Study on thermal comfort behaviour of seams made of micro-denier polyester sewing thread for high active sportswear Original scientific paper

Main Article Content

Abstract

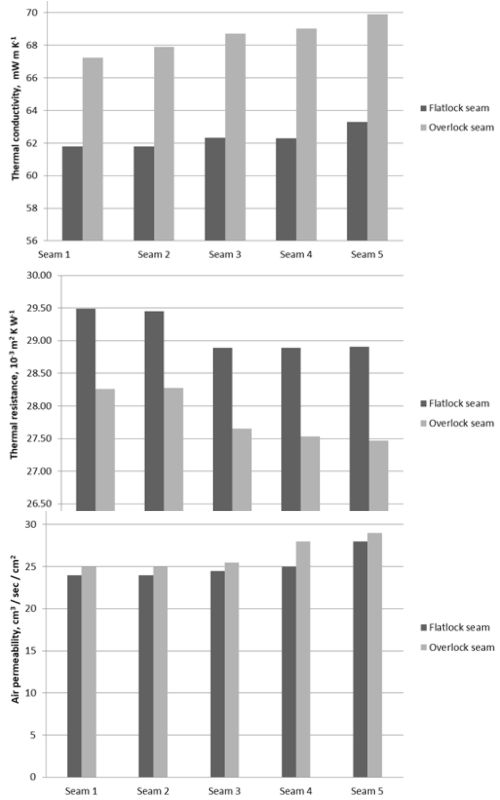

This work aims to investigate the thermal comfort behaviour of polyester seamed fabric regarding the change in sewing thread filaments fineness for two different seam classes: seam 514 and seam 607. Five seamed fabric samples were constructed with using micro-denier polyester filament of 16.66 tex made of five different filament numbers (38, 48, 108, 144 and 288). It was noticed that the seam thermal properties, air and water vapour permeability, and wicking can be improved if the seam is constructed with using the micro-denier polyester sewing thread. It was also found that the investigated properties increase with the increase in the sewing thread filament fineness on the seam line. The statistical results have also shown that the sewing thread filament fineness is significantly affecting thermal behaviour of the seamed fabric.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

References

Rameshkumar C, Rengasamy RS, Anbumani N. Studies on polyester/waste silk core-spun yarns and fabrics. J Ind Text. 2009; 38(3): 191-203. https://doi.org/10.1177/1528083708091065

Bartels VT, Physiological comfort of sportswear. In: Shishoo R, ed. Textiles in Sport. Cambridge, England: Woodhead Publishing; 2005: 176-203.

Ho C, Fan J, Newton E, Au R. Effects of athletic T-shirt designs on thermal comfort. Fibre Polym. 2008; 9(4): 503-508. https://link.springer.com/article/10.1007/s12221-008-0080-7

Beaudette E, Park H. Impact of seam types on thermal properties of athletic bodywear. Text Res J. 2017; 87(9): 1052-1059. https://doi.org/10.1177/0040517516648506

Sandip V, Narsingh R. Microfibres, microfilaments & their applications. Autex Res J. 2007; 7(3): 148-158. http://www.autexrj.org/No3-2007/0240.pdf

Havenith G, Heus R, Lotens WA. Resultant clothing insulation: a function of body movement, posture, wind, clothing fit and ensemble thickness. Ergonomics 1990; 33(1): 67-84. https://doi.org/10.1080/00140139008927094

Srinivasan, J. Engineering finer and softer textile yarns. Alagirusamy R, Das A (eds.) Technical Textile Yarns. USA: Woodhead Publishing, 2010: 185.

Jhanji Y, Gupta D, Kothari VK. Thermo-physiological properties of polyester–cotton plated fabrics in relation to fibre linear density and yarn type, Fashion and Textiles, 2015; 2(1): 1-14 https://doi.10.1186/s40691-015-0041-x

Wang N, Zha A, Wang J. Study on the wicking property of polyester filament yarns. Fibre Polym. 2008; 9(1): 97-100 https://link.springer.com/article/10.1007/s12221-008-0016-2

Varshney RK, Kothari VK, Dhamija S. A study on thermophysiological comfort properties of fabrics in relation to constituent fibre fineness and cross-sectional shapes. J Text Inst. 2010; 101(6): 495-505 https://doi.org/10.1080/00405000802542184

Raj S, Sreenivasan S. Total wear comfort index as an objective parameter for characterization of overall wearability of cotton fabrics. J Eng Fiber Fabric. 2009; 4(4): 29-41 https://doi.10.1186/s40691-015-0041-x