Proračun i optimizacija skrubera za prečišćavanja otpadnih gasova koji sadrže amonijak Stručni rad

Glavni sadržaj članka

Apstrakt

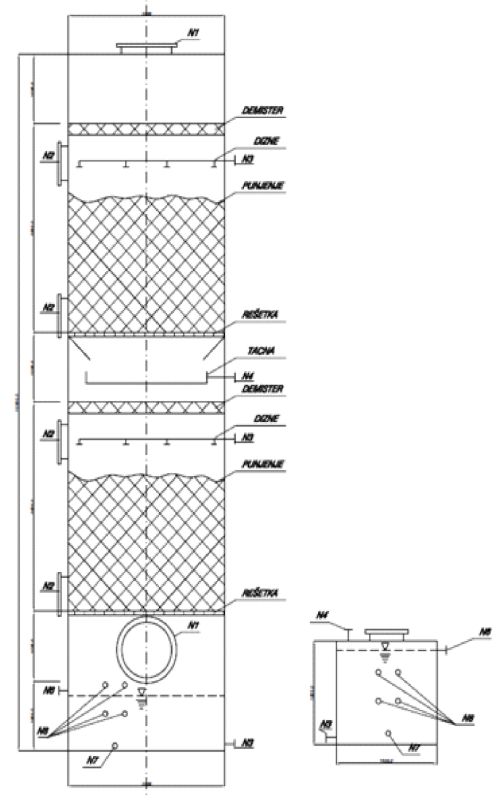

U ovom radu izvršen je proračun i dimenzionisanje dvostepenog skrubera sa pakovanim slojem za prečišćavanje otpadnog gasa iz hemijske industrije koji sadrži amonijak u koncentraciji od 1400 mg m-3. Za proračun su korišćene osnovne jednačine materijalnog bilansa, ravnotežni podaci, kao i generalizovana korelacija za pad pritiska. Prilikom proračuna i analize različitih konfiguracija korišćen je Katmar softver koji koristi generalizovanu korelaciju za pad pritiska za određivanje prečnika skrubera na osnovu dozvoljenog pada pritiska i udaljenosti od uslova plavljenja. Utvrđeno je da se optimalni rezultati postižu u dvostepenom uređaju, korišćenjem sumporne kiseline (70 %) za hemisorpciju amonijaka. Kao punjenje u koloni odabrani su Palovi prstenovi dimenzije 50 mm izrađeni od polipropilena. U radu su analizirane kolone prečnika Dc = 2; 2,1 i 2,2 m. Sa aspekta protoka tečne faze prečnik kolone Dc = 2 m zadovoljava, a prema specifikaciji punjenja pad pritiska kroz ukupnu visinu sloja punjenja je oko 900 Pa. Utvrđeno je da se gradijent pritiska, a samim tim i ukupni pad pritiska u koloni smanjuje povećanjem prečnika kolone. Međutim, sa povećanjem prečnika kolone raste minimalni protok tečne faze potreban za kvašenje punjenja, te se potreban protok tečne faze povećava. Uzimajući u obzir sve procesne parametre, kao i zahtevanu efikasnost prečišćavanja otpadnog gasa, predložena je optimalna konfiguracija uređaja.

Detalji članka

Broj časopisa

Rubrika

Ovaj rad je pod Creative Commons Aуторство-Nekomercijalno-Bez prerade 4.0 Internacionalna licenca.

Kada je rukopis prihvaćen za objavlјivanje, autori prenose autorska prava na izdavača. U slučaju da rukopis ne bude prihvaćen za štampu u časopisu, autori zadržavaju sva prava.

Na izdavača se prenose sledeća prava na rukopis, uklјučujući i dodatne materijale, i sve delove, izvode ili elemente rukopisa:

- pravo da reprodukuje i distribuira rukopis u štampanom obliku, uklјučujući i štampanje na zahtev;

- pravo na štampanje probnih primeraka, reprint i specijalnih izdanja rukopisa;

- pravo da rukopis prevede na druge jezike;

- pravo da rukopis reprodukuje koristeći fotomehanička ili slična sredstva, uklјučujući, ali ne ograničavajući se na fotokopiranje, i pravo da distribuira ove kopije;

- pravo da rukopis reprodukuje i distribuira elektronski ili optički koristeći sve nosioce podataka ili medija za pohranjivanje, a naročito u mašinski čitlјivoj/digitalizovanoj formi na nosačima podataka kao što su hard disk, CD-ROM, DVD, Blu-ray Disc (BD), mini disk, trake sa podacima, i pravo da reprodukuje i distribuira rukopis sa tih prenosnika podataka;

- pravo da sačuva rukopis u bazama podataka, uklјučujući i onlajn baze podataka, kao i pravo prenosa rukopisa u svim tehničkim sistemima i režimima;

- pravo da rukopis učini dostupnim javnosti ili zatvorenim grupama korisnika na osnovu pojedinačnih zahteva za upotrebu na monitoru ili drugim čitačima (uklјučujući i čitače elektonskih knjiga), i u štampanoj formi za korisnike, bilo putem interneta, onlajn servisa, ili putem internih ili eksternih mreža.

Kako citirati

Reference

Bhatia MV. Packed Tower and Absorption Design. In Cheremisinoff PN, Young RA, eds. Air Pollution Control and Design Handbook. New York, NY: Marcel Dekker; 1977. https://doi.org/10.1007/978-981-13-7488-3

Richards JR. Control of Gaseous Emissions. APTI Course 415. U.S. Environmental Protection Agency; 1995. https://www.4cleanair.org/wp-content/uploads/APTI/415combined.pdf

Srivastava RK, Jozewicz W, Singer C. SO2 scrubbing technologies. Environ Prog. 2001; 20(4): 219-28. https://doi.org/10.1002/ep.670200410

Wet Scrubber System Study. NTIS Report PB-213016; U.S. EPA, Research Triangle Park, NC, 1972. https://nepis.epa.gov/Exe/ZyNET.exe/9101LF9J.txt?ZyActionD=ZyDocument&Client=EPA&Index=Prior%20to%201976&Docs=&Query=&Time=&EndTime=&SearchMethod=1&TocRestrict=n&Toc=&TocEntry=&QField=&QFieldYear=&QFieldMonth=&QFieldDay=&UseQField=&IntQFieldOp=0&ExtQFieldOp=0&XmlQuery=&File=D%3A%5CZYFILES%5CINDEX%20DATA%5C70THRU75%5CTXT%5C00000023%5C9101LF9J.txt&User=ANONYMOUS&Password=anonymous&SortMethod=h%7C-&MaximumDocuments=1&FuzzyDegree=0&ImageQuality=r75g8/r75g8/x150y150g16/i425&Display=hpfr&DefSeekPage=x&SearchBack=ZyActionL&Back=ZyActionS&BackDesc=Results%20page&MaximumPages=1&ZyEntry=1&slide#

Joseph GTPE, Beachler DS. Scrubber System Operation Review., 2nd ed., North Carolina State University; 1998. https://www.studocu.com/es-mx/document/universidad-veracruzana/operaciones-fisicas-unitarias/design-review-of-absorbers-used-for-gaseous-pollutants-removal/10718576

Hesketh HD. Wet scrubbers. 2nd ed., New York, NY: Routledge; 2017. https://doi.org/10.1201/9780203733899

U.S. Environmental Protection Agency, 1998. Wet-Film (Packed Tower) Scrubbers. 2012; 1-15. www.yosemite.epa.gov/oaqps/eogtrain.nsf.gov

Schifftner KC, Hesketh HE. Wet scrubbers. United States: 1983. https://www.osti.gov/biblio/6626241

McCabe Wl, Smith JC, Harriot P Unit Operations of Chemical Engineering, McGraw-Hill International Editions, New York, 1993. ISBN 0-07-044844-2. https://evsujpiche.files.wordpress.com/2014/06/unit-operations-of-chemical-engineering-5th-ed-mccabe-and-smith.pdf

Strigle RE Jr. Packed Tower Design and Applications - Random and Structured Packings. 2nd ed., Houston, London, Paris, Zurich, Tokyo: Gulf Publishing Company; 1994. ISBN 0-88415-179-4. https://www.scribd.com/doc/81675448/Packed-Tower-Design-and-Applications-R-F-Strigle-1994

Phillips J. Control and pollution prevention options for ammonia emissions: VIGYAN Inc. (Technical Report), United States; 1995. https://www.osti.gov/biblio/104094

Hadlocon LJ, Manuzon RB, Zhao L. Optimization of ammonia absorption using acid spray wet scrubbers. Transactions of the ASABE. 2014; 57(2): 647-659. https://doi.org/10.13031/trans.57.10481

Ashtari AK, Majd AM, Riskowski GL, Mukhtar S, Zhao L. Removing ammonia from air with a constant pH, slightly acidic water spray wet scrubber using recycled scrubbing solution. Front Environ Sci Eng. 2016; 10; 3. https://doi.org/10.1007/s11783-016-0869-3

Piche S, Larachi F, Grandjean BPA. Flooding Capacity in Packed Towers: Database, Correlations, and Analysis. Ind. Eng Chem Res. 2001; 40: 476-487. https://doi.org/10.1021/ie000486s

Packed Column Calculator, Version 2.1, March 2010, Katmar Software, http://www.KatmarSoftware.com

Leva M. Tower Packings and Packed Tower Design. United States Stoneware Company: Akron, OH, 1953. https://babel.hathitrust.org/cgi/pt?id=mdp.39015000476294&seq=11

Eckert JS. How tower packings behave. Chem Eng. 1975; 2(8): 70-76. https://www.coursehero.com/file/p5fbd1p/Eckert-J-S-1975-How-tower-packings-behave-Chemical-Engineering-v-82-pp-70-Ellis/

Robbins L. Improve pressure drop prediction with a new correlation. Chem Eng Prog. 1991; 87(5): 87-90. ISSN 0360-7275. https://api.semanticscholar.org/CorpusID:113682503

The Pall Ring Company Ltd., UK. https://www.pallrings.co.uk/products/pall-rings-plastic/