Analiza termičkog ponašanja reaktora sa nepokretnim slojem u procesu pirolize Milica Đurđević1, Saša Papuga2 i Aleksandra Kolundžija2 1Mašinski fakultet Banja Luka, Univerzitet u Banjoj Luci, Bosna i Hercegovina 2Tehnološki fakultet Banja Luka, Univerzitet u Banjoj Luci, Bosna i Hercegovina Naučni rad

Glavni sadržaj članka

Apstrakt

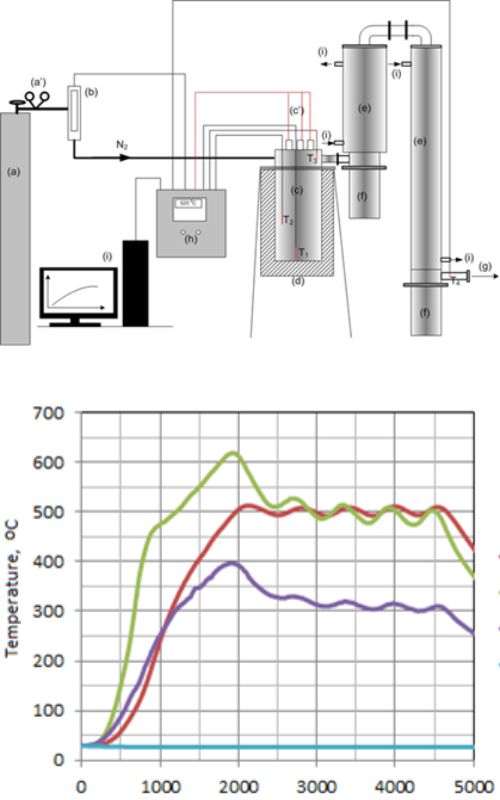

Piroliza je termo-hemijski proces u kojem dolazi do razgradnje organskih jedinjenja. Proces se odvija u inertnoj sredini, a može se primeniti na industrijskom, polu-industrijskom i laboratorijskom nivou. Tokom procesa pirolize, kontroliše se temperatura, međutim, studije i radovi koji se bave pirolizom ne naglašavaju gdje se temperatura mjeri i da li je temperaturno polje ujednačeno. U ovom radu se istražuje termičko ponašanje laboratorijskog reaktora sa nepokretnim slojem, kao i potrošnja energije tokom procesa pirolize. Korišćene su tri varijante polaznih sirovina: mješavina plastičnog otpada (uzorak 1), biomasa (uzorak 2) i mješavina plastike i biomase (uzorak 3). Analiza termičkog ponašanja reaktora ukazuje da se uz pažljivu regulaciju ili kontrolu temperature procesa mogu dobiti zavisnosti koje se mogu koristiti u svrhu registracije termički intenzivnih procesa, slično složenijim analizama odnosno termogravimetrijom (TG) ili derivativnom termogravimetrijom (DTG). Pokazalo se da je moguće promijeniti brzinu zagrijavanja i ukupnu energetsku efikasnost procesa jednostavnim odabirom odgovarajuće sirovinske mješavine.

Detalji članka

Broj časopisa

Rubrika

Ovaj rad je pod Creative Commons Aуторство-Nekomercijalno-Bez prerade 4.0 Internacionalna licenca.

Kada je rukopis prihvaćen za objavlјivanje, autori prenose autorska prava na izdavača. U slučaju da rukopis ne bude prihvaćen za štampu u časopisu, autori zadržavaju sva prava.

Na izdavača se prenose sledeća prava na rukopis, uklјučujući i dodatne materijale, i sve delove, izvode ili elemente rukopisa:

- pravo da reprodukuje i distribuira rukopis u štampanom obliku, uklјučujući i štampanje na zahtev;

- pravo na štampanje probnih primeraka, reprint i specijalnih izdanja rukopisa;

- pravo da rukopis prevede na druge jezike;

- pravo da rukopis reprodukuje koristeći fotomehanička ili slična sredstva, uklјučujući, ali ne ograničavajući se na fotokopiranje, i pravo da distribuira ove kopije;

- pravo da rukopis reprodukuje i distribuira elektronski ili optički koristeći sve nosioce podataka ili medija za pohranjivanje, a naročito u mašinski čitlјivoj/digitalizovanoj formi na nosačima podataka kao što su hard disk, CD-ROM, DVD, Blu-ray Disc (BD), mini disk, trake sa podacima, i pravo da reprodukuje i distribuira rukopis sa tih prenosnika podataka;

- pravo da sačuva rukopis u bazama podataka, uklјučujući i onlajn baze podataka, kao i pravo prenosa rukopisa u svim tehničkim sistemima i režimima;

- pravo da rukopis učini dostupnim javnosti ili zatvorenim grupama korisnika na osnovu pojedinačnih zahteva za upotrebu na monitoru ili drugim čitačima (uklјučujući i čitače elektonskih knjiga), i u štampanoj formi za korisnike, bilo putem interneta, onlajn servisa, ili putem internih ili eksternih mreža.

Kako citirati

Reference

Miandad R, Barakat MA, Aburiazaiza AS, Rehan M, Nizami AS. Catalytic pyrolysis of plastic waste: A review. Process Saf Environ Prot. 2016; 102: 822-38. https://dx.doi.org/10.1016/j.psep.2016.06.022.

Xue Y, Johnston P, Bai X. Effect of catalyst contact mode and gas atmosphere during catalytic pyrolysis of waste plastics. Energy Convers Manag. 2017; 142: 441-51. https://dx.doi.org/10.1016/j.enconman.2017.03.071.

Marcilla A, Gómez-Siurana A, Berenguer D. Study of the influence of the characteristics of different acid solids in the catalytic pyrolysis of different polymers. Appl Catal Gen. 2006; 301(2): 222-31. https://doi.org/10.1016/j.apcata.2005.12.018

Sharma A, Pareek V, Zhang D. Biomass pyrolysis—A review of modelling, process parameters and catalytic studies. Renew Sustain Energy Rev. 2015; 50: 1081-96. https://dx.doi.org/10.1016/j.rser.2015.04.193

Gvero P, Mujanić I, Papuga S, Vasković S, Anatunović R. Review of Synthetic Fuels and New Materials Production Based on Pyrolysis Technologies. In: Pellicer E, Nikolic D, Sort J, Baró M, Zivic F, Grujovic N, et al., editors. Advances in Applications of Industrial Biomaterials [Internet]. Cham: Springer International Publishing; 2017; . 65-85. Available from: http://link.springer.com/10.1007/978-3-319-62767-0_4

Almeida D, Marques M de F. Thermal and catalytic pyrolysis of plastic waste. Polímeros. 2016; 26(1): 44-51. https://dx.doi.org/10.1590/0104-1428.2100

Gvero P, Papuga S, Mujanic I, Vaskovic S. Pyrolysis as a key process in biomass combustion and thermochemical conversion. Therm Sci. 2016; 20(4): 1209-22. https://dx.doi.org/10.2298/TSCI151129154G

Kyaw KT, Hmwe CSS. Effect of various catalysts on fuel oil pyrolysis process of mixed plastic wastes. Int J. Adv. Eng. Technol. 2015; 8(5): 9. https://www.proquest.com/openview/5244b40561785593e77c906355ca14f9/1?pq-origsite=gscholar&cbl=1486350

Babu BV. Biomass pyrolysis: a state-of-the-art review. Biofuels Bioprod Biorefining. 2008; 2(5): 393-414. https://dx.doi.org/10.1002/bbb.92

Armenise S, SyieLuing W, Ramírez-Velásquez JM, Launay F, Wuebben D, Ngadi N, Rams J, Munoz M. Plastic waste recycling via pyrolysis: A bibliometric survey and literature review. J Anal Appl Pyrolysis. 2021; 158: 105265. https://dx.doi.org/10.1016/j.jaap.2021.105265

Kunwar B, Cheng HN, Chandrashekaran SR, Sharma BK. Plastics to fuel: a review. Renew Sustain Energy Rev. 2016; 54: 421-8. https://dx.doi.org/10.1016/j.rser.2015.10.015

Vijayakumar A, Sebastian J. Pyrolysis process to produce fuel from different types of plastic - a review. In: IOP Conf Ser Mater Sci Eng. Kerala State, India, 2018; 396: 012062. https://dx.doi.org/10.1088/1757-899X/396/1/012062

Lopez G, Artetxe M, Amutio M, Bilbao J, Olazar M. Thermochemical routes for the valorization of waste polyolefinic plastics to produce fuels and chemicals. A review. Renew Sustain Energy Rev. 2017 Jun; 73: 346-68. https://dx.doi.org/10.1016/j.rser.2017.01.142

Sharuddin SDA, Abnisa F, Daud WMAW, Aroua MK. Pyrolysis of plastic waste for liquid fuel production as prospective energy resource. In: IOP Conf Ser Mater Sci Eng. Banda Aceh, India, 2018; 334: 012001. https://dx.doi.org/10.1088/1757-899X/334/1/012001

Maqsood T, Dai J, Zhang Y, Guang M, Li B. Pyrolysis of plastic species: A review of resources and products. J Anal Appl Pyrolysis. 2021; 159: 105295. https://dx.doi.org/10.1016/j.jaap.2021.105295

Aguado J, Serrano DP, Escola JM. Fuels from Waste Plastics by Thermal and Catalytic Processes: A Review. Ind Eng Chem Res. 2008; 47(21): 7982-92. https://dx.doi.org/10.1021/ie800393w

Budsaereechai S, Hunt AJ, Ngernyen Y. Catalytic pyrolysis of plastic waste for the production of liquid fuels for engines. RSC Adv. 2019; 9(10): 5844-57. https://dx.doi.org/10.1039/C8RA10058F

Suhartono, Kusumo P, Romli A, Aulia MI, Yanuar EM. Fuel Oil from Municipal Plastic Waste through Pyrolysis with and without Natural Zeolite as Catalysts. Hadiyanto, Maryono, Warsito B, editors. E3S Web Conf. 2018; 73: 01021. https://dx.doi.org/10.1051/e3sconf/20187301021

Pinto F, Costa P, Gulyurtlu I, Cabrita I. Pyrolysis of plastic wastes 2. Effect of catalyst on product yield. J Anal Appl Pyrolysis. 1999; 51: 57-71.

Uthpalani PGI, Premachandra JK, De Silva DSM, Weerasinghe VPA. Pyrolysis as a value added method for plastic waste management: A review on converting LDPE and HDPE waste into fuel [Internet]. In Review; 2022 Jul [cited 2022 Oct 4]. Available from: https://www.researchsquare.com/article/rs-1693804/v1

Kalargaris I, Tian G, Gu S. Combustion, performance and emission analysis of a DI diesel engine using plastic pyrolysis oil. Fuel Process Technol. 2017; 157: 108-15. https://dx.doi.org/10.1016/j.fuproc.2016.11.016

Kalargaris I, Tian G, Gu S. The utilisation of oils produced from plastic waste at different pyrolysis temperatures in a DI diesel engine. Energy. 2017; 131: 179-85. https://dx.doi.org/10.1016/j.energy.2017.05.024

Kalargaris I, Tian G, Gu S. Investigation on the long-term effects of plastic pyrolysis oil usage in a diesel engine. Energy Procedia. 2017; 142: 49-54. https://dx.doi.org/10.1016/j.egypro.2017.12.009

Kalargaris I, Tian G, Gu S. Experimental characterisation of a diesel engine running on polypropylene oils produced at different pyrolysis temperatures. Fuel. 2018; 211: 797-803. https://dx.doi.org/10.1016/j.fuel.2017.09.101

Kremer I, Tomić T, Katančić Z, Erceg M, Papuga S, Vuković JP, Schneider DR. Catalytic pyrolysis of mechanically non-recyclable waste plastics mixture: Kinetics and pyrolysis in laboratory-scale reactor. J Environ Manage. 2021; 296: 113145. https://dx.doi.org/10.1016/j.jenvman.2021.113145

Kremer I, Tomić T, Katančić Z, Hrnjak-Murgić Z, Erceg M, Schneider DR. Catalytic decomposition and kinetic study of mixed plastic waste. Clean Technol Environ Policy. 2021; 23(3): 811-27. https://dx.doi.org/10.1007/s10098-020-01930-y

Kremer I, Tomić T, Katančić Z, Hrnjak-Murgić Z, Erceg M, Vecchio Ciprioti S, Schneider DR. Effect of Zeolite Catalyst on the Pyrolysis Kinetics of Multi-Layered Plastic Food Packaging. Symmetry. 2022; 14(7): 1362. https://dx.doi.org/10.3390/sym14071362

Papuga S, Gvero P, Vukic L. Temperature and time influence on the waste plastics pyrolysis in the fixed bed reactor. Therm Sci. 2016; 20(2): 731-41. https://dx.doi.org/10.2298/TSCI141113154P

Dewangga PB, Rochmadi, Purnomo CW. Pyrolysis of polystyrene plastic waste using bentonite catalyst.In: IOP Conf Ser Earth Environ Sci. Bogor, Indonesia, 2019; 399(1): 012110. https://dx.doi.org/10.1088/1755-1315/399/1/012110

Papuga S, Djurdjevic M, Ciccioli A, Vecchio Ciprioti S. Catalytic Pyrolysis of Plastic Waste and Molecular Symmetry Effects: A Review. Symmetry. 2022; 15(1): 38. https://dx.doi.org/10.3390/sym15010038

Fadillah G, Fatimah I, Sahroni I, Musawwa MM, Mahlia TMI, Muraza O. Recent Progress in Low-Cost Catalysts for Pyrolysis of Plastic Waste to Fuels. Catalysts. 2021; 11(7): 837. https://dx.doi.org/10.3390/catal11070837

Garcia-Nunez JA, Pelaez-Samaniego MR, Garcia-Perez ME, Fonts I, Abrego J, Westerhof RJM, et al. Historical Developments of Pyrolysis Reactors: A Review. Energy Fuels. 2017; 31(6): 5751-75. https://dx.doi.org/10.1021/acs.energyfuels.7b00641

Gholizadeh M, Li C, Zhang S, Wang Y, Niu S, Li Y, et al. Progress of the development of reactors for pyrolysis of municipal waste. Sustain Energy Fuels. 2020; 4(12): 5885-915. https://dx.doi.org/10.1039/D0SE01122C

Kabir G, Mohd Din AT, Hameed BH. Pyrolysis of oil palm mesocarp fiber and palm frond in a slow-heating fixed-bed reactor: A comparative study. Bioresour Technol. 2017; 241: 563-72. https://dx.doi.org/10.1016/j.biortech.2017.05.180

Wang Z, Cao J, Wang J. Pyrolytic characteristics of pine wood in a slowly heating and gas sweeping fixed-bed reactor. J Anal Appl Pyrolysis. 2009; 84(2): 179-84. https://dx.doi.org/10.1016/j.jaap.2009.02.001

Kremer I, Tomić T, Katančić Z, Erceg M, Papuga S, Parlov Vuković J, Schneider DR. Catalytic pyrolysis and kinetic study of real-world waste plastics: multi-layered and mixed resin types of plastics. Clean Technol Environ Policy. 2022; 24(2): 677-93. https://dx.doi.org/10.1007/s10098-021-02196-8

Selpiana, Aprianti T, Rayosa I, Fuspitasarie D. Expanded polystyrene and multilayer plastic waste conversion into liquid fuel by the pyrolysis process. In Surakarta, Indonesia; 2018 [cited 2022 Oct 7]. p. 020151. Available from: http://aip.scitation.org/doi/abs/10.1063/1.5054555

Bridgwater AV, Meier D, Radlein D. An overview of fast pyrolysis of biomass. Org Geochem. 1999; 30(12): 1479-93. https://dx.doi.org/10.1016/S0146-6380(99)00120-5

Lee CG, Cho YJ, Song PS, Kang Y, Kim JS, Choi MJ. Effects of temperature distribution on the catalytic pyrolysis of polystyrene waste in a swirling fluidized-bed reactor. Catal Today. 2003; 79-80: 453-64. https://dx.doi.org/10.1016/S0920-5861(03)00060-9

Pandey U, Stormyr JA, Hassani A, Jaiswal R, Haugen HH, Moldestad BME. Pyrolysis of plastic waste to environmentally friendly products. In 2020 [cited 2022 Aug 15]. p. 61-74. Available from: http://library.witpress.com/viewpaper.asp?pcode=EPM20-007-1

Hartulistiyoso E, Sigiro FAPAG, Yulianto M. Temperature Distribution of the Plastics Pyrolysis Process to Produce Fuel at 450oC. Procedia Environ Sci. 2015; 28: 234-41. https://dx.doi.org/10.1016/j.proenv.2015.07.030

Bockhorn H, Hornung A, Hornung U, Jakobströer P. Modelling of isothermal and dynamic pyrolysis of plastics considering non-homogeneous temperature distribution and detailed degradation mechanism. J Anal Appl Pyrolysis. 1999; 49(1-2): 53-74. https://dx.doi.org/10.1016/S0165-2370(98)00130-2

Chen D, Zheng Y, Zhu X. In-depth investigation on the pyrolysis kinetics of raw biomass. Part I: Kinetic analysis for the drying and devolatilization stages. Bioresour Technol. 2013; 131: 40-6. https://dx.doi.org/10.1016/j.biortech.2012.12.136

Swamardika IBA, Winaya INS, Hartati RS. Utilization plastic waste using pyrolysis fixed bed. In: IOP Conf. Ser. Mater Sci Eng. Bali, Indonesia, 2019; 9. https://dx.doi.org/10.1088/1757-899X/539/1/012021

Xingzhong Y. Converting Waste Plastics into Liquid Fuel by Pyrolysis: Developments in China. In: Scheirs J, Kaminsky W, editors. Feedstock Recycling and Pyrolysis of Waste Plastics [Internet]. Chichester, UK: John Wiley & Sons, Ltd; 2006 [cited 2022 Aug 15]. p. 729-55. Available from: https://onlinelibrary.wiley.com/doi/10.1002/0470021543.ch28

Gao F. Pyrolysis of Waste Plastics into Fuels. Dissertation, 2010; Available from: https://ir.canterbury.ac.nz/handle/10092/4303. https://dx.doi.org/10.26021/3251

Abdullah NA, Novianti A, Hakim II, Putra N, Koestoer RA. Influence of temperature on conversion of plastics waste (polystyrene) to liquid oil using pyrolysis process. IOP Conf Ser Earth Environ Sci. 2018; 105: 012033. https://dx.doi.org/10.1088/1755-1315/105/1/012033

Job S, Mativenga P, Shuaib NA, Oliveux G, Leeke G, Pickering S. Composites Recycling - Where are we now? Composites UK. 2016. https://compositesuk.co.uk/system/files/documents/Recycling%20Report%202016%20-%20Light%20Background.pdf

van Oudheusden AA. Recycling of composite materials. :68. Student thesis. http://resolver.tudelft.nl/uuid:0749ed5c-7aeb-4275-abee-0f904a08ea4d