Development of an analytical model for copper heap leaching from secondary sulfides in chloride media in an industrial environment Technical paper

Main Article Content

Abstract

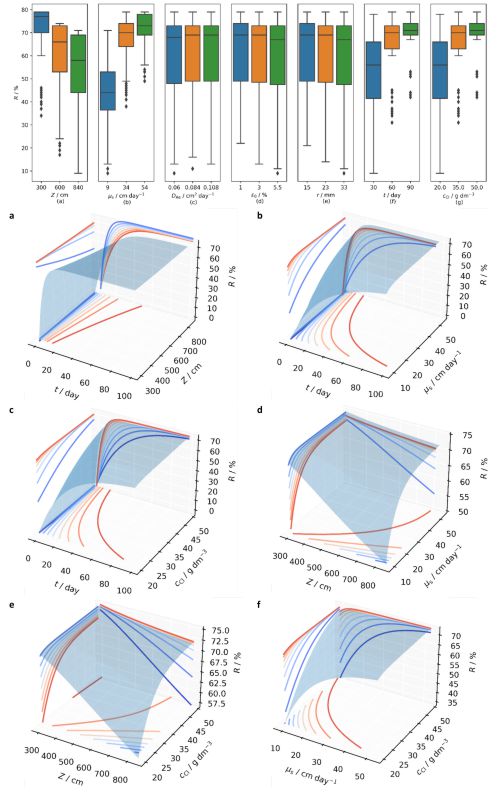

In multivariate analysis, a predictive model is a mathematical/statistical model that relates a set of independent variables to dependent or response variable(s). This work presents a descriptive model that explains copper recovery from secondary sulfide minerals (chalcocite) taking into account the effects of time, heap height, superficial velocity of leaching flow, chloride concentration, particle size, porosity, and effective diffusivity of the solute within particle pores. Copper recovery is then modelled by a system of first-order differential equations. The results indicated that the heap height and superficial velocity of leaching flow are the most critical independent variables while the others are less influential under operational conditions applied. In the present study representative adjustment parameters are obtained, so that the model could be used to explore copper recovery in chloride media as a part of the extended value chain of the copper sulfides processing.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

Funding data

-

Fondo de Financiamiento de Centros de Investigación en Áreas Prioritarias

Grant numbers ANID/FONDAP/15110017

References

Flanagan DM. Copper. In Mineral Commodity Summaries 2021. Reston, VA, USA: U.S. Geological Survey; 2021; 52–3. ISBN 9781411343986.

Villela D, Kutscher C, Castillo E. Sulfuros primarios: desafíos y oportunidades. Comisión Chilena del Cobre (COCHILCO). Santiago, Chile: 2017.

ICSG. Copper: Preliminary Data for January 2020. International Copper Study Group (ICSG): Lisbon, Portugal: 2020.

Pérez K, Toro N, Gálvez E, Robles P, Wilson R, Navarra A. Environmental, economic and technological factors affecting Chilean copper smelters – A critical review. Journal of Materials Research and Technology 2021; 15: 213–25. https: //doi.org/10.1016/j.jmrt.2021.08.007

Navarra A, Wilson R, Parra R, Toro N, Ross A, Nave JC, Mackey PJ. Quantitative methods to support data acquisition modernization within copper smelters. Processes 2020; 8(11): 1–22. https: //doi.org/10.3390/pr8111478

Lazo A, Lazo P, Urtubia A, Lobos MG, Gutiérrez C, Hansen HK. Copper Analysis by Two Different Procedures of Sequential Extraction after Electrodialytic Remediation of Mine Tailings. International Journal of Environmental Research and Public Health 2019; 16(20): 3957. https: //doi.org/10.3390/ijerph16203957

Rodríguez F, Moraga C, Castillo J, Gálvez E, Robles P, Toro N. Submarine tailings in chile—a review. Metals (Basel) 2021; 11(5): 1–17. https: //doi.org/10.3390/met11050780

Toro N, Rodríguez F, Rojas A, Robles P, Ghorbani Y. Leaching manganese nodules with iron-reducing agents – A critical review. Minerals Engineering 2021; 163: 106748. https: //doi.org/10.1016/J.MINENG.2020.106748

Dijkstra R. Economical abatement of high-strength SO2 off-gas from a smelter. J South Afr. Inst. Min. Metall. 2017; 117(11): 1003–7. https: //doi.org/10.17159/2411-9717/2017/v117n11a2

Daibova EB, Lushchaeva I v, Sachkov VI, Karakchieva NI, Orlov V v, Medvedev RO, Nefedov RA, Shplis ON, Sodnam NI. Bioleaching of Au-Containing Ore Slates and Pyrite Wastes. Minerals 2019; 9(10): 1–11. https: //doi.org/10.3390/min9100643

Conić V, Stanković S, Marković B, Božić D, Stojanović J, Sokić M. Investigation of the optimal technology for copper leaching from old flotation tailings of the copper mine bor (Serbia). Metallurgical and Materials Engineering 2020; 26(2): 209–22. https: //doi.org/10.30544/514

Casas JM, Martinez J, Moreno L, Vargas T. Bioleaching model of a copper-sulfide ore bed in heap and dump configurations. Metallurgical and Materials Transactions B: Process Metallurgy and Materials Processing Science 1998; 29(4): 899–909. https: //doi.org/10.1007/s11663-998-0149-0

Behrad Vakylabad A, Nazari S, Darezereshki E. Bioleaching of copper from chalcopyrite ore at higher NaCl concentrations. Minerals Engineering 2022; 175: 107281. https: //doi.org/10.1016/J.MINENG.2021.107281

Ghorbani Y, Franzidis J-P, Petersen J. Heap leaching technology – current state, innovations and future directions: A review. Mineral Processing and Extractive Metallurgy Review 2015: 08827508.2015.1115990. https: //doi.org/10.1080/08827508.2015.1115990

Kevin Pérez , Norman Toro, Eduardo Campos AN and MHR. Extraction of Mn from Black Copper Using Iron Acid Medium. Metals (Basel) 2019; 9(10): 1–10. https: //doi.org/https: //doi.org/10.3390/met9101112

Hernández PC, Taboada ME, Herreros OO, Graber TA, Ghorbani Y. Leaching of chalcopyrite in acidified nitrate using seawater-based media. Minerals 2018; 8(6). https: //doi.org/10.3390/min8060238

Toro N, Ghorbani Y, Turan MD, Robles P, Gálvez E. Gangues and Clays Minerals as Rate-Limiting Factors in Copper Heap Leaching: A Review. Metals 2021, Vol 11, Page 1539 2021; 11(10): 1539. https: //doi.org/10.3390/MET11101539

Cerda CP, Taboada ME, Jamett NE, Ghorbani Y, Hernández PC. Effect of pretreatment on leaching primary copper sulfide in acid-chloride media. Minerals 2018; 8(1): 1–14. https: //doi.org/10.3390/min8010001

Pradhan N, Nathsarma KC, Srinivasa Rao K, Sukla LB, Mishra BK. Heap bioleaching of chalcopyrite: A review. Minerals Engineering 2008; 21(5): 355–65. https: //doi.org/10.1016/j.mineng.2007.10.018

Castillo J, Sepúlveda R, Araya G, Guzmán D, Toro N, Pérez K, Rodríguez M, Navarra A. Leaching of white metal in a NaCl-H2SO4 system under environmental conditions. Minerals 2019; 9(5). https: //doi.org/10.3390/min9050319

Velásquez-Yévenes L. The kinetics of the dissolution of chalcopyrite in chloride media: PhD Thesis, Murdoch University, Australia. 2009.

Velásquez-Yévenes L, Nicol M, Miki H. The dissolution of chalcopyrite in chloride solutions Part 1. The effect of solution potential. Hydrometallurgy 2010; 103(1–4): 108–13. https: //doi.org/10.1016/j.hydromet.2010.03.001

Nicol M, Miki H, Velásquez-Yévenes L. The dissolution of chalcopyrite in chloride solutions Part 3. Mechanisms. Hydrometallurgy 2010; 103(1–4): 86–95. https: //doi.org/10.1016/j.hydromet.2010.03.003

Torres CM, Ghorbani Y, Hernández PC, Justel FJ, Aravena MI, Herreros OO. Cupric and chloride ions: Leaching of chalcopyrite concentrate with low chloride concentration media. Minerals 2019; 9(10). https: //doi.org/10.3390/min9100639

Nicol M, Basson P. The anodic behaviour of covellite in chloride solutions. Hydrometallurgy 2017; 172(June): 60–8. https: //doi.org/10.1016/j.hydromet.2017.06.018

Pérez K, Toro N, Saldaña M, Salinas-Rodríguez E, Robles P, Torres D, Jeldres RI. Statistical Study for Leaching of Covellite in a Chloride Media. Metals (Basel) 2020; 10(4): 477. https: //doi.org/10.3390/met10040477

Toro N, Moraga C, Torres D, Saldaña M, Pérez K, Gálvez E. Leaching Chalcocite in Chloride Media—A Review. Minerals 2021; 11(11): 1197. https: //doi.org/10.3390/min11111197

Cisternas LA, Gálvez ED. The use of seawater in mining. Mineral Processing and Extractive Metallurgy Review 2018; 39(1): 18–33. https: //doi.org/10.1080/08827508.2017.1389729

Bogdanović GD, Petrović S, Sokić M, Antonijević MM. Chalcopyrite leaching in acid media: a review. Metallurgical and Materials Engineering 2020; 26(2): 177–98. https: //doi.org/10.30544/526

Yévenes LV, Miki H, Nicol M. The dissolution of chalcopyrite in chloride solutions: Part 2: Effect of various parameters on the rate. Hydrometallurgy 2010; 103(1–4): 80–5. https: //doi.org/10.1016/j.hydromet.2010.03.004

Dimitrijević M, Urošević D, Milić S, Sokić M, Marković R. Dissolution of copper from smelting slag by leaching in chloride media. Journal of Mining and Metallurgy, Section B: Metallurgy 2017; 53(3): 407–12. https: //doi.org/10.2298/JMMB170425016D

Petronijević N, Stanković S, Radovanović D, Sokić M, Marković B, Stopić SR, Kamberović Ž. Application of the Flotation Tailings as an Alternative Material for an Acid Mine Drainage Remediation: A Case Study of the Extremely Acidic Lake Robule (Serbia). Metals 2020, Vol 10, Page 16 2019; 10(1): 16. https: //doi.org/10.3390/MET10010016

Sokić M, Marković B, Stanković S, Kamberović Ž, Štrbac N, Manojlović V, Petronijević N. Kinetics of Chalcopyrite Leaching by Hydrogen Peroxide in Sulfuric Acid. Metals 2019, Vol 9, Page 1173 2019; 9(11): 1173. https: //doi.org/10.3390/MET9111173

Córdoba EM, Muñoz JA, Blázquez ML, González F, Ballester A. Leaching of chalcopyrite with ferric ion. Part I: General aspects. Hydrometallurgy 2008; 93(3–4): 81–7. https: //doi.org/10.1016/j.hydromet.2008.04.015

Molinos-Senante M, Donoso G. Water scarcity and affordability in urban water pricing: A case study of Chile. Utilities Policy 2016; 43: 107–16. https: //doi.org/10.1016/J.JUP.2016.04.014

Saleth RM, Dinar A. Institutional changes in global water sector: trends, patterns, and implications. Water Policy 2000; 2(3): 175–99. https: //doi.org/10.1016/S1366-7017(00)00007-6

Ministerio del Medio Ambiente. Informe del Estado del Medio Ambiente. Ministerio Del Medio Ambiente. 2020. https: //sinia.mma.gob.cl/estado-del-medio-ambiente/informe-del-estado-del-medio-ambiente-2020/. Accessed December 12, 2021.

IPPC. The Working Group I contribution to the Sixth Assessment Report addresses the most up-to-date physical understanding of the climate system and climate change, bringing together the latest advances in climate science. In: Climate Change 2021: The Physical Science Basis. Cambridge University Press; 2021. ISBN 9780080967899. https: //www.ipcc.ch/report/ar6/wg1/ Accessed December 30, 2021.

Bárcena A, Prado A, Samaniego J, Pérez R. La Economía del Cambio Climático en Chile. Comisión Económica para América Latina y el Caribe (CEPAL): Santiago, Chile: 2012. http: //repositorio.cepal.org/bitstream/handle/11362/35372/1/S2012058_es.pdf. Accessed November 19, 2021.

Torres D, Toro N, Galvez E, Castillo D, Bermudez SA, Navarra A. Temporal Variography for the Evaluation of Atmospheric Carbon Dioxide Monitoring. IEEE Journal of Selected Topics in Applied Earth Observations and Remote Sensing 2022; 15: 80–8. https: //doi.org/10.1109/JSTARS.2021.3131414

Santibañez F. El cambio climático y los recursos hídricos de Chile. Agricultura Chilena: Reflexiones y Desafíos 2016: 147–78. https: //www.odepa.gob.cl/publicaciones/documentos-e-informes/el-cambio-climatico-y-los-recursos-hidricos-de-chile-diciembre-de-2016 Accessed July 03, 2021.

Roldán F, Salazar I, González G, Roldán W, Toro N. Flow-Type Landslides Analysis in Arid Zones: Application in La Chimba Basin in Antofagasta, Atacama Desert (Chile). Water 2022, Vol 14, Page 2225 2022; 14(14): 2225. https: //doi.org/10.3390/W14142225

Fuentes F, García C. Ciclo económico y minería del cobre en Chile. Revista CEPAL 2016; Abril: 165–92. https: //repositorio.cepal.org/handle/11362/40035 Accessed September 23, 2021.

Conejeros V, Pérez K, Jeldres RI, Castillo J, Hernández P, Toro N. Novel treatment for mixed copper ores: Leaching ammonia – Precipitation – Flotation (L.A.P.F.). Minerals Engineering 2020; 149 (December 2019) : 106242. https: //doi.org/10.1016/j.mineng.2020.106242

Ortlieb L. Eventos El Niño y episodios lluviosos en el desierto de Atacama: el registro de los últimos dos siglos. Bulletin de l’Institut Français d’Études Andines 1995; 24(3): 519–37

Vargas G, Ortlieb L, Rutllant J. Aluviones históricos en Antofagasta y su relación con eventos El Niño/Oscilación del Sur. Revista Geológica de Chile 2000; 27(2): 157–76. https: //doi.org/10.4067/S0716-02082000000200002

Arens FL, Airo A, Feige J, Sager C, Wiechert U, Schulze-Makuch D. Geochemical proxies for water-soil interactions in the hyperarid Atacama Desert, Chile. CATENA 2021; 206: 105531. https: //doi.org/10.1016/J.CATENA.2021.105531

Jordan TE, Kirk-Lawlor NE, Nicolás Blanco P, Rech JA, Cosentino NJ. Landscape modification in response to repeated onset of hyperarid paleoclimate states since 14 Ma, Atacama Desert, Chile. GSA Bulletin 2014; 126(7–8): 1016–46. https: //doi.org/10.1130/B30978.1

Placzek CJ, Matmon A, Granger DE, Quade J, Niedermann S. Evidence for active landscape evolution in the hyperarid Atacama from multiple terrestrial cosmogenic nuclides. Earth and Planetary Science Letters 2010; 295(1–2): 12–20. https: //doi.org/10.1016/J.EPSL.2010.03.006

Kappes DW. Precious Metal Heap Leach Design and Practice. Mineral processing plant design, practice, and control. Vancouver, Canada: Society for Mining, Metallurgy, and Exploration; 2002; 12

Schlesinger M, King M, Sole K, Davenport W. Extractive Metallurgy of Copper. Fifth Ed. Amsterdam, The Netherlands: Elsevier Ltd; 2011. ISBN 9780080967899.

Saldaña M, Rodríguez F, Rojas A, Pérez K, Angulo P. Development of an empirical model for copper extraction from chalcocite in chloride media. Hem Ind 2020; 74(5): 285–92. https: //doi.org/10.2298/HEMIND200424031S

Saldaña M, Gálvez E, Robles P, Castillo J, Toro N. Copper Mineral Leaching Mathematical Models - A Review. Materials 2022, Vol 15, Page 1757 2022; 15(5): 1757. https: //doi.org/10.3390/MA15051757

Saldaña M, Neira P, Gallegos S, Salinas-Rodríguez E, Pérez-Rey I, Toro N. Mineral Leaching Modeling Through Machine Learning Algorithms − A Review. Frontiers in Earth Science 2022; 10: 560. https: //doi.org/10.3389/feart.2022.816751

Mellado ME, Cisternas LA, Gálvez ED. An analytical model approach to heap leaching. Hydrometallurgy 2009; 95(1–2): 33–8. https: //doi.org/10.1016/j.hydromet.2008.04.009

Mellado ME, Casanova MP, Cisternas LA, Gálvez ED. On scalable analytical models for heap leaching. Computers and Chemical Engineering 2011; 35(2): 220–5. https: //doi.org/10.1016/j.compchemeng.2010.09.009

Mellado ME, Gálvez ED, Cisternas LA. On the optimization of flow rates on copper heap leaching operations. International Journal of Mineral Processing 2011; 101(1–4): 75–80. https: //doi.org/10.1016/j.minpro.2011.07.011

Mellado M, Cisternas L, Lucay F, Gálvez E, Sepúlveda F. A Posteriori Analysis of Analytical Models for Heap Leaching Using Uncertainty and Global Sensitivity Analyses. Minerals 2018; 8(2): 44. https: //doi.org/10.3390/min8020044

Dixon DG, Hendrix JL. A mathematical model for heap leaching of one or more solid reactants from porous ore pellets. Metallurgical Transactions B 1993; 24(6): 1087–102. https: //doi.org/10.1007/BF02661000

Dixon DG, Hendrix JL. Theoretical basis for variable order assumption in the kinetics of leaching of discrete grains. AIChE Journal 1993; 39(5): 904–7. https: //doi.org/10.1002/aic.690390520

Dixon DG, Hendrix JL. A general model for leaching of one or more solid reactants from porous ore particles. Metallurgical Transactions B 1993; 24(1): 157–69. https: //doi.org/10.1007/BF02657882

Torres D, Trigueros E, Robles P, Leiva WH, Jeldres RI, Toledo PG, Toro N. Leaching of pure chalcocite with reject brine and mno2 from manganese nodules. Metals (Basel) 2020; 10(11): 1–19. https: //doi.org/10.3390/met10111426

Saldaña M, Toro N, Castillo J, Hernández P, Navarra A. Optimization of the Heap Leaching Process through Changes in Modes of Operation and Discrete Event Simulation. Minerals 2019; 9(7): 421. https: //doi.org/10.3390/min9070421

Liu B. Uncertainty Theory. In Uncertainty Theory. 4th Ed., Springer-Verlag Berlin Heidelberg: Germany. 2007. https: //doi.org/10.1007/978-3-540-73165-8_5

Jaynes ET. Probability Theory. Cambridge: Cambridge University Press; 2003. https: //doi.org/10.1017/CBO9780511790423

Saldaña M, González J, Jeldres R, Villegas Á, Castillo J, Quezada G, Toro N. A Stochastic Model Approach for Copper Heap Leaching through Bayesian Networks. Metals (Basel) 2019; 9(11): 1198. https: //doi.org/10.3390/met9111198

Taha HA. Operations Research: An Introduction. 10th Ed., Essex, England: Pearson Education Limited; 2017. ISBN 9780134444017.

Petersen J. Heap leaching as a key technology for recovery of values from low-grade ores – A brief overview. Hydrometallurgy 2016; 165: 206–12. https: //doi.org/10.1016/j.hydromet.2015.09.001

McCoy JT, Auret L. Machine learning applications in minerals processing: A review. Minerals Engineering 2019; 132 (November 2018): 95–109. https: //doi.org/10.1016/j.mineng.2018.12.004

Peña-Graf F, Órdenes J, Wilson R, Navarra A. Discrete Event Simulation for Machine-Learning Enabled Mine Production Control with Application to Gold Processing. Metals 2022, Vol 12, Page 225 2022; 12(2): 225. https: //doi.org/10.3390/MET12020225