Copper strip corrosion testing in hydrocracked base oil in the presence of different inhibitors Technical paper

Main Article Content

Abstract

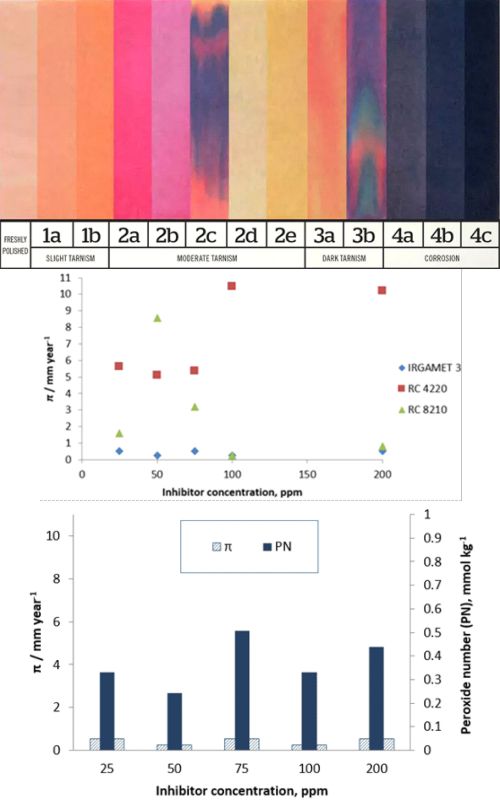

In this paper, the corrosion test of copper in hydrocracked base oil HC-6 was performed in the presence of an additive for extremely high pressures (EP additive) in different concentrations. EP additives are used to reduce wear in industrial applications, under high load conditions. Since most of these additives are sulfur-based, whose compounds can be corrosive at high temperatures, their use leads to corrosion of some materials. To prevent corrosion in the base oil with the EP additive, three commercial corrosion inhibitors are added. By chemical composition, the inhibitor RC 8210 is a derivate of dimercaptothiadiazole, RC 4220 is a synthetic neutral calcium sulfonate, and IRGAMET 39 is a derivative of tolutriazole. Efficiency of the inhibitors was monitored by standard test methods for corrosiveness to copper arising from petroleum products by the copper strip test (ASTM D-130) and the gravimetric method, while oxidation stability of the base oil was monitored by peroxide number determination. Oxidation was performed at 100±1 oC for 3 and 24 h. Results of these studies have shown that IRGAMET 39 is the most effective inhibitor in the presence of the EP additive at both examined oxidation times.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

References

Ahmad Khiara MS, Brown RCD, Lewin PL. Sacrificial Copper Strip Sensors for Sulfur Corrosion Detection in Transformer Oils. Measurement. 2019; 148: 1-6. https://doi.org/10.1016/j.measurement.2019.106887.

Alves SM, Schroeter RB, Bossardi JC dos S, Andrade CLF. Influence of EP additive on tool wear in drilling of compacted graphite iron. J. Braz. Soc. Mech. Sci. & Eng. 2011; 33: 197-202. https://doi.org/10.1590/S1678-58782011000200011.

Pawlak Z, Klamecki BE, Rauckyte T, Shpenkov GP, Kopkowski A. The tribochemical andmicellar aspects of cutting fluids. Tribol. Int. 2005; 38: 1–4. https://doi.org/10.1016/j.triboint.2004.04.004.

Boshui C, Nan Z, Kai L, Jianhua F. Enhanced Biodegradability, Lubricity and Corrosiveness of Lubricating Oil by Oleic Acid Diethanolamide Phosphate. Tribol. Ind. 2012; 34: 152-157. http://www.tribology.rs/journals/2012/2012-3/5.pdf.

Crutcher E. Copper Corrosion in the Absence of Corrosive Sulfur. In: Proceedings of TechCon US 2012 Conference. Austin, Texas, United States, 2012, pp 1-11.

Xue J, Yang X, Hu J. The Differences in Potential Corrosive Effects of Sulfides and Disulfides in Insulating Oils. IEEE T. Dielect. El. In. 2015; 22(1): 366-371. https://doi.org/10.1109/TDEI.2014.004210.

Venkata Lakshmi RA, Murthy TSR. Investigation of Copper corrosion in transformer oil. Int. J. Eng. Res. 2012; 1: 2278-0181. https://www.ijert.org/investigation-of-copper-corrosion-in-transformer-oil.

Ahmad Khiar MS, Brown RCD, Lewin PL. Detection of Sulfur Corrosion in Transformer Insulation Oils Using an Interdigitated Capacitive Sensor Based on Printed Circuit Board Technology. In: CEIDP 2017 - IEEE Conference on Electrical Insulation and Dielectric Phenomenon. Fort Worth, Texas, United States, 2017, pp. 278-281.

Wan T, Qian H, Zhou Z, Gong SK, Hu X, Feng B. Suppressive Mechanism of the Passivator Irgamet 39 on the Corrosion of Copper Conductors in Transformers. IEEE Trans. Dielectr. Electr. Insul. 2012; 19(2): 454-459. https://doi.org/10.1109/TDEI.2012.6180238.

Schaut A, Autru S, De Rop A, Eeckhoudt S. Effects of Irgamet®30 as Additive in Transformer Oil. IEEE Trans. Dielectr. Electr. Insul. 2012; 19(1): 175-180. https://doi.org/10.1109/TDEI.2012.6148516.

Cong H, Zhang M, Shu X, Li Q. Protective Performance of Different Passivators on Oil-Paper Insulation Containing Multiple Corrosive Sulphides. IEEE Access. 2019; 7: 4083-4090. https://doi.org/10.]09/ACCESS.2018.2888818.

Ling H, Jian S, Jun R, Qingjin M, Tsing Y. The adsorption of 2,5-dimercapto-1,3,4-thiadiazole (DMTD) on copper surface and its binding behavior. Chin. Sci. Bull. 2001; 46: 387–389. https://doi.org/10.1007/BF03183270.

Nassar AM, Ahmed NS, El-shazly RI, Abd el menem YK. Preparation and evaluation of the mixtures of sulfonate and phenate as lube oil additives. Int. J. Ind. Chem. 2017; 8:383-395. https://doi.org/10.1007/s40090-017-0128-x.

Zhongyi H, Liping X, Sheng H, Aixi C, Jianwei Q, Xisheng F. Tribological and Antioxidation Synergistic Effect Study of Sulfonate-Modified Nano Calcium Carbonate. PLOS ONE. 2013; 8(5): e62050. https://doi.org/10.1371/journal.pone.0062050.

OPTIMA GRUPA. https://optimagrupa.net/data/dokumenti/proizvodi/Tehni%C4%8Dki-list-HC-6.pdf. Acessed May 21, 2021.

Safety Data Sheet - Additive EP 7038 N. Additiv-Chemie Luers GmbH, Brendelweg 164, D-27755 Delmenhorst, Germany. Printing date 24.05.2015.

Safety Data Sheet - Irgamet 39. Ir https://vietducjsc.vn/upload/cdn/files/irgamet%2039%20msds(1).pdf Acessed May 21, 2021.

Safety Data Sheet - Additin RC 4220. https://www.tri-iso.com/rhein-chemie-additin-rc-4220.html Acessed May 21, 2021.

Safety Data Sheet - Additin RC 8210. https://www.yumpu.com/en/document/view/30819948/rc-8210-webshop-rhein-chemie Acessed May 21, 2021.

ASTM D 130 - 12: Standard Test Method for Corrosiveness to Copper from Petroleum Products by Copper Strip Test.

Stupišnek-Lisac E. Korozija i zaštita konstrukcijskih materijala. Zagreb, Fakultet kemijskog inženjerstva i tehnologije sveučilišta u zagrebu, 2007. ISBN: 978-953-6470-31-0

ASTM D 3703-99: Standard Test Method for Peroxide Number of Aviation Turbine Fuels.

Petrović ZR, Dugić PT, Aleksić VM, Botić TT, Kojić BN, Petrović RR. Uticaj kiselinom aktiviranog bentonita na oksidacionu stabilnost hidrokrekovanih baznih ulja. Glasnik hemičara, tehnologa i ekologa Republike Srpske. 2012; 7: 33-40. https://doi.org/10.7251/GHTE1207033P.

Zamberlin I. Aditivi za maziva. Maziva i podmazivanje. Zagreb: Savez Jugoslovenskih društava za primjenu goriva i maziva; 1986.