Taloženje litijum karbonata korišćenjem flokulanata sa različitim jonskim bazama Stručni rad

Glavni sadržaj članka

Apstrakt

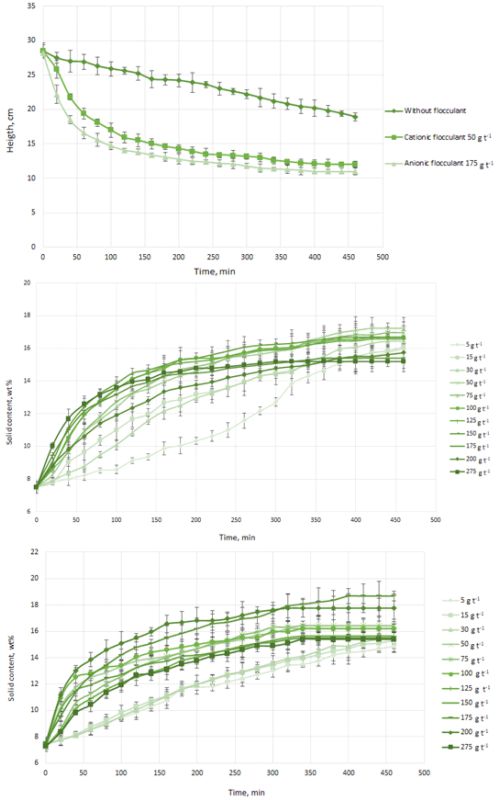

Litijum je postao metal od ogromnog interesa u celom svetu. Široka upotreba punjivih baterija za čitav niz primena podstakla je brzi rast potražnje za litijum karbonatom. Ovo jedinjenje se dobija kristalizacijom, reakcijom sa litijum hloridom (u rastvoru) uz dodavanjem natrijum karbonata. Niske stope taloženja u bazenima za isparavanje predstavljaju problem u procesu kristalizacije. Iz tog razloga, u ovom radu su izvršena ispitivanja sedimentacije minerala upotrebom dva tipa flokulanta sa različitim jonskim naelektrisanjem. Ispitivanja su izvedena na laboratorijskom nivou koristeći različite doze za svaki flokulant, a cilj istraživawa je bio postizanje povećanja asadržaja čvrstih materija u sedimentu. Anjonski flokulant je imao bolje performanse u poređenju sa kationnim flokulantom, povećavajući brzinu taloženja litijum karbonata do 6,5 puta. Međutim, slični sadržaji čvrstih materija dobijeni su upotrebom katjonskog flokulanta u dozi nižoj 3,5 puta, što ga čini flokulantom izbora sa ekonomskog stanovišta.

Detalji članka

Broj časopisa

Rubrika

Ovaj rad je pod Creative Commons Aуторство-Nekomercijalno-Bez prerade 4.0 Internacionalna licenca.

Kada je rukopis prihvaćen za objavlјivanje, autori prenose autorska prava na izdavača. U slučaju da rukopis ne bude prihvaćen za štampu u časopisu, autori zadržavaju sva prava.

Na izdavača se prenose sledeća prava na rukopis, uklјučujući i dodatne materijale, i sve delove, izvode ili elemente rukopisa:

- pravo da reprodukuje i distribuira rukopis u štampanom obliku, uklјučujući i štampanje na zahtev;

- pravo na štampanje probnih primeraka, reprint i specijalnih izdanja rukopisa;

- pravo da rukopis prevede na druge jezike;

- pravo da rukopis reprodukuje koristeći fotomehanička ili slična sredstva, uklјučujući, ali ne ograničavajući se na fotokopiranje, i pravo da distribuira ove kopije;

- pravo da rukopis reprodukuje i distribuira elektronski ili optički koristeći sve nosioce podataka ili medija za pohranjivanje, a naročito u mašinski čitlјivoj/digitalizovanoj formi na nosačima podataka kao što su hard disk, CD-ROM, DVD, Blu-ray Disc (BD), mini disk, trake sa podacima, i pravo da reprodukuje i distribuira rukopis sa tih prenosnika podataka;

- pravo da sačuva rukopis u bazama podataka, uklјučujući i onlajn baze podataka, kao i pravo prenosa rukopisa u svim tehničkim sistemima i režimima;

- pravo da rukopis učini dostupnim javnosti ili zatvorenim grupama korisnika na osnovu pojedinačnih zahteva za upotrebu na monitoru ili drugim čitačima (uklјučujući i čitače elektonskih knjiga), i u štampanoj formi za korisnike, bilo putem interneta, onlajn servisa, ili putem internih ili eksternih mreža.

Kako citirati

Reference

Saldaña M, Ayala L, Torres D, Toro N. Global sensitivity analyses of a neural networks model for a flotation circuit. Hemijska Industrija. 2020;74(4):247-256 https://doi.org/10.2298/HEMIND20060523S

Toro N, Briceño W, Pérez K, Cánovas M, Trigueros E, Sepúlveda R, Hernández P. Leaching of Pure Chalcocite in a Chloride Media Using Sea Water and Waste Water. Metals. 2019;9(7):780 https://doi.org/10.3390/met9070780

Toro N, Pérez K, Saldaña M, Jeldres RI, Jeldres M, Cánovas M. Dissolution of pure chalcopyrite with manganese nodules and waste water. Journal of Materials Research and Technology. 2019 https://doi.org/10.1016/j.jmrt.2019.11.020

Torres D, Pérez K, Trigueros E, Jeldres R, Salinas-Rodríguez E, Robles P, Toro N. Reducing-effect of chloride for the dissolution of black copper. Metals (Basel). 2020;10(1) https://doi.org/10.3390/met10010123

Pérez K, Toro N, Campos E, González J, Jeldres R, Nazer A, Rodriguez MH. Extraction of Mn from Black Copper Using Iron Oxides from Tailings and Fe2+ as Reducing Agents in Acid Medium. Metals (Basel). 2019;9:1112 https://doi.org/10.3390/met9101112

Toro N, Robles P, Jeldres R. Seabed mineral resources, an alternative for the future of renewable energy: A critical review. Ore Geology Reviews. August 2020:103699 https://doi.org/10.1016/j.oregeorev.2020.103699

Toro N, Jeldres R, Órdenes J, Robles P, Navarra A. Manganese Nodules in Chile , an Alternative for the Production of Co and Mn in the Future — A Review. Minerals. 2020;10(674):1-19 https://doi.org/10.3390/min10080674

Heelan J, Gratz E, Zheng Z, Wang Q, Chen M, Apelian D, Wang Y. Current and Prospective Li-Ion Battery Recycling and Recovery Processes. Jom. 2016;68(10):2632-2638 http://doi.org/10.1007/s11837-016-1994-y

Maxwell P, Mora M. Lithium and Chile: looking back and looking forward. Mineral Economics. 2020;33(1-2):57-71 https://doi.org/10.1007/s13563-019-00181-8

Pinna EG, Drajlin DS, Toro N, Rodriguez MH. Kinetic modeling of the leaching of LiCoO2 with phosphoric acid. Journal of Materials Research and Technology. 2020;9(6):14017-14028 https://doi.org/10.1016/j.jmrt.2020.09.109

Donoso, F; Garay, V; Cantallopts J. International Lithium Market and Its Potential in Chile. Chile; 2017.

Gruber PW, Medina PA, Keoleian GA, Kesler SE, Everson MP, Wallington TJ. Global lithium availability: A constraint for electric vehicles? Journal of Industrial Ecology. 2011;15(5):760-775 https://doi.org/10.1111/j.1530-9290.2011.00359.x

U.S. Geological Survey. Mineral Commodity Summaries 2020.; 2020.

Velásquez C, Cabrera V. Small-scale lithium production from brines. In: Lima, Perú; 2018:19-21.

Lunde Seefeldt J. Lessons from the Lithium Triangle: Considering Policy Explanations for the Variation in Lithium Industry Development in the "Lithium Triangle" Countries of Chile, Argentina, and Bolivia. Politics and Policy. 2020;48(4):727-765.

Chen QB, Ji ZY, Liu J, Zhao YY, Wang SZ, Yuan JS. Development of recovering lithium from brines by selective-electrodialysis: Effect of coexisting cations on the migration of lithium. Journal of Membrane Science. 2018;548(8):408-420 https://doi.org/10.1016/j.memsci.2017.11.040

Miranda C. Background for a Public Policy in Strategic Minerals: Lithium. Chile; 2009.

Boryta, Kullberg T. Production of lithium compounds directly from lithium containing brines, in: Google Patents. 2007;2(12).

Jandová J, Dvořák P, Vu HN. Processing of zinnwaldite waste to obtain Li2CO3. Hydrometallurgy. 2010;103(1-4):12-18 https://doi.org/10.1016/j.hydromet.2010.02.010

Taborga P, Brito I, Graber TA. Effect of additives on size and shape of lithium carbonate crystals. Journal of Crystal Growth. 2017;460(November 2016):5-12 https://doi.org/10.1016/j.jcrysgro.2016.12.001

Han B, Anwar UI Haq R, Louhi-Kultanen M. Lithium carbonate precipitation by homogeneous and heterogeneous reactive crystallization. Hydrometallurgy. 2020;195(October 2019):105386 https://doi.org/10.1016/j.hydromet.2020.105386

Riveros Zapata A, Ale Ruiz L, Lezama J, Erdmann E. Lithium carbonate production: Simulation using aspen plus. Salta, Argentina; 2018.

Schoenmann, Hales, Bedell D. Strategies for instru-mentation and control of thickeners and other solid–liquid separation circuits. Mineral Processing Plant Design, Practice, and Control. 2002;2:2164-2173.

Teerikoski S. Optimal Control of Clarifier-Thickeners. Uppsala, Sweden; 2017 http://uu.diva-portal.org/smash/get/diva2:1088256/FULLTEXT01.pdf

Díaz J. Coagulants - organic and inorganic flocculants made from plants and scrap metal recycling, for the treatment of polluted water. McKinsey Quarterly. 2014;2(1):1-22.

Elhaei R, Kharrat R, Madani M. Stability, flocculation, and rheological behavior of silica suspension-augmented polyacrylamide and the possibility to improve polymer flooding functionality. Journal of Molecular Liquids. 2021;322:114572 https://doi.org/10.1016/j.molliq.2020.114572

Wilkomirsky I. Extraction and refining of non-ferrous metals: Lithium; Metallurgical engineering department, Universidad de Concepción, Concepción, Chile 2008:1-25.

Salam AM, Örmeci B, Simms PH. Determination of optimum polymer dosage for dewatering of oil sands tailings using torque rheology. Journal of Petroleum Science and Engineering. 2021;197 (August 2020) https://doi.org/10.1016/j.petrol.2020.107986

Concha F. Filtration and separation manual; Metallurgical engineering department, Universidad de Concepción, Concepción, Chile 2001;(January 2001):234-308.