ind. Chem. 2017; 8:383-395. https://doi.org/10.1007/s40090-017-0128-x.

Zhongyi H, Liping X, Sheng H, Aixi C, Jianwei Q, Xisheng F. Tribological and Antioxidation Synergistic Effect Study of Sulfonate-Modified Nano Calcium Carbonate. PLOS ONE. 2013; 8(5): e62050. https://doi.org/10.1371/journal.pone.0062050.

OPTIMA GRUPA. https://optimagrupa.net/data/dokumenti/proizvodi/Tehni%C4%8Dki-list-HC-6.pdf. Acessed May 21, 2021.

Safety Data Sheet - Additive EP 7038 N. Additiv-Chemie Luers GmbH, Brendelweg 164, D-27755 Delmenhorst, Germany. Printing date 24.05.2015.

Safety Data Sheet - Irgamet 39. Ir https://vietducjsc.vn/upload/cdn/files/irgamet%2039%20msds(1).pdf Acessed May 21, 2021.

Safety Data Sheet - Additin RC 4220. https://www.tri-iso.com/rhein-chemie-additin-rc-4220.html Acessed May 21, 2021.

Safety Data Sheet - Additin RC 8210. https://www.yumpu.com/en/document/view/30819948/rc-8210-webshop-rhein-chemie Acessed May 21, 2021.

ASTM D 130 - 12: Standard Test Method for Corrosiveness to Copper from Petroleum Products by Copper Strip Test.

Stupišnek-Lisac E. Korozija i zaštita konstrukcijskih materijala. Zagreb, Fakultet kemijskog inženjerstva i tehnologije sveučilišta u zagrebu, 2007. ISBN: 978-953-6470-31-0

ASTM D 3703-99: Standard Test Method for Peroxide Number of Aviation Turbine Fuels.

Petrović ZR, Dugić PT, Aleksić VM, Botić TT, Kojić BN, Petrović RR. Uticaj kiselinom aktiviranog bentonita na oksidacionu stabilnost hidrokrekovanih baznih ulja. Glasnik hemičara, tehnologa i ekologa Republike Srpske. 2012; 7: 33-40. https://doi.org/10.7251/GHTE1207033P.

Zamberlin I. Aditivi za maziva. Maziva i podmazivanje. Zagreb: Savez Jugoslovenskih društava za primjenu goriva i maziva; 1986.