Ispitivanje opasnog otpada - Studija slučaja karakterizacije prašine iz elektrolučne peći Stručni rad

Glavni sadržaj članka

Apstrakt

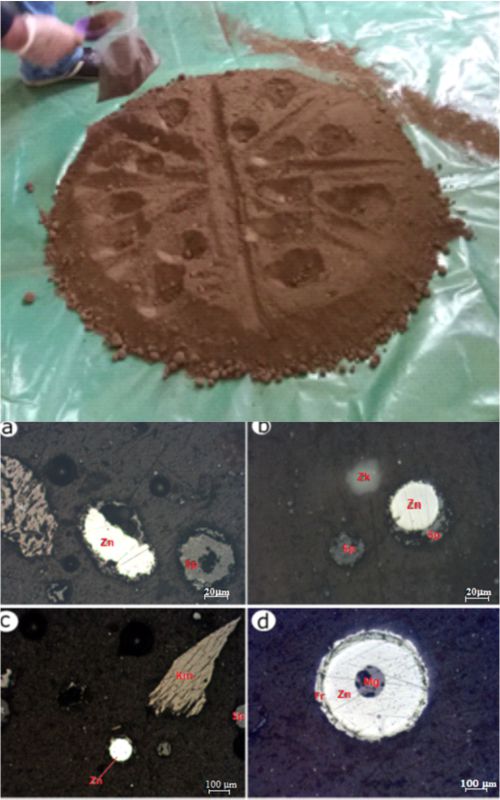

Kao međuprodukt procesa dobijanja čelika topljenjem sekundarnih sirovina na bazi gvožđa u elektrolučnoj peći, nastaje prašina. Ova prašina iz elektrolučne peći ima značajan sadržaj Zn i Fe, kao i Pb, Cd, Ca, Mg, Cr, Mn, Si, Ni, Cu, F, Cl i dr. elemenata i smatra se opasnim industrijskim čvrstim otpadom obzirom da u svom sastavu sadrži teške metale. U cilju zaštite životne sredine i javnog zdravlja od negativnog uticaja ove vrste opasnog otpada, neophodno je, čak i obavezno, sprovesti tretman otpada u skladu sa zakonodavstvom zemlje u kojoj se nalazi. Pre nego što se primeni bilo koji tretman prerade prašine iz elektrolučne peći, potrebno je izvršiti njenu detaljnu karakterizaciju. U ovom radu, izvršena je sledeća karakterizacija uzoraka prašine iz elektrolučne peći iz postrojenja u Republici Srbiji: fizička, hemijska, kao i mineraloška karakterizacija, određen je granulometrijski sastav, a određena je i procena uticaja prašine na životnu sredinu i zdravlje ljudi (testovi toksičnosti i lužljivosti). Rezultati istraživanja ove vrste opasnog otpada pokazali su da je sadržaj Zn u prašini iz elektrolučne peći iznosio od 32 mas.% do 35 mas.% i da su glavne mineraloške faze prašine cinkit, franklinit, magnetit i magnezioferit. Granulometrijska analiza je pokazala da se 80 % uzorka sastoji od čestica veličine manje od 26 µm. Što se tiče rezultata testa lužljivosti, prašina je okarakterisana kao opasan otpad zbog povećanog sadržaja hlorida, dok je testom toksičnosti utvrđeno da ispitivana prašina pokazuje toksična svojstva zbog povećanog sadržaja Zn, Cd i Pb.

Detalji članka

Broj časopisa

Rubrika

Ovaj rad je pod Creative Commons Aуторство-Nekomercijalno-Bez prerade 4.0 Internacionalna licenca.

Kada je rukopis prihvaćen za objavlјivanje, autori prenose autorska prava na izdavača. U slučaju da rukopis ne bude prihvaćen za štampu u časopisu, autori zadržavaju sva prava.

Na izdavača se prenose sledeća prava na rukopis, uklјučujući i dodatne materijale, i sve delove, izvode ili elemente rukopisa:

- pravo da reprodukuje i distribuira rukopis u štampanom obliku, uklјučujući i štampanje na zahtev;

- pravo na štampanje probnih primeraka, reprint i specijalnih izdanja rukopisa;

- pravo da rukopis prevede na druge jezike;

- pravo da rukopis reprodukuje koristeći fotomehanička ili slična sredstva, uklјučujući, ali ne ograničavajući se na fotokopiranje, i pravo da distribuira ove kopije;

- pravo da rukopis reprodukuje i distribuira elektronski ili optički koristeći sve nosioce podataka ili medija za pohranjivanje, a naročito u mašinski čitlјivoj/digitalizovanoj formi na nosačima podataka kao što su hard disk, CD-ROM, DVD, Blu-ray Disc (BD), mini disk, trake sa podacima, i pravo da reprodukuje i distribuira rukopis sa tih prenosnika podataka;

- pravo da sačuva rukopis u bazama podataka, uklјučujući i onlajn baze podataka, kao i pravo prenosa rukopisa u svim tehničkim sistemima i režimima;

- pravo da rukopis učini dostupnim javnosti ili zatvorenim grupama korisnika na osnovu pojedinačnih zahteva za upotrebu na monitoru ili drugim čitačima (uklјučujući i čitače elektonskih knjiga), i u štampanoj formi za korisnike, bilo putem interneta, onlajn servisa, ili putem internih ili eksternih mreža.

Kako citirati

Funding data

-

Ministarstvo Prosvete, Nauke i Tehnološkog Razvoja

Grant numbers 451-03-68/2022-14/200052;451-03-68/2022-14/200131

Reference

Siame MC, Kaoma J, Hlabangana N, Danha G. An Attainable Region Approach for the Recovery of Iron and Zinc from Electric Arc Furnace Dust. S. Afr. J. Chem. Eng. 2019; 27: 35–42 https://doi.org/10.1016/j.sajce.2018.12.002.

Wu CC, Chang FC, Chen WS, Tsai MS, Wang YN. Reduction Behavior of Zinc Ferrite in EAF-Dust Recycling with CO Gas as a Reducing Agent. J. Environ. Manage. 2014; 143: 208-213 https://doi.org/10.1016/j.jenvman.2014.04.005.

Wang J, Zhang Y, Cui K, Fu T, Gao J, Hussain S, AlGarni TS. Pyrometallurgical Recovery of Zinc and Valuable Metals from Electric Arc Furnace Dust - A Review. J. Cleaner Prod. 2021; 298: 126788 https://doi.org/10.1016/j.jclepro.2021.126788.

Kukurugya F, Vindt T, Havlík T. Behavior of Zinc, Iron and Calcium from Electric Arc Furnace (EAF) Dust in Hydrometallurgical Processing in Sulfuric Acid Solutions: Thermodynamic and Kinetic Aspects. Hydrometall. 2015; 154: 20–32 https://doi.org/10.1016/j.hydromet.2015.03.008.

Silvaa VS, Silvaa JS, Costaa BdS, Labesb C, Oliveira RMPB. Preparation of Glaze Using Electric-Arc Furnace Dust as Raw Material. J. Mater. Res. Technol. 2019; 8(6): 5504–5514 https://doi.org/10.1016/j.jmrt.2019.09.018.

Hazaveh PK, Karimia S, Rashchia F, Sheibania S. Purification of the Leaching Solution of Recycling Zinc from the Hazardous Electric Arc Furnace Dust Through an As-Bearing Jarosite. Ecotoxicol. Environ. Saf. 2020; 202: 110893 https://doi.org/10.1016/j.ecoenv.2020.110893.

Čerňan M, Müller Z, Tlustý J, Valouch V. An Improved SVC Control for Electric Arc Furnace Voltage Flicker Mitigation. Int. J. Electr. Power Energy Syst. 2021; 129: 106831 https://doi.org/10.1016/j.ijepes.2021.106831.

Bruckard WJ, Davey KJ, Rodopoulos T, Woodcock JT, Italiano J. Water Leaching and Magnetic Separation for Decreasing the Chloride Level and Upgrading the Zinc Content of EAF Steelmaking Baghouse Dusts. Int. J. Miner. Process. 2005; 75: 1 – 20 https://doi.org/10.1016/j.minpro.2004.04.007.

Trifunović V, Avramović Lj, Jonović R, Milić S, Đorđievski S, Jonović M. Hydrometallurgical Treatment of EAF Dust in aim of Zinc Separation, Proceedings/52nd International October Conference on Mining and Metallurgy ‐ IOC 2021. In: Proceedings of The 52nd International October Conference on Mining and Metallurgy, Bor, Serbia, 2021, pp. 209-212 ISBN:978-86-6305-119-5.

Halli P, Hamuyuni J, Revitzer H, Lundström M. Selection of Leaching Media for Metal Dissolution from Electric Arc Furnace Dust. J. Cleaner Prod. 2017; 164: 265-276 https://doi.org/10.1016/j.jclepro.2017.06.212.

Havlik T, Turzakova M, Stopic S, Friedrich B, Atmospheric Leaching of EAF Dust With Diluted Sulphuric Acid, Hydrometall. 2005; 77: 41–50 https://doi.org/10.1016/j.hydromet.2004.10.008.

Keglevich de Buzin PJW, Heck NC, Vilela ACF. EAF dust: An Overview on the Influences of Physical, Chemical and Mineral Features in its Recycling and Waste Incorporation Routes. J. Mater. Res. Technol. 2017; 6(2): 194–202 https://doi.org/10.1016/j.jmrt.2016.10.002.

Halli P, Hamuyuni J, Leikola M, Lundström M. Developing a Sustainable Solution for Recycling Electric Arc Furnace Dust via Organic Acid Leaching. Miner. Eng. 2018; 124: 1–9 https://doi.org/10.1016/j.mineng.2018.05.011.

Omran M, Fabritius T. Effect of Steelmaking Dust Characteristics on Suitable Recycling Process Determining: Ferrochrome Converter (CRC) and Electric Arc Furnace (EAF) Dusts, Powder Technol. 2017; 308: 47–60 https://doi.org/10.1016/j.powtec.2016.11.049.

Al-harahsheh M, Al-Nu’airat J, Al-Otoom A, Al-hammouri I, Al-jabali H, Al-zoubi M, Abu Al’asal S. Treatments of Electric Arc Furnace Dust and Halogenated Plastic Wastes: A Review. J. Environ. Chem. Eng. 2019; 7: 102856 https://doi.org/10.1016/j.jece.2018.102856.

Omran M, Fabritius T. Effect of Steelmaking Dust Characteristics on Suitable Recycling Process Determining: Ferrochrome Converter (CRC) and Electric Arc Furnace (EAF) Dusts, Powder Technol. 2017; 308: 47–60 https://doi.org/10.1016/j.powtec.2016.11.049.

Ruiz O, Clemente C, Alonso M. Alguacil FJ. Recycling of an Electric Arc Furnace Flue Dust to Obtain High Grade Zno. J. Hazard. Mater. 2007; 141: 33–36 https://doi.org/10.1016/j.jhazmat.2006.06.079.

Pickles CA, Marzoughi O. Thermodynamic Analysis of Metal Speciation During the Chlorosulphation of Electric Arc Furnace Dust. Miner. Eng. 2019; 140: 105874 https://doi.org/10.1016/j.mineng.2019.105874.

Khattab RM, El-Sayed Seleman MM, Zawrah MF. Assessment of Electric Arc Furnace Dust: Powder Characterization and its Sinterability as Ceramic Product. Ceram. Int. 2017; 43: 12939–12947 https://doi.org/10.1016/j.ceramint.2017.06.192.

Alencastro de Araújo J, Schalch V, Recycling of Electric Arc Furnace (EAF) Dust for Use in Steel Making Process, J. Mater. Res. Technol. 2014; 3(3): 274–279 https://doi.org/10.1016/j.jmrt.2014.06.003.

Li YC, Zhuo SN, Peng B, Min XB, Liu H, Ke Y. Comprehensive Recycling of Zinc and Iron From Smelting Waste Containing Zinc Ferrite by Oriented Transformation with SO2. J. Cleaner Prod. 2020; 263: 121468 https://doi.org/10.1016/j.jclepro.2020.121468.

Environmental Protection Agency, Land Disposal Restrictions for Electric Arc Furnace Dust (K061) - Federal Register Notice, Vol. 56 No. 160, August 19, 1991 p 41164.

Norma Brasileira, ABNT 10004:2004, Solid waste Classification, 2004.

Commission of the European Communities, Guidance on classification of waste according toEWC-Stat categories, Supplement to the Manual for the Implementation of the Regulation (EC) No 2150/2002 on Waste Statistics, version 2, December 2010.

Ledesma EF, Lozano-Lunar A, Ayuso J, Galvín AP, Fernández JM, Jiménez JR. The Role of pH on Leaching of Heavy Metals and Chlorides from Electric Arc Furnace Dust in Cement-Based Mortars. Constr. Build. Mater. 2018; 183: 365–375 https://doi.org/10.1016/j.conbuildmat.2018.06.175.

Ng KS, Head I, Premier GC, Scott K, Yu E, Lloyd J, Sadhukhan J. A Multilevel Sustainability Analysis of Zinc Recovery from Wastes. Resour. Conserv. Recycl. 2016; 113: 88–105 https://doi.org/10.1016/j.resconrec.2016.05.013.

Pickles CA. Thermodynamic Modelling of the Multiphase Pyrometallurgical Processing of Electric Arc Furnace Dust. Miner. Eng. 2009; 22: 977–985 https://doi.org/10.1016/j.mineng.2009.03.007.

Miki T, Chairaksa-Fujimoto R, Maruyama K, Nagasaka T. Hydrometallurgical Extraction of Zinc from CaO Treated EAF Dust in Ammonium Chloride Solution. J. Hazard. Mater. 2016; 302: 90–96 https://doi.org/10.1016/j.jhazmat.2015.09.020.

Rudnik E. Investigation of Industrial Waste Materials for Hydrometallurgical Recovery of Zinc. Miner. Eng. 2019; 139: 105871 https://doi.org/10.1016/j.mineng.2019.105871.