Otpornost prema lomu, tvrdoća i mikrostruktura šavnih cevi različitog prečnika izrađenih od čelika P235TR1 Naučni rad

Glavni sadržaj članka

Apstrakt

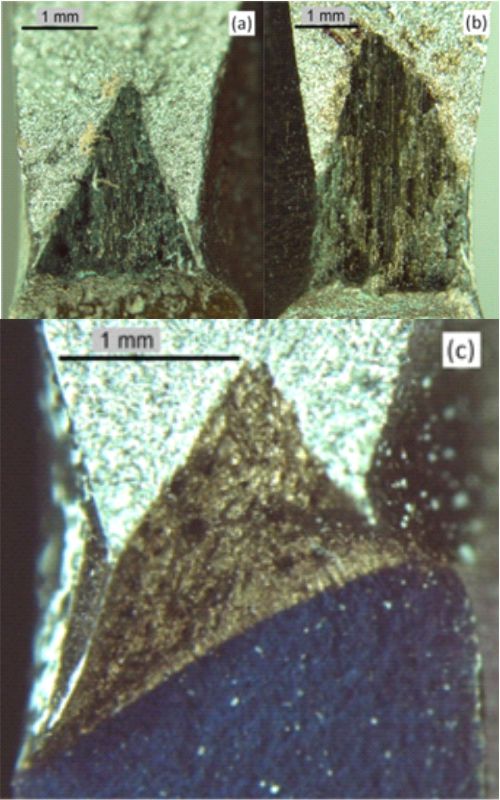

Čelični cevovodi u industrijskim postrojenjima se sastoje od različitih elemenata, uključujući bešavne i/ili zavarene (šavne) cevi. Osobine šavnih cevi, uključujući ponašanje materijala cevi pri lomu, zavise i od osnovnog metala i od metala šava. U ovom radu razmatrane su dve šavne cevi različitih prečnika, izrađene od čelika P235TR1. Tvrdoća i mikrostruktura su analizirane na uzorcima isečenim iz cevi u zoni šava, da bi se odredio uticaj heterogenosti. Otpornost prema lomu materijala cevovoda, tj. oba osnovna metala i oba šava, je određena na osnovu ispitivanja epruveta oblika prstena sa oštrim koncentratorima napona, predloženih u prethodnim studijama. Poređenjem krivih otpornosti prema rastu prsline određene su razlike između dve ispitivane cevi, kao i uticaj heterogenosti izazvan postojanjem zavarenog spoja. Razmotren je uticaj oblika početnog koncentratora napona, oštrog žleba odnosno zamorne početne prsline.

Detalji članka

Broj časopisa

Rubrika

Ovaj rad je pod Creative Commons Aуторство-Nekomercijalno-Bez prerade 4.0 Internacionalna licenca.

Kada je rukopis prihvaćen za objavlјivanje, autori prenose autorska prava na izdavača. U slučaju da rukopis ne bude prihvaćen za štampu u časopisu, autori zadržavaju sva prava.

Na izdavača se prenose sledeća prava na rukopis, uklјučujući i dodatne materijale, i sve delove, izvode ili elemente rukopisa:

- pravo da reprodukuje i distribuira rukopis u štampanom obliku, uklјučujući i štampanje na zahtev;

- pravo na štampanje probnih primeraka, reprint i specijalnih izdanja rukopisa;

- pravo da rukopis prevede na druge jezike;

- pravo da rukopis reprodukuje koristeći fotomehanička ili slična sredstva, uklјučujući, ali ne ograničavajući se na fotokopiranje, i pravo da distribuira ove kopije;

- pravo da rukopis reprodukuje i distribuira elektronski ili optički koristeći sve nosioce podataka ili medija za pohranjivanje, a naročito u mašinski čitlјivoj/digitalizovanoj formi na nosačima podataka kao što su hard disk, CD-ROM, DVD, Blu-ray Disc (BD), mini disk, trake sa podacima, i pravo da reprodukuje i distribuira rukopis sa tih prenosnika podataka;

- pravo da sačuva rukopis u bazama podataka, uklјučujući i onlajn baze podataka, kao i pravo prenosa rukopisa u svim tehničkim sistemima i režimima;

- pravo da rukopis učini dostupnim javnosti ili zatvorenim grupama korisnika na osnovu pojedinačnih zahteva za upotrebu na monitoru ili drugim čitačima (uklјučujući i čitače elektonskih knjiga), i u štampanoj formi za korisnike, bilo putem interneta, onlajn servisa, ili putem internih ili eksternih mreža.

Kako citirati

Funding data

-

Ministarstvo Prosvete, Nauke i Tehnološkog Razvoja

Grant numbers 451-03-47/2023-01/200135

Reference

Moattari M, Moshayedi H, Sattari-Far I. Application of new constraint based Master Curve in fracture assessment of pressure vessels. Int J Pres Ves Pip. 2019; 174: 25–31. https://doi.org/10.1016/j.ijpvp.2019.05.009

Golubović T, Sedmak A, Spasojević Brkić V, Kirin S, Veg E. Welded joints as critical regions in pressure vessels - case study of vinyl chloride monomer storage tank. Hem Ind. 2018; 72: 177–182. https://doi.org/10.2298/HEMIND171009006G

Murtaza UT, Javed Hyder M. Fracture analysis of the set-in nozzle of a PWR reactor pressure vessel - Part 1: Determination of critical crack. Eng Fract Mech. 2018; 192: 343–361. https://doi.org/10.1016/j.engfracmech.2016.03.049

Mitrović N, Petrović A, Milošević M, Momčilović N, Mišković Ž, Maneski T, Popović P. Experimental and numerical study of globe valve housing. Hem Ind. 2017; 71: 251–257. https://doi.org/10.2298/HEMIND160516035M

Šarkoćević Ž, Rakin M, Arsić M, Sedmak A. Fabrication of high strength seam welded steel tubes and quality indicator testing. Struct Integr Life. 2008; 8: 81–98. http://divk.inovacionicentar.rs/ivk/ivk08/ivk0802-1.html

Choupani N, Asghari V, Kurtaran, H. Fracture Characterization of Base Metal, Seam Weld, and Girth Weld of Welded Line Pipe Steel at Room and Low Temperatures. J Mater Eng Perf. 2021; 30: 1046–1053. https://dx.doi.org/10.1007/s11665-020-05431-3

Angeles-Herrera D, Albiter-Hernández A, Cuamatzi-Meléndez R, González-Velázquez JL. Fracture toughness in the circumferential-longitudinal and circumferential-radial directions of longitudinal weld API 5L X52 pipeline using standard C(T) and nonstandard curved SE(B) specimens. Int J Fract. 2014; 188: 251–256. https://dx.doi.org/10.1007/s10704-014-9949-1

Chen Z, Chen X, Zhou T. Microstructure and Mechanical Properties of J55ERW Steel Pipe Processed by On-Line Spray Water Cooling. Metals. 2017; 7: paper No. 150. https://doi.org/10.3390/met7040150

Van Minnebruggen K, Hertelé S, Thibaux P, De Waele W. Effects of specimen geometry and anisotropic material response on the tensile strain capacity of flawed spiral welded pipes. Eng Fract Mech. 2015; 148: 350–362. https://doi.org/10.1016/j.engfracmech.2015.04.031

Gajdos L, Sperl M. Evaluating the integrity of pressure pipelines by fracture mechanics. In: Applied Fracture Mechanics, London: InTech Publishing; 2012: 283–310. https://dx.doi.org/10.5772/51804

Zhang ZL, Xu J, Nyhus B, Østby E. SENT (single edge notch tension) methodology for pipeline applications. In: Proceedings of the 18th European Conference on Fracture, Dresden, Germany, 2010, pp. 1-8, published on CD.

Xu J, Zhang ZL, Østby E, Nyhus B, Sun DB. Effects of crack depth and specimen size on ductile crack growth of SENT and SENB specimens for fracture mechanics evaluation of pipeline steels. Int J Pres Ves Pip. 2009; 86: 787–797. https://dx.doi.org/10.1016/j.ijpvp.2009.12.004

Xu J, Zhang ZL, Østby E, Nyhus B, Sun DB. Constraint effect on the ductile crack growth resistance of circumferentially cracked pipes. Eng Fract Mech. 2010; 77: 671–684. https://dx.doi.org/10.1016/j.engfracmech.2009.11.005

Mahajan G, Saxena S, Mohanty A. Numerical characterization of compact pipe specimen for stretch zone width assessment. Fatigue Fract Engng Mater Struct. 2016; 39: 859–865. https://dx.doi.org/10.1111/ffe.12400

Koo JM, Park S, Seok CS. Evaluation of fracture toughness of nuclear piping using real pipe and tensile compact pipe specimens. Nucl Eng Design. 2013; 259: 198–204. https://dx.doi.org/10.1016/j.nucengdes.2013.03.001

Bergant M, Yawny A, Perez Ipiña J. Experimental determination of J-resistance curves of nuclear steam generator tubes. Eng Fract Mech. 2016; 164: 1–18. https://dx.doi.org/10.1016/j.engfracmech.2016.07.008

Bergant M, Yawny A, Perez Ipiña J. Numerical study of the applicability of the g-factor method to J-resistance curve determination of steam generator tubes using non-standard specimens. Eng Fract Mech. 2015; 146: 109–120. https://dx.doi.org/10.1016/j.engfracmech.2015.07.059

Capelle J, Pluvinage G, Modification of failure risk by the use of high strength steels in pipelines, Struct Integr Life. 2013: 13; 23–27 http://divk.inovacionicentar.rs/ivk/ivk13/ivk1301-4.html

Matvienko YG, Gubeljak N. Model for Determination of crack-resistance of the pipes. Patent No. RU 2564696 C, 2015 (in Russian)

Gubeljak N, Likeb A, Matvienko Y. Fracture toughness measurement by using pipe-ring specimens. Proc Mater Sci. 2014; 3: 1934–1940. https://dx.doi.org/10.1016/j.mspro.2014.06.312

Likeb A. Suitability of pipe-ring specimen for determination of fracture toughness. PhD Thesis, University of Maribor, Faculty of Mechanical Engineering, Slovenia, 2014 (in Slovenian)

Likeb A, Gubeljak N, Matvienko Y. Finite element estimation of the plastic ηpl factors for pipe-ring notched bend specimen using the load separation method. Fatigue Fract Eng Mater Struct. 2014; 37: 1319–1329. https://dx.doi.org/10.1111/ffe.12173

Musraty W, Medjo B, Gubeljak N, Likeb A, Cvijović-Alagić I, Sedmak A, Rakin M. Ductile fracture of pipe-ring notched bend specimens - micromechanical analysis. Eng Fract Mech. 2017; 175: 247–261. https://dx.doi.org/10.1016/j.engfracmech.2017.01.022

Damjanović D, Kozak D, Gubeljak N. The influence of residual stresses on fracture behavior of Pipe Ring Notched Bend specimen (PRNB), Eng Fract Mech. 2019; 205: 347–358. https://dx.doi.org/10.1016/j.engfracmech.2018.10.016

Musrati W, Međo B, Gubeljak N, Štefane P, Veljić D, Sedmak A, Rakin M. Fracture assessment of seam and seamless steel pipes by application of the ring-shaped bending specimens. Theor Appl Fract Mech. 2019; 103: paper No. 102302. https://dx.doi.org/10.1016/j.tafmec.2019.102302

Musraty W., Međo B., Gubeljak N., Štefane P., Radosavljević Z., Burzić Z., Rakin M. Seam pipes for process industry - fracture analysis by using ring-shaped specimens. Hem Ind. 2018; 72: 39–46. https://dx.doi.org/10.2298/HEMIND170530014M

EN 10217-1: Welded steel tubes for pressure purposes. Technical delivery conditions Electric welded and submerged arc welded non-alloy steel tubes with specified room temperature properties, 2019.

Inspection certificates No. 31042 and No. 33131/1, Arcelor Mittal Tubular Products Iasi S.A., Romania, 2015.

GOM Precise Industrial 3D Metrology. www.gom.com. Accessed in January, 2023.

Gubeljak N. Application of stereometric measurement on structural integrity. Struct Integr Life. 2006; 6: 65–74. http://divk.inovacionicentar.rs/ivk/ivk06/ivk0601-7.html

Musrati W. Characterisation of damage and fracture of pipeline material using ring-shaped specimens. PhD Thesis, University of Belgrade, Faculty of Technology and Metallurgy, Serbia, 2019.

ASTM E1820: Standard test method for measurement of fracture toughness. 2015.

Displacement gauge system for applications in fracture mechanics. Patent Publication, GKSS Research Center, Geesthacht, Germany, 1991.