Optimizacija uslova sušenja raspršivanjem za proizvodnju praha ekstrakta Achillea millefolium Original scientific paper

Glavni sadržaj članka

Apstrakt

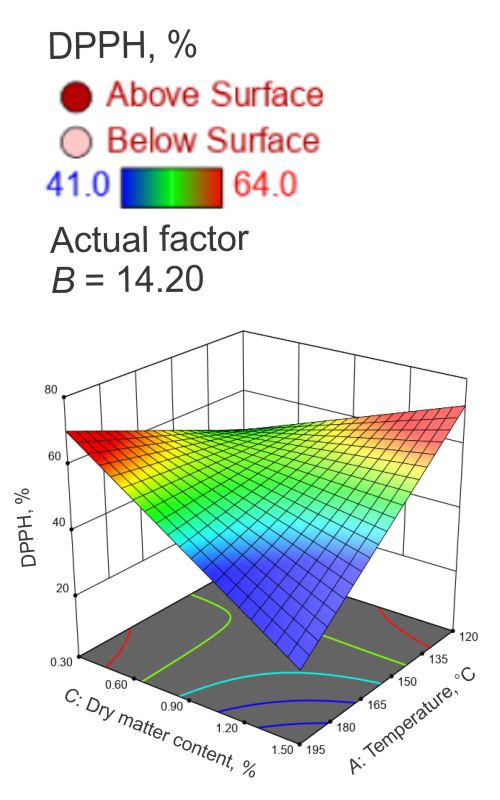

U radu je optimizovan postupak sušenja raspršivanjem tečnog ekstrakta hajdučke trave (Achillea millefolium L.) primenom metode odzivnih površina. Ispitan je uticaj temperature (120-195 °C), protoka tečnosti (3-16,5 cm3 min-1) i sadržaja suve materije u tečnom ekstraktu (0,3-1,5 %) na prinos sušenja, sadržaj polifenola i antioksidativnu aktivnost suvog ekstrakta. Pod ispitivanim uslovima prinos je drastično varirao (od 8 do 75%), dok je uticaj sušenja na sadržaj polifenola i antioksidativnu aktivnost dobijenog praha bio manji. Optimizovani uslovi za maksimalnu antioksidativnu aktivnost i maksimalan prinos suvog ekstrakta bili su sledeći:130 °C pri protoku od 7,5 cm3 min-1 tečnog ekstrakta sa 1,2 % suve materije. Pri optimalnim uslovima prinos sušenja je iznosio 66 %, dok je zabeležen blagi pad sadržaja polifenola u suvom ekstraktu u poređenju sa tečnim ekstraktom (145 mg ekvivalenta galne kiseline [GAE] po g suve materije naspram 152 mg GAE g-1, redom). Antioksidativna aktivnost suvog praha neznatno je smanjena u poređenju sa tečnim ekstraktom (neutralizacija DPPH (di(fenil)-(2,4,6-trinitrofenil)iminoazanijum) je bila 58 % naspram 64 %). U osušenom prahu hajdučke trave očuvana je antimikrobna aktivnost prema patogenim bakterijama Staphylococcus aureus (vrednost minimalne inhibitorne koncentracije (MIK) je bila 10 mg cm-3) i Pseudomonas aeruginosa (MIK vrednost je bila 20 mg cm-3).

Detalji članka

Broj časopisa

Rubrika

Ovaj rad je pod Creative Commons Aуторство-Nekomercijalno-Bez prerade 4.0 Internacionalna licenca.

Kada je rukopis prihvaćen za objavlјivanje, autori prenose autorska prava na izdavača. U slučaju da rukopis ne bude prihvaćen za štampu u časopisu, autori zadržavaju sva prava.

Na izdavača se prenose sledeća prava na rukopis, uklјučujući i dodatne materijale, i sve delove, izvode ili elemente rukopisa:

- pravo da reprodukuje i distribuira rukopis u štampanom obliku, uklјučujući i štampanje na zahtev;

- pravo na štampanje probnih primeraka, reprint i specijalnih izdanja rukopisa;

- pravo da rukopis prevede na druge jezike;

- pravo da rukopis reprodukuje koristeći fotomehanička ili slična sredstva, uklјučujući, ali ne ograničavajući se na fotokopiranje, i pravo da distribuira ove kopije;

- pravo da rukopis reprodukuje i distribuira elektronski ili optički koristeći sve nosioce podataka ili medija za pohranjivanje, a naročito u mašinski čitlјivoj/digitalizovanoj formi na nosačima podataka kao što su hard disk, CD-ROM, DVD, Blu-ray Disc (BD), mini disk, trake sa podacima, i pravo da reprodukuje i distribuira rukopis sa tih prenosnika podataka;

- pravo da sačuva rukopis u bazama podataka, uklјučujući i onlajn baze podataka, kao i pravo prenosa rukopisa u svim tehničkim sistemima i režimima;

- pravo da rukopis učini dostupnim javnosti ili zatvorenim grupama korisnika na osnovu pojedinačnih zahteva za upotrebu na monitoru ili drugim čitačima (uklјučujući i čitače elektonskih knjiga), i u štampanoj formi za korisnike, bilo putem interneta, onlajn servisa, ili putem internih ili eksternih mreža.

Kako citirati

Reference

Palhares RM, Gonçalves Drummond M, dos Santos Alves Figueiredo Brasil B, Pereira Cosenza G, das Graças Lins Brandao M, Oliveira G. Medicinal plants recommended by the world health organization: DNA barcode identification associated with chemical analyses guarantees their quality. PloS one. 2015;10:e0127866. https://doi.org/10.1371/journal.pone.0127866

Popovic V, Tatic M, Sikora V, Ikanovic J, Drazic G, Djukic V, Mihailovic B, Filipovic V, Dozet G, Jovanovic Lj, Stevanovic P. Variability of yield and chemical composition in soybean genotypes grown under different agro-ecological conditions of Serbia. Rom Agric Res. 2016;33:29-39.

Pham HNT, Nguyen VT, Vuong QV, Bowyer MC, Scarlett CJ. Effect of extraction solvents and drying methods on the physicochemical and antioxidant properties of Helicteres hirsuta Lour. leaves. Technol. 2015;3:285-301. https://doi.org/10.3390/technologies3040285

Azmin SNHM, Manan ZA, Alwi SRW, Chua LS, Mustaffa AA, Yunus NA. Herbal processing and extraction technologies. Sep Purif Rev. 2016;45:305-320. https://doi.org/10.1080/15422119.2016.1145395

Zhang QW, Lin LG, Ye WC. Techniques for extraction and isolation of natural products:a comprehensive review. Chin Med-UK. 2018;13:2-26. https://doi.org/10.1186/s13020-018-0177-x

Lakshmi T, Geetha RV, Roy A, Kumar SA. Yarrow (Achillea Millefolium Linn.) a herbal medicinal plant with broad therapeutic use-A review. Int J Pharm Sci Rev Res. 2011;9:136-141.

Cavalcanti AM, Baggio CH, Freitas CS, Rieck L, de Sousa RS, Da Silva-Santos JE, Mesia-Vela S, Marques MC. Safety and antiulcer efficacy studies of Achillea millefolium L. after chronic treatment in Wistar rats. J Ethnopharmacol. 2006;107:277-284. https://doi.org/10.1016/j.jep.2006.03.011

Benedek B, Kopp B. Achillea millefolium L. s.l. revisited:Recent findings confirm the traditional use. Wien Med Wochenschr. 2007;157:312-314. https://doi.org/10.1007/s10354-007-0431-9

Saeidnia S, Gohari AR, Mokhber-Dezfuli N, Kiuchi F. A review on phytochemistry and medicinal properties of the genus Achillea. DARU. 2011;19:173-86.

Othman L, Sleiman A, Abdel-Massih RM. Antimicrobial activity of polyphenols and alkaloids in Middle Eastern plants. Front Microbiol. 2019;10:911. https://doi.org/10.3389/fmicb.2019.00911

Milutinovic M, Radovanovic N, Corovic M, Siler-Marinkovic S, Rajilic-Stojanovic M, Dimitrijevic-Brankovic S. Optimisation of microwave-assisted extraction parameters for antioxidants from waste Achillea millefolium dust. Ind Crop Prod. 2015;77:333-341. https://doi.org/ 10.1016/j.indcrop.2015.09.007

Sasidharan S, Chen Y, Saravanan D, Sundram KM, Yoga Latha L. Extraction, isolation and characterization of bioactive compounds from plants' extracts. Afr J TraditComplem. 2011;8:1-10. https://doi.org/10.4314/ajtcam.v8i1.60483

Oliveira WP, Bott RB, Souza CRF. Manufacture of standardized dried extracts from medicinal Brazilian plants. Dry Technol. 2006;24:523-533. https://doi.org/10.1080/07373930600612073

Bakowska-Barczak AM, Kolodziejczyk PP. Black currant polyphenols:their storage stability and microencapsulation. Ind Crop Prod. 2011;34:1301-1309. https://doi.org/10.1016/j.indcrop.2010.10.002

Rocha GA, Favaro-Trindade CS, Grosso CRF. Microencapsulation of lycopene by spray drying:Characterization, stability and application of microcapsules. Food Bioprod Process. 2012;90:1-6. https://doi.org/10.1016/j.fbp.2011.01.001

Yatsu FKJ, Borghetti GS, Bassani VL. Technological characterization and stability of Ilex paraguariensis St. Hil. Aquifoliaceae (Mate) spray-dried powder. J Med Food. 2011;14:413-419. https://doi.org/10.1089/jmf.2010.0044

Souza CRF, Oliveira WP. Powder properties and system behaviour during spray drying of Bauhinia forficata link extract. Dry Technol. 2006;24:735-749. https://doi.org/10.1080/07373930600685905

Cortes-Rojas DF, Oliveira WP. Physicochemical properties of phytopharmaceutical preparations as affected by drying methods and carriers. Dry Technol. 2012;30:921-934. https://doi.org/10.1080/07373937.2012.666608

Amaro MI, Tajber L, Corrigan OI, Healy AM. Optimisation of spray drying process conditions for sugar nanoporousmicroparticles (NPMPs) intended for inhalation. Int J Pharm. 2011;421:99-109. https://doi.org/10.1016/j.ijpharm.2011.09.021

Nedovic V, Kalusevic A, Manojlovic V, Petrovic T, Bugarski B. Encapsulation Systems in the Food Industry. In:Advances in Food Process Engineering Research and Applications, Boston, MA:Springer Nature America, Inc;2013:229-253. https://doi.org/10.1007/978-1-4614-7906-2_13

Chegini GR, Ghobadian B. Spray dryer parameters for fruit juice drying. World J Agric Sci. 2007;3:230-236.

Patel RP, Patel MP, Suthar AM. Spray drying technology:an overview. Indian J Sci Technol. 2009;2:44-47. https://doi.org/10.17485/ijst/2009/v2i10.3

Andrea T, Marcela F, Lucia C, Esther F, Elena M, Simona M. Microencapsulation of lipase and savinase enzymes by spray drying using Arabic gum as wall material. JEAS. 2016;6:161-173. https://doi.org/10.1007/978-1-4614-7906-2_1310.4236/jeas.2016.64012

Ozmen L, Langrish TAG. An experimental investigation of the wall deposition of milk powder in a pilot-scale spray dryer. Dry Technol. 2003;21:1253-1272. https://doi.org/10.1081/DRT-120023179

Kudra T. Sticky region in drying:Definition and identification. Dry Technol. 2003;21:1457-1469. https://doi.org/10.1081/DRT-120024678

Montgomery DC. Response Surface Methods and Designs. In:Design and analysis of experiments, Eighth Edition John Wiley and Sons, Inc, New Jersey;2005:478.

Singleton V, Rossi JA. Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am J Enol Vitic. 1965;16:144-158.

Lee SK, Mbwambo Z, Chung H, Luyengi L, Gamez E, Mehta R, Kinghorn A, Pezzuto J. Evaluation of the antioxidant potential of natural products. Comb Chem High Throughput Screen.1998;1:35.

Sarker SD, Nahar L, Kumarasamy Y. Microtitre plate-based antibacterial assay incorporating resazurin as an indicator of cell growth, and its application in the in vitro antibacterial screening of phytochemicals. Methods. 2007;42:321-324. https://doi.org/10.1016/j.ymeth.2007.01.006

Tontul I, Topuz A. Spray-drying of fruit and vegetable juices:Effect of drying conditions on the product yield and physical properties. Trends Food Sci Tech. 2017;63:91-102. https://doi.org/10.1016/j.tifs.2017.03.009

Billon A, Bataille B, Cassanas G, Jacob M. Development of spray-dried acetaminophen microparticles using experimental designs. Int J Pharm. 2000;203:159-168. https://doi.org/10.1016/s0378-5173(00)00448-8

Nguyen DQ, Nguyen TH, Mounir S, Allaf K. Effect of feed concentration and inlet air temperature on the properties of soymilk powder obtained by spray drying. Dry Technol. 2017;36(7):817-829. https://doi.org/10.1080/07373937.2017.1357040

Prinn KB, Costantino HR, Tracy M. Statistical modeling of protein spray drying at the lab scale. AAPS Pharm Sci Tech. 2002;3:E4. https://doi.org/10.1208/pt030104

Poozesh S, Jafari SM, Akafuah NK. Interrogation of a new inline multi-bin cyclone for sorting of produced powders of a lab-scale spray dryer. Powder Technol. 2020;373:590-598. https://doi.org/10.1016/j.powtec.2020.07.012

Maurya M, Murphyb K, Kumarb S, Shib L, Leea G. Effects of process variables on the powder yield of spray-dried trehalose on a laboratory spray-dryer. Eur J Pharm Biopharm. 2005;59:565-573. https://doi.org/10.1016/j.ejpb.2004.10.002

Gallo L, Llabot Juan M, Allemandi D, Bucala V, Pina J. Influence of spray-drying operating conditions on Rhamnus purshiana (Cascara sagrada) extract powder physical properties. Powder Technol. 2011;208:205-214. https://doi.org/10.1016/j.powtec.2010.12.021

Telang AM, Thorat BN. Optimization of process parameters for spray drying of fermented soy milk. Dry Technol. 2010;28:1445-1456. https://doi.org/10.1080/07373937.2010.482694

Toneli J, Park K, Negreiros A, Murr F. Spray-drying process optimization of chicory root inulin. Dry Technol. 2010;28:369-379. https://doi.org/10.1080/07373931003645017

Mihajlovic T, Ibric S, Mladenovic A. Application of design of experiments and multilayer perceptron neural network in optimization of the spray-drying process. Dry Technol. 2011;29:1638-1647. https://doi.org/10.1080/07373937.2011.592960

Tee LH, Chuah L, Pin KY, Abdull Rashih A, Yusof YA. Optimization of spray drying process parameters of Piper betleL. (Sirih) leaves extract coated with maltodextrin. J Chem Pharm Res. 2012;4:1833-1841.

Goula AM, Adamopoulos KG. Spray drying of tomato pulp in dehumidified air:I. The effect on product recovery. J Food Eng. 2005;66:25-34. https://doi.org/10.1016/j.jfoodeng.2004.02.029

Tonon RV, Brabet C, Hubinger MD. Influence of process conditions on the physicochemical properties of acai (Euterpe oleraceae Mart) powder produced by spray drying. J Food Eng. 2008;88:411-418. https://doi.org/10.1016/j.jfoodeng.2008.02.029

Ramos FdeM, Oliveira CCMde, Soares ASP, Silveira Junior V. Assessment of differences between products obtained in conventional and vacuum spray dryer. Food Sci Technol. 2016;36 (4):724-729. https://doi.org/10.1590/1678-457X.09216

Jafari SM, Ghalenoei MG, Dehnad D. Influence of spray drying on water solubility index, apparent density, and anthocyanin content of pomegranate juice powder. Powder Technol. 2017;311:59-65. https://doi.org/10.1016/j.powtec.2017.01.070

Pinon-Balderrama CI, Leyva-Porras C, Teran-Figueroa Y, Espinosa-Solis V, Alvarez-Salas C, Saavedra-Leos MZ. Encapsulation of Active Ingredients in Food Industry by Spray-Drying and Nano Spray-Drying Technologies. Processes. 2020;8 (8):889. https://doi.org/10.3390/pr8080889

Eldridge JA, Repko D, Mumper RJ. Retention of polyphenolic species in spray-dried blackberry extract using mannitol as a thermoprotectant. J Med Food. 2014;17:1064-1069. https://doi.org/10.1089/jmf.2013.0177

Bastias-Montes JM, Choque-Chavez MC, Alarcon-Enos J, Quevedo-Leon R, Munoz-Farina O, Vidal-San-Martin C. Effect of spray drying at 150, 160, and 170 °C on the physical and chemical properties of maqui extract (Aristotelia chilensis (Molina) Stuntz). Chil J Agric Res. 2019;79 (1):144-152. https://doi.org/10.4067/S0718-58392019000100144

Souza V, Thomazini M, Balieiro J, Trindade C. Effect of spray drying on the physicochemical properties and color stability of the powdered pigment obtained from vinification byproducts of the Bordo grape (Vitis labrusca). Food Bioprod Process. 2015;93:39-50. https://doi.org/10.1016/j.fbp.2013.11.001

Turkmen N, Sari F, Velioglu YS. The effect of cooking methods on total phenolics and antioxidant activity of selected green vegetables. Food Chem. 2005;93:713-718. https://doi.org/10.1016/j.foodchem.2004.12.038

Sharma K, Ko EY, Assefa AD, Ha S, Nile SH, Lee ET, Park SW. Temperature-dependent studies on the total phenolics, flavonoids, antioxidant activities, and sugar content in six onion varieties. J Food Drug Anal. 2015;23:243-252. https://doi.org/10.1016/j.jfda.2014.10.005

Fang Z, Bhandari B. Effect of spray drying and storage on the stability of bayberry polyphenols. Food Chem. 2011;129:1139-1147. https://doi.org/10.1016/j.foodchem.2011.05.093

Edrisi M, Langrish TAG. Spray drying bioactive orange-peel extracts produced by Soxhlet extraction:Use of WPI, antioxidant activity and moisture sorption isotherms. LWT - Food Sci. Technol. 2016;72:1-8. https://doi.org/10.1016/j.lwt.2016.04.033

Frey FM. and Meyers R. Antibacterial activity of traditional medicinal plants used by Haudenosaunee peoples of New York State. BMC Complement Altern Med. 2010;10:64. https://doi.org/10.1186/1472-6882-10-64

Nostro A, Germano MP, D´Angelo V, Marino A, Cannatelli MA. Extraction methods and bioautography for evaluation of medicinal plant antimicrobial activity. Lett Appl Microbiol. 2000;30:379-384. https://doi.org/1046/j.1472-765x.2000.00731.x

Li Z-H, Cai M, Liu Y-S, Sun P-L, Luo S-L. Antibacterial activity and mechanisms of essential oil from Citrus medica L. var. sarcodactylis. Molecules. 2019;24:1577. https://doi.org/10.3390/molecules24081577

Tajik H, Jalali FSS, Sobhani A, Shahbazi Y, Zadeh MS. In vitro assessment of antimicrobial efficacy of alcoholic extract of Achillea millefolium in comparison with penicillin derivates. J Anim Vet Adv. 2008;7:508-511.

Lyss G, Glasl S, Jurenitsch J, Pahl HL, Merfort I. A sesquiterpene and sesquiterpene lactones from the Achillea millefolium group possess antiinflammatory properties but do not inhibit the transcription factor NF-γB. Pharm Pharmacol Lett. 2000;10:13-15.

Aljancic I, Vajs V, Menkovic N, Karadzic I, Juranic N, Milosavljevic S, Macura S. Flavones and sesquiterpene lactones from Achillea atrata subsp. multifida:antimicrobial activity. J Nat Prod. 1999;62:909-911. https://doi.org/10.1021/np980536m.