Poboljšanje energetskih svojstava lignoceluloznog otpada termohemijskom konverzijom u biočađ Stručni rad

Glavni sadržaj članka

Apstrakt

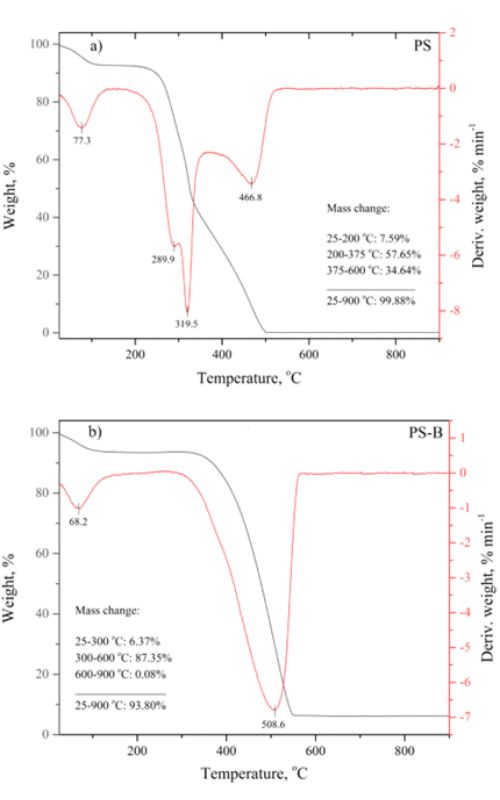

Koštice breskve, otpadna biomasa poreklom iz industrije prerade voća, dostupna u mnogim zemljama širom sveta, predstavlja obnovljivi resurs koji može imati različitu primenu. Prednosti koje se ogledaju u velikom energetskom potencijalu, malom sadržaju pepela, niskoj ceni i širokoj rasprostranjenosti, čine koštice breskve idealnim resursom za proizvodnju energije, ali i za sintezu novih materijala. Iako koštice breskve imaju svojstva koja im omogućavaju da se koriste uz minimalni fizičkio-hemijski tretman, često im je potrebna dodatna modifikacija kako bi se poboljšala njihova svojstva. Jedan on načina poboljšanja energetskih karakteristika otpadne biomase predstavlja termohemijska konverzija materijala u vidu spore pirolize. Ispitivanja prikazana u ovom radu obavljena su sa ciljem obezbeđivanja praktičnog i efikasnog rešenje za revalorizaciju otpadne biomase koja potiče iz industrije prerade voća, putem spore pirolize kojom se vrši konverzija ovog otpada u ugljenični materijal – biočađ. Prikazani rezultati ukazuju na glavna svojstva dobijene biočađi u funkciji njene primene kao čvrstog goriva, istovremeno ih upoređujući sa svojstvima sirove biomase. Termohemijska konverzija polazne lignocelulozne biomase daje stabilni ugljenični material odličnih gorivih karakteristika, veće energetske gustine i boljih mehaničkih svojstava, što rezultuje energetskim svojstvima koja su bolja od uglja. Biočađ poseduje znatno veći energetski potencijal od same biomase, i njegova primena kao biogoriva može redukovati emisiju gasova sa efektom staklene baste, pri čemu se istovremeno smanjuje količina deponovanog otpada ali i povećava udeo energije generisane iz obnovljivih izvora.

Detalji članka

Broj časopisa

Rubrika

Ovaj rad je pod Creative Commons Aуторство-Nekomercijalno-Bez prerade 4.0 Internacionalna licenca.

Kada je rukopis prihvaćen za objavlјivanje, autori prenose autorska prava na izdavača. U slučaju da rukopis ne bude prihvaćen za štampu u časopisu, autori zadržavaju sva prava.

Na izdavača se prenose sledeća prava na rukopis, uklјučujući i dodatne materijale, i sve delove, izvode ili elemente rukopisa:

- pravo da reprodukuje i distribuira rukopis u štampanom obliku, uklјučujući i štampanje na zahtev;

- pravo na štampanje probnih primeraka, reprint i specijalnih izdanja rukopisa;

- pravo da rukopis prevede na druge jezike;

- pravo da rukopis reprodukuje koristeći fotomehanička ili slična sredstva, uklјučujući, ali ne ograničavajući se na fotokopiranje, i pravo da distribuira ove kopije;

- pravo da rukopis reprodukuje i distribuira elektronski ili optički koristeći sve nosioce podataka ili medija za pohranjivanje, a naročito u mašinski čitlјivoj/digitalizovanoj formi na nosačima podataka kao što su hard disk, CD-ROM, DVD, Blu-ray Disc (BD), mini disk, trake sa podacima, i pravo da reprodukuje i distribuira rukopis sa tih prenosnika podataka;

- pravo da sačuva rukopis u bazama podataka, uklјučujući i onlajn baze podataka, kao i pravo prenosa rukopisa u svim tehničkim sistemima i režimima;

- pravo da rukopis učini dostupnim javnosti ili zatvorenim grupama korisnika na osnovu pojedinačnih zahteva za upotrebu na monitoru ili drugim čitačima (uklјučujući i čitače elektonskih knjiga), i u štampanoj formi za korisnike, bilo putem interneta, onlajn servisa, ili putem internih ili eksternih mreža.

Kako citirati

Funding data

-

Ministarstvo Prosvete, Nauke i Tehnološkog Razvoja

Grant numbers 451-03-47/2023-01/200023

Reference

Martín-Lara MA, Pérez A, Vico-Pérez MA, Calero M, Blázquez G. The role of temperature on slow pyrolysis of olive cake for the production of solid fuels and adsorbents. Process Saf Environ Prot. 2019; 121: 209-220. https://doi.org/10.1016/j.psep.2018.10.028

Council of the European Union. Proposal for a Directive of the European Parliament and of the Council on the promotion of the use of energy from renewable sources. 2018; http://data.consilium.europa.eu/doc/document/ST-10308-2018-INIT/en/pdf

Özçimen D, Ersoy-Meriçboyu A. Characterization of biochar and bio-oil samples obtained from carbonization of various biomass materials. Renew Energ. 2010; 35(6): 1319-1324. https://doi.org/10.1016/j.renene.2009.11.042

Kwapinski W, Byrne CMP, Kryachko E, Wolfram P, Adley C, Leahy JJ, Novotny EH, Hayes MHB. Biochar from biomass and waste. Waste Biomass Valorization. 2010; 1: 177–189. https://doi.org/10.1007/s12649-010-9024-8

Obernberger I, Thek G. Physical characterisation and chemical composition of densified biomass fuels with regard to their combustion behaviour. Biomass Bioenergy. 2004; 6: 653-669. https://doi.org/10.1016/j.biombioe.2003.07.006

Huang YF, Cheng PH, Chiueh PT, Lo SL. Leucaena biochar produced by microwave torrefaction: Fuel properties and energy efficiency. Appl Energy. 2017; 204: 1018-1025. https://doi.org/10.1016/j.apenergy.2017.03.007

Channiwala SA, Parikh PP. A unified correlation for estimating HHV of solid, liquid and gaseous fuels. Fuel. 2002; 8: 1051-1063. https://doi.org/10.1016/S0016-2361(01)00131-4

Nachenius RW, van de Wardt TA, Ronsse F, Prins W. Torrefaction of pine in a bench-scale screw conveyor reactor. Biomass Bioenergy. 2015; 79: 96–104. https://doi.org/10.1016/j.biombioe.2015.03.027

Kim D, Lee K, Park KY. Hydrothermal carbonization of anaerobically digested sludge for solid fuel production and energy recovery. Fuel. 2014; 130: 120-125. https://doi.org/10.1016/j.fuel.2014.04.030

Janković B, Manić N, Stojiljković D, Jovanović V. The assessment of spontaneous ignition potential of coals using TGA–DTG technique. Combust Flame. 2020; 211: 32-43. https://doi.org/10.1016/j.combustflame.2019.09.020

Weber K, Heuer S, Quicker P, Li T, Løvås T, Scherer V. An Alternative Approach for the Estimation of Biochar Yields. Energy Fuels. 2018; 32 (9), 9506-9512. https://doi.org/10.1021/acs.energyfuels.8b01825

Lopičić Z, Avdalović J, Milojković J, Antanasković A, Lješević M, Lugonja N, Šoštarić T. Removal of diesel pollution by biochar – Support in water remediation. Hem Ind. 2021; 75(6): 329-338. https://doi.org/10.2298/HEMIND210514029L

Jindo K, Mizumoto H, Sawada Y, Sanchez-Monedero MA, Sonoki T. Physical and chemical characterization of biochars derived from different agricultural residues. Biogeosciences. 2014; 11:6613–6621. https://doi.org/10.5194/bg-11-6613-2014

Abdullah H, Wu H. Biochar as a Fuel: 1. Properties and grindability of biochars produced from the pyrolysis of Mallee wood under slow-heating conditions. Energy Fuels. 2009; 23(8); 4174-4181. https://doi.org/10.1021/ef900494t

Lalak J, Martyniak D, Kasprzycka A, Żurek G, Moroń W, Chmielewska M, Wiącek D, Tys, J. Comparison of selected parameters of biomass and coal. Int Agrophys. 2016; 30(4): 475-482. https://doi.org/10.1515/intag-2016-0021

Dołżyńska M, Obidziński S, Piekut J, Yildiz G. The utilization of plum stones for pellet production and investigation of post-combustion flue gas emissions. Energies. 2020; 13(19): 5107. https://doi.org/10.3390/en13195107

Idris SS, Rahman NA, Ismail K, Alias AB, Rashid ZA, Aris MJ. Investigation on thermochemical behaviour of low rank Malaysian coal, oil palm biomass and their blends during pyrolysis via thermogravimetric analysis (TGA). Bioresour Technol. 2010; 101(12): 4584-4592, https://doi.org/10.1016/j.biortech.2010.01.059

Lopičić Z, Stojanović M, Kaluđerović Radoičić T, Milojković J, Petrović M, Mihajlović M, Kijevčanin M. Optimization of the process of Cu(II) sorption by mechanically treated Prunus persica L. - Contribution to sustainability in food processing industry. J Clean Prod. 2017; 156: 95-105, https://doi.org/10.1016/j.jclepro.2017.04.041

Serapiglia M, Cameron KD, Stipanovic A, Smart LB. Analysis of biomass composition using high-resolution thermogravimetric analysis and percent bark content for the selection of shrub willow bioenergy crop varieties. Bioenergy Res. 2009 2: 1-9. https://doi.org/10.1007/s12155-008-9028-4

Laird DA. The charcoal vision: a win-win-win scenario for simultaneously producing bioenergy, permanently sequestering carbon, while improving soil and water quality. Agron J. 2008; 100: 178-181. https://doi.org/10.2134/agronj2007.0161