Mehanička svojstva površinski modifikovane legure magnezijuma AZ61 sa nanočesticama aluminijum oksida i titanijum dioksida obradom putem tehnike trenja sa mešanjem Stručni rad

Glavni sadržaj članka

Apstrakt

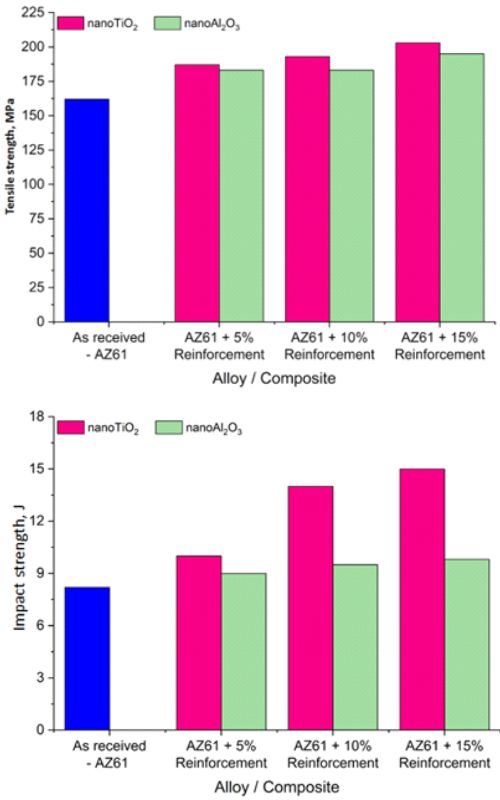

U ovom radu su prikazani rezultati istraživanja mehaničkih osobina površinski modifikovane legure magnezijuma AZ61, ojačane nanočesticama Al2O3 i TiO2 primenom tehnike trenja sa mešanjem (engl. friction stir processing - FSP). Površinski modifikovane legure AZ61 su proizvedene dodavanjem različitih količina nanočestica Al2O3 i TiO2 (5, 10 i 15 vol.%). Mikrostruktura dobijenih površinskih kompozita pokazuje ujednačenu disperziju dodatih nanočestica, što je rezultiralo poboljšanjem njihovih mehaničkih svojstava primenom FSP. Ojačavanjem legure nanočesticama TiO2 krajnja zatezna, udarna i mikro-tvrdoća su poboljšane za 20, 45 i 67 %, redom, u poređenju sa livenom legurom. Rezultati ove studije ukazuju da ojačana legura AZ61 Mg može biti potencijalni materijal za primenu u automobilskoj industriji, jer poseduje veliku čvrstoću i malu specifičnu težinu.

Detalji članka

Broj časopisa

Rubrika

Ovaj rad je pod Creative Commons Aуторство-Nekomercijalno-Bez prerade 4.0 Internacionalna licenca.

Kada je rukopis prihvaćen za objavlјivanje, autori prenose autorska prava na izdavača. U slučaju da rukopis ne bude prihvaćen za štampu u časopisu, autori zadržavaju sva prava.

Na izdavača se prenose sledeća prava na rukopis, uklјučujući i dodatne materijale, i sve delove, izvode ili elemente rukopisa:

- pravo da reprodukuje i distribuira rukopis u štampanom obliku, uklјučujući i štampanje na zahtev;

- pravo na štampanje probnih primeraka, reprint i specijalnih izdanja rukopisa;

- pravo da rukopis prevede na druge jezike;

- pravo da rukopis reprodukuje koristeći fotomehanička ili slična sredstva, uklјučujući, ali ne ograničavajući se na fotokopiranje, i pravo da distribuira ove kopije;

- pravo da rukopis reprodukuje i distribuira elektronski ili optički koristeći sve nosioce podataka ili medija za pohranjivanje, a naročito u mašinski čitlјivoj/digitalizovanoj formi na nosačima podataka kao što su hard disk, CD-ROM, DVD, Blu-ray Disc (BD), mini disk, trake sa podacima, i pravo da reprodukuje i distribuira rukopis sa tih prenosnika podataka;

- pravo da sačuva rukopis u bazama podataka, uklјučujući i onlajn baze podataka, kao i pravo prenosa rukopisa u svim tehničkim sistemima i režimima;

- pravo da rukopis učini dostupnim javnosti ili zatvorenim grupama korisnika na osnovu pojedinačnih zahteva za upotrebu na monitoru ili drugim čitačima (uklјučujući i čitače elektonskih knjiga), i u štampanoj formi za korisnike, bilo putem interneta, onlajn servisa, ili putem internih ili eksternih mreža.

Kako citirati

Reference

Huang, S.J, Subramani, M, Chiang, CC. Effect of hybrid reinforcement on microstructure and mechanical properties of AZ61 magnesium alloy processed by stir casting method.Compos Commun. 2021; 25: 100772. https://doi.org/10.1016/j.coco.2021.100772

Billard, A., Maury, F., Aubry, P., Balbaud-Célérier, F., Bernard, B., Lomello, F., Maskrot, H., Meillot, E., Michau, A. and Schuster, F. Emerging processes for metallurgical coatings and thin films. CR Phys. 2018: 19; 755-768.https://doi.org/10.1016/j.crhy.2018.10.005

Mahoney MW, Binget WH, Mishra RS. Microstructural Modification and Resultant Properties of Friction Stir Processed Cast NiAl Bronze. Mater Sci Forum. 2003; 426: 2843-2853. https://doi.org/10.4028/www.scientific.net/MSF.426-432.2843

Ammouri A H, Kridli G, Ayoub G, Hamade RF. Relating grain size to the Zener–Hollomon parameter for twin-roll-cast AZ31B alloy refined by friction stir processing. J Mater Process Technol. 2015; 222: 301-306.https://doi.org/10.1016/j.jmatprotec.2015.02.037

Xue P, Xiao BL, Ma ZY. Enhanced strength and ductility of friction stir processed Cu–Al alloys with abundant twin boundaries.Scr Mater. 2013; 68: 751-754. https://doi.org/10.1016/j.scriptamat.2013.01.003

Chai F, Zhang D, Li Y, Microstructures and tensile properties of submerged friction stir processed AZ91 magnesium alloy. J Magnes Alloy. 2015; 3: 203–209. https://doi.org/10.1016/j.jma.2015.08.001

Patel V, Li W, Vairis A, Badheka V. Recent development in friction stir processing as a solid-state grain refinement technique: microstructural evolution and property enhancement.Crit Rev Solid State Mater Sci. 2019; 44: 378-426. https://doi.org/10.1080/10408436.2018.1490251

Satish Kumar T, Shalini S, Thankachan T. Friction stir processing based surface modification of AZ31 magnesium alloy. Mater Manuf Process. 2023; 38(11): 1426-1435. https://doi.org/10.1080/10426914.2023.2165670

Aatthisugan I, Rose AR, Jebadurai DS. Mechanical and wear behaviour of AZ91D magnesium matrix hybrid composite reinforced with boron carbide and graphite.J Magnes Alloy. 2017; 5: 20-25. https://doi.org/10.1016/j.jma.2016.12.004

Balaji E, Sathiya Moorthy R. Investigation on Mechanical and Wear Properties of ZE43 Magnesium Composites Reinforced with Silicon Nitride by Friction Stir Processing. Silicon. 2022; 6: 11881-11890. https://doi.org/10.1007/s12633-022-01914-1

Sagar P, Handa A, Kumar G. Metallurgical, mechanical and tribological behavior of Reinforced magnesium-based composite developed Via Friction stir processing. Proc Inst Mech Eng E: 2022; 236: 1440-1451. https://doi.org/10.1177/09544089211063099

Adetunla A, Akinlabi E. Influence of reinforcements in friction stir processed magnesium alloys: insight in medical applications. Mater Res Express. 2018; 6: 025406. https://doi.org/10.1088/2053-1591/aaeea8

Gobara M, Shamekh M, Akid R. Improving the corrosion resistance of AZ91D magnesium alloy through reinforcement with titanium carbides and borides. J Magnes Alloy. 2015; 39: 112-120. https://doi.org/10.1016/j.jma.2015.03.002

Gangil N, Nagar H, Mohammed SMAK, Singh D, Siddiquee AN, Maheshwari S, Chen DL. Fabrication of magnesium–NiTip composites via friction stir processing: Effect of tool profile. Metals. 2020; 10: 1425. https://doi.org/10.3390/met10111425

Dinaharan I, Zhang S, Chen G, Shi Q. Titanium particulate reinforced AZ31 magnesium matrix composites with improved ductil¬ity prepared using friction stir processing. Mater Sci Eng. 2020; 772: 138793. https://doi.org/10.1016/j.msea.2019.138793

Das U, Toppo V. Effect of Tool Rotational Speed on Temperature and Impact. Mater Today Proc. 2018; 5: 6170-6175. https://doi.org/10.1016/j.matpr.2017.12.223

Thirumalvalavan S, Senthilkumar N, Experimental Investigation and Optimization of HVOF Spray parameters on wear resistance behaviour of Ti-6Al-4V Alloy, ,C R Acad Bulg Sci.2019; 72: 665-674. https://doi.org/10.7546/CRABS.2019.05.15