The effect of fibre morphology on packing phenomena and bed properties in coalescers Technical paper

Main Article Content

Abstract

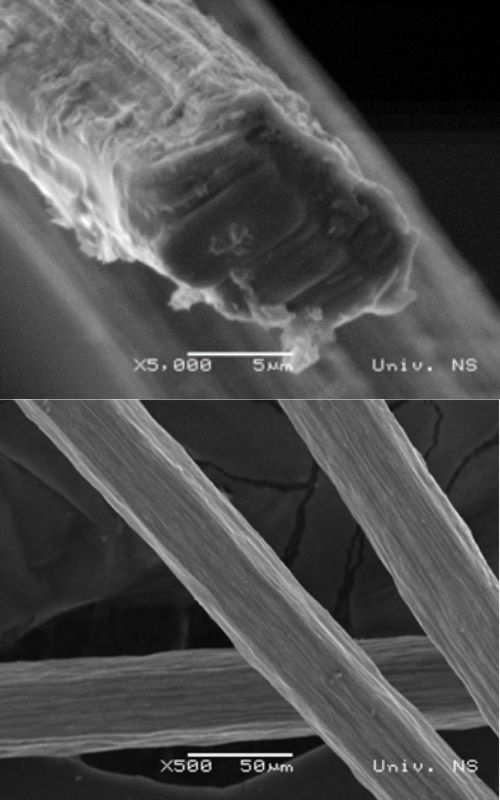

In this study, fibre morphology of waste materials and its effect on packing phenomena and bed properties were investigated. Nine waste materials were used in bed coalescers. By scanning electron microscopy, it was determined that surfaces of all fibres were smooth, while cross-section differed from circular, rectangular to irregular. The fibres with circular cross-sections had diameters in the range of 12±0.8 to 40±4 µm, while the fibres of polypropylene bags and sponges appeared as strips with the widths of 452±11 and 1001±14 µm, respectively. It was also noticed that polyurethane fibres were connected forming a sponge-like structure, while polyethylene terephthalate fibres were interconnected at some points. In this work, experimental dependence of bed porosity on bed permeability was established for all investigated materials, which allows forming a fibre bed with desired permeability. The exception was the bed formed of fibres of polypropylene bags, which had the largest dimensions and yielded a different porosity-permeability dependence.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

Funding data

-

Ministarstvo Prosvete, Nauke i Tehnološkog Razvoja

Grant numbers 172022;451-03-9/2021-14/200156;451-03-9/2021-14/200134 -

CEEPUS

Grant numbers CIII-SI-0708-08

References

[[1] Spielman LA. Separation of Finely Dispersed Liquid-Liquid Suspensions by Flow through Fibrous Media. Doctoral thesis, University of California, Berkeley, United States; 1968.

Spielman LA, Goren SL. Theory of Coalescence by Flow through Porous Media. Ind Eng Chem Fundam. 1972; 11 (1): 66-72., https://doi.org/10.1021/i160041a011

Spielman LA, Goren SL. Experiments in Coalescence by Flow through Fibrous Mats. Ind Eng Chem Fundam. 1972; 11 (1): 73-83., https://doi.org/10.1021/i160041a012

Amrei MM, Venkateshan DG, D’Souza N, Atulasimha J, Tafreshi HV. Novel Approach to Measuring the Droplet Detachment Force from Fibers. Langmuir. 2016; 32 (50): 13333-13339. https://doi.org/10.1021/acs.langmuir.6b03198

Bhattad P, Willson CS, Thompson KE. Effect of network structure on characterization and flow modeling using X-ray micro-tomography images of granular and fibrous porous media. Transp. Porous Media. 2011; 90 (2): 363-391. https://doi.org/10.1007/s11242-011-9789-7

Bradford SA, Torkzaban S. Colloid interaction energies for physically and chemically heterogeneous porous media. Langmuir. 2013; 29 (11): 3668-3676. https://doi.org/10.1021/la400229f

Dawar S, Chase GG. Correlations for transverse motion of liquid drops on fibers. Sep Purif Technol. 2010; 72 (3): 282-287. https://doi.org/10.1016/j.seppur.2010.02.018

Elimelech M, Chen JY, Kuznar ZA. Particle Deposition onto Solid Surfaces with Micropatterned Charge Heterogeneity: The “Hydrodynamic Bump” Effect. Langmuir. 2003; 19 (17): 6594-6597. https://doi.org/10.1021/la034516i

Sokolović D, Govedarica D, Šećerov-Sokolović RM. Review: Influence of fluid properties and solid surface energy on efficiency of bed coalescence. Chem Ind Chem Eng Q. 2018; 24 (3): 210-230. https://doi.org/10.2298/CICEQ170304034S

Shou D, Fan J, Zhang H, Qian X, Ye L. Filtration Efficiency of Non-Uniform Fibrous Filters. Aerosol Sci Technol. 2015; 49 (10): 912-919. https://doi.org/10.1080/02786826.2015.1083092

Zhu P, Kong T, Tian Y, Tang X, Tian X, Wang L. Superwettability with antithetic states: Fluid repellency in immiscible liquids. Mater Horiz. 2018; 5 (6): 1156-1165. DOI: 10.1039/c8mh00964c

Herminghaus S. Roughness-induced non-wetting. Europhys Lett. 2000; 52 (2): 165-170. https://doi.org/10.1209/epl/i2000-00418-8

Miwa M, Nakajima A, Fujishima A, Hashimoto K, Watanabe T. Effects of the surface roughness on sliding angles of water droplets on superhydrophobic surfaces. Langmuir 2000; 16 (13): 5754-5760. https://doi.org/10.1021/la991660o

Xia F, Jiang L. Bio-inspired, smart, multiscale interfacial materials. Adv Mater. 2008; 20 (15): 2842-2858. https://doi.org/10.1002/adma.200800836

Zhang P, Wang S, Wang S, Jiang L. Superwetting surfaces under different media: Effects of surface topography on wettability. Small. 2015; 11 (16): 1939-1946. https://doi: 10.1002/smll.201401869

Yohe ST, Freedman JD, Falde EJ, Colson YL, Grinstaff MW. A Mechanistic Study of Wetting Superhydrophobic Porous 3D Meshes. Adv Funct Mater. 2013; 23 (29): 3628-3637. https://doi.org/10.1002/adfm.201203111

Viswanadam G, Chase GG. Contact angles of drops on curved superhydrophobic surfaces. J Colloid Interface Sci. 2012; 367: 472-477. https://doi.org/10.1016/j.jcis.2011.11.004

Davoudi M, Fang J, Chase GG. Barrel shaped droplet movement at junctions of perpendicular fibers with different orientations to the air flow direction. Sep Purif Technol. 2016; 162: 1-5. https://doi.org/10.1016/j.seppur.2016.02.009

Šecerov Sokolović RM, Vulić TJ, Sokolović SM, Marinković-Nedučin RP. Effect of fibrous bed permeability on steady-state coalescence. Ind. Eng. Chem. Res. 2003; 42 (13): 3098-3102. https://doi.org/10.1021/ie020361i

Šećerov Sokolović R, Stanimirović O, Sokolović S. The influence of fibrous bed bulk density on the bed properties. Hem Ind. 2003; 57 (7-8): 335-340. (in Serbian) https://doi.org/10.2298/HEMIND0308335S

Agarwal S, von Arnim V, Stegmaier T, Planck H, Agarwal A. Role of surface wettability and roughness in emulsion separation. Sep Purif Technol. 2013; 107: 19-25. https://doi.org/10.1016/j.seppur.2013.01.001

Agarwal S, von Arnim V, Stegmaier T, Planck H, Agarwal A. Effect of Fibrous Coalescer geometry and operating conditions on emulsion separation. Ind Eng Chem Res. 2013; 52 (36): 13164-13170. https://doi.org/10.1021/ie4018995

Fahim M, Othman F. Coalescence of secondary dispersions in composite packed beds. J Dispersion Sci Technol. 1987; 8 (5-6): 507-523. https://doi.org/10.1080/01932698708943620

Das D, Ishtiaque SM, Das S. Influence of fibre cross-sectional shape on air permeability of nonwovens. Fiber Polym. 2015. 16 (1) 79-85. https://doi.org/10.1007/s12221-015-0079-9

Šećerov Sokolović RM, Govedarica DD, Sokolović DS. Selection of filter media for steady-state bed coalescers. Ind Eng Chem Res. 2014; 53 (6): 2484-2490. https://doi.org/10.1021/ie404013e

Kiralj A, Vulić T, Sokolović D, Šećerov Sokolović R, Dugić P. Separation of oil drops from water using stainless steel fiber bed. Chem Ind Chem Eng Q. 2017; 23 (2): 269-277. https://doi.org/10.2298/CICEQ160610041K

Govedarica DD, Šećerov-Sokolović RM, Kiralj AI, Govedarica OM, Sokolović DS, Hadnađev-Kostić MS. Separation of mineral oil droplets using polypropylene fibre bed coalescence, Hem ind. 2015; 69 (4): 339-346. https://doi.org/10.2298/HEMIND140322047G

Srđan S. Sokolović, Arpad I. Kiralj, Dunja S. Sokolović, Aleksandar I. Jokić, Application of waste polypropylene bags as filter media in coalescers for oily water treatment, Hem. Ind. 2019; 73 (3) 147-154 https://doi.org/10.2298/HEMIND190311013S

Das, D., Ishtiaque, S.M., Das, S. Influence of fibre cross-sectional shape on air permeability of nonwovens. Fiber Polym. 2015. 16, 79-85. https://doi.org/10.1007/s12221-015-0079-9

Cerepi A., Burlot R., Galaup S., Barde J. –P., Loisy C., Humbert L., Effects of porous solid structures on the electrical behaviour: prediction key of transport properties in sedimentary reservoir rock, Stud. Surf. Sci. Cat., 2002 (144), 483-490. https://doi.org/10.1016/S0167-2991(02)80171-9