Modeling the biodiesel production using the wheat straw ash as a catalyst Original scientific paper

Main Article Content

Abstract

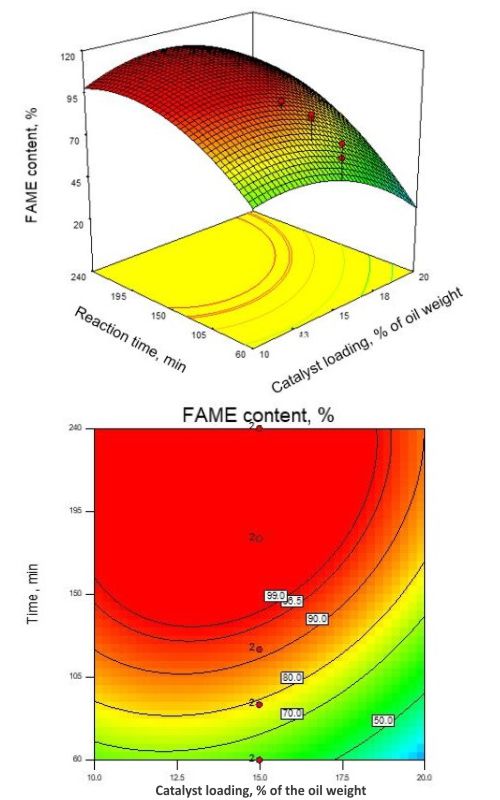

Wheat straw ash (WSA) was investigated as a new catalyst in biodiesel production from sunflower oil. The catalyst was characterized by temperature-programmed decomposition, X-ray powder diffraction, Hg porosimetry, N2 physisorption, and scanning electron microscopy - energy dispersive X-ray spectroscopy methods. The methanolysis reaction was tested in the temperature range of 55–65 oC, the catalyst loading range 10–20 % of the oil weight, and the methanol-to-oil molar ratio range 18 : 1–24 : 1. The reaction conditions of the sunflower oil methanolysis over WSA were optimized by using the response surface methodology in combination with the historical experimental design. The optimum process conditions ensuring the highest fatty acid methyl esters (FAME) content of 98.6 % were the reaction temperature of 60.3 oC, the catalyst loading of 11.6 % (based on the oil weight), the methanol-to-oil molar ratio of 18.3 :1, and the reaction time of 124 min. The values of the statistical criteria, such as coefficients of determination (R2 = 0.811, R2pred = 0.789, R2adj = 0.761) and the mean relative percent deviation (MRPD) value of 10.6 % (66 data) implied the acceptability and precision of the developed model. The FAME content after 4 h of reaction under the optimal conditions decreased to 37, 12, and 3 %, after the first, second, and third reuse, respectively.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

References

Global Bioenergy Statistics 2019, World Bioenergy Association, 2019. https://worldbioenergy.org/uploads/191129%20WBA%20GBS%202019_HQ.pdf, Assessed 25.2.2021

Shan R, Lua L, Shi Y, Yuan H, Shi J. Catalysts from renewable resources for biodiesel production. Energy Convers Manage 2018; 178: 277-289. https://doi.org/10.1016/j.enconman.2018.10.032

Baskar G., I. Aberna Ebenezer Selvakumari, R. Aiswarya, Biodiesel production from castor oil using heterogeneous Ni doped ZnO nanocatalyst, Bioresour Technol. 2018; 250: 793-798. https://doi.org/10.1016/j.biortech.2017.12.010

Veličković AV, Avramović JM, Stamenković OS, Veljković VB. Kinetics of the sunflower oil ethanolysis using CaO as catalyst. Chem Ind Chem Eng Q. 2016; 22: 409-418. https://doi.org/10.2298/CICEQ160106003V

Nakomčić-Smaragdakis B, Čepić Z, Dragutinović N. Wheat straw combustion process and its impact on air pollution. Cont Agric Eng. 2014; 40: 50-62. UDK: 662.767.2:536.46

Etim AO, Betiku E, Ajala SO, Olaniyi PJ, Ojumu TV. Potential of ripe plantain fruit peels as an ecofriendly catalyst for biodiesel synthesis: Optimization by artificial neural network integrated with genetic algorithm. Sustainability. 2018; 10: 1-15. https://doi.org/10.3390/su10030707

Betiku E, Ajala SO. Modeling and optimization of Thevetia peruviana (yellow oleander) oil biodiesel synthesis via Musa paradisiacal (plantain) peels as heterogeneous base catalyst: A case of artificial neural network vs. response surface methodology. Ind Crops Prod. 2014; 53: 314-322. https://doi.org/10.1016/j.indcrop.2013.12.046

Odude VO, Adesina AJ, Oyetunde OO., O.O. Adeyemi, N.B. Ishola, A.O. Etim, E. Betiku, Application of agricultural waste-based catalysts to trans esterification of esterified palm kernel oil into biodiesel: A case of banana fruit peel versus cocoa pod husk. Waste Biomass Valor. 2017; 10: 877-888. https://doi.org/10.1007/s12649-017-0152-2

Betiku E, Akintunde AM, Ojumu TV. Banana peels as a biobase catalyst for fatty acid methyl esters production using napoleons plume (Bauhinia monandra) seed oil: A process parameters optimization study. Energy 2016; 103: 797-806. https://doi.org/10.1016/j.energy.2016.02.138

Gohain M, Devi A, Deka D. Musa balbisiana Colla peel as highly effective renewable heterogeneous base catalyst for biodiesel production. Ind Crops Prod. 2017; 109: 8-18. https://doi.org/10.1016/j.indcrop.2017.08.006

Balaji M, Niju S. A novel biobased heterogeneous catalyst derived from Musa acuminate peduncle for biodiesel production – Process optimization using central composite design. Energy Convers Manage. 2019; 189: 118-131. https://doi.org/10.1016/j.enconman.2019.03.085

Balaji M, Niju S. Banana peduncle - A green and renewable heterogeneous base catalyst for biodiesel production from Ceiba pentandra oil. Renewable Energy 2020; 146: 2255-2269. https://doi.org/10.1016/j.renene.2019.08.062

Deka DC, Basumatary S. High quality biodiesel from yellow oleander (Thevetia peruviana) seed oil. Biomass Bioenergy 2011; 35: 1797-1803. https://doi.org/10.1016/j.biombioe.2011.01.007

Sarma AK, Kumar P, Aslam M, Chouhan APS. Preparation and characterization of Musa balbisiana Colla underground stem nano-material for biodiesel production under elevated conditions. Catal Lett. 2014; 144: 1344-1353. https://doi.org/10.1007/s10562-014-1206-8

Aslam M, Saxena P, Sarma AK. Green technology for biodiesel production from Mesua ferrea L. seed oil. Energy Environ. Res. 2014; 4 (2): 11-21. https://doi.org/10.5539/eer.v4n2p11

Betiku E, Etim AO, Pereao O, Ojumu TV. Two-step conversion of neem (Azadirachta indica) seed oil into fatty methyl esters using a heterogeneous biomass-based catalyst: An example of cocoa pod husk. Energy Fuels 2017; 31: 6182-6193. https://doi.org/10.1021/acs.energyfuels.7b00604

Vadery V, Narayanan BN, Ramakrishnan RM, Cherikkallinmel SK, Sugunan S, Narayanan DP, Sasidharan S. Room temperature production of jatropha biodiesel over coconut husk ash. Energy 2014; 70: 588-594. https://doi.org/10.1016/j.energy.2014.04.045

Hindryawati N, Maniam GP, Karim MR, Chong KF. Transesterification of used cooking oil over alkali metal (Li, Na, K) supported rice husk silica as potential solid base catalyst. Eng. Sci .Technol. Int. J. 2014; 17: 95-103. https://doi.org/10.1016/j.jestch.2014.04.002

Miladinović MR, Zdujić MV, Veljović ĐN, Krstić JB, Banković-Ilić IB, Veljković VB, Stamenković OS. Valorization of walnut shell ash as a catalyst for biodiesel production. Renewable Energy 2020; 147: 1033-1043. https://doi.org/10.1016/j.renene.2019.09.056

Kostić MD, Bazargan A, Stamenković OS, Veljković VB, McKay G. Optimization and kinetics of sunflower oil methanolysis catalyzed by calcium oxide-based catalyst derived from palm kernel shell biochar. Fuel 2016; 163: 304-313. https://doi.org/10.1016/j.fuel.2015.09.042

Laskar IB, Gupta R, Chatterjee S, Vanlalveni C, Rokhum L. Taming waste: Waste Mangifera indica peel as a sustainable catalyst for biodiesel production at room temperature. Renewable Energy 2020; 161: 207-220. https://doi.org/10.1016/j.renene.2020.07.061

Mendonça IM, Paes OARL, Maia PJS, Souza MP, Almeida RA, Silva CC, Duvoisin S Jr., de Freitas FA. New heterogeneous catalyst for biodiesel production from waste tucuma peels (Astrocaryum aculeatum Meyer): Parameters optimization study. Renewable Energy 2019; 130: 103-110. https://doi.org/10.1016/j.renene.2018.06.059

Uprety B.K, Chaiwong W, Ewelike C, Rakshit SK. Biodiesel production using heterogeneous catalysts including wood ash and the importance of enhancing byproduct glycerol purity. Energy Convers. Manage. 2016; 115: 191-199. https://doi.org/10.1016/j.enconman.2016.02.032

Aleman-Ramirez JL, Moreira J, Torres-Arellano S, Longoria A, Okoye PU, Sebastian PJ. Preparation of a heterogeneous catalyst from moringa leaves as a sustainable precursor for biodiesel production. Fuel 2021; 284: 118983. https://doi.org/10.1016/j.fuel.2020.118983

Barros S de S, Pessoa Junior WAG, Sá ISC, Takeno ML, Nobre FX, Pinheiro W, Manzato L, Iglauer S, de Freitas FA. Pineapple (Ananás comosus) leaves ash as a solid base catalyst for biodiesel synthesis. Bioresour Technol. 2020; 312: 123569. https://doi.org/10.1016/j.biortech.2020.123569

Nath B, Das B, Kalita P, Basumatary S. Waste to value addition: Utilization of waste Brassica nigra plant derived novel green heterogeneous base catalyst for effective synthesis of biodiesel. J Cleaner Prod. 2019; 239: 118112. https://doi.org/10.1016/j.jclepro.2019.118112

Kostić MD, Tasić MB, Đalović IG, Biberdžić MO, Mitrović PM, Stamenković OS, Veljković VB. Optimization of biodiesel production from corn oil by methanolysis catalyzed by corn cob ash. Recycl. Sustainable Dev. 2018; 11: 53-62. https://doi.org/10.5937/ror1801053K

Vinu V, Binitha NN. Lithium silicate based catalysts prepared using arecanut husk ash for biodiesel production from used cooking oil. Mater Today: Proc. 2020; 25: 241-245. https://doi.org/10.1016/j.matpr.2020.01.210

Changmai B, Rano R, Vanlalveni C, Rokhum L. A novel Citrus sinensis peel ash coated magnetic nanoparticles as an easily recoverable solid catalyst for biodiesel production. Fuel 2021; 286: 119447. https://doi.org/10.1016/j.fuel.2020.119447

Gouran A, Aghel B, Nasirmanesh F. Biodiesel production from waste cooking oil using wheat bran ash as a sustainable biomass. Fuel 2021; 295: 120542. https://doi.org/10.1016/j.fuel.2021.120542

Jaćimović G, Malešević M, Bogdanović D, Marinković B, Crnobarac J, Latković D, Aćin V. Wheat yield depending on long-term harvest residue incorporation. Letopis naučnih radova 2009; 33: 85-92. UDK: 633.11:631.82.

Kim SH, Gregory JM. Straw to grain ratio equation for combine simulation. J Biosyst Eng. 2015; 40: 314-319. http://dx.doi.org/10.5307/JBE.2015.40.4.314

Wieser H, Milijić V. Dostupnost poljoprivredne biomase u Srbiji, Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH. Availability of agro-biomass in Serbia. 2017. http://www.bioenergy-serbia.rs/images/documents/studies/20171028_Agrobiomass_Study.pdf, Assessed January 4, 2020.

Khushnood RA, Rizwan SA, Memon SA, Tulliani J-M, Ferro GA. Experimental investigation on use of wheat straw ash and bentonite in self-compacting cementitious system. Adv. Mater. Sci. Eng. 2014; 2014: 832508. http://dx.doi.org/10.1155/2014/832508

Ahmad MR, Sharif MB, Ali HA, Hussain M, Chen B. Experimental investigation of pozzolanic concrete containing wheat straw ash. Can. J. Civ. Eng. 2019; 46: 941-951. https://doi.org/10.1139/cjce-2017-0419.

Amin MN, Murtaza T, Shahzada K, Khan K, Adil M. Pozzolanic potential and mechanical performance of wheat straw ash incorporated sustainable concrete. Sustainability 2019; 11: 519. https://doi.org/10.3390/su11020519.

Jankovský O, Pavlíková M, Sedmidubský D, Bouša D, Lojka M, Pokorný J, Záleská M, Pavlí Z. Study on pozzolana activity of wheat straw ash as potential admixture for blended cements. Ceram.-Silik. 2017; 61: 327-339. http://dx.doi.org/10.13168/cs.2017.0032

Memon SA, Wahid I, Khan MK, Tanoli MA, Bimaganbetova M. Environmentally friendly utilization of wheat straw ash in cement-based composites. Sustainability 2018; 10: 1322. https://doi.org/10.3390/su10051322

Qudoos A, Kim HG, Atta-ur-Rehman, Jeon IK, Ryou J-S. Influence of the particle size of wheat straw ash on the microstructure of the interfacial transition zone. Powder Technol. 2019; 352: 453-461. https://doi.org/10.1016/j.powtec.2019.05.005

Sharma G, Singh K. Agro-waste ash and mineral oxides derived glass-ceramics and their interconnect study with Crofer 22 APU for SOFC application. Ceram. Int. 2019; 45: 20501-20508. https://doi.org/10.1016/j.ceramint.2019.07.029

Bartůněk V, Sedmidubský D, Bouša D, Jankovský O. Production of pure amorphous silica from wheat straw ash. Green Mater. 2018; 6: 1-5. https://doi.org/10.1680/jgrma.17.00035

Dodson J. Wheat straw ash and its use as a silica source. 2011; Ph. D. Thesis, Univ. York, UK, 2011.

Pokorný J, Pavlíková M, Jankovský O, Łagód G, Pavlík Z. Properties of wheat straw ash geopolymer for construction use. In: Proceedings of 19th International Multidisciplinary Scientific GeoConference SGEM 2019. Sofia, Bulgary, 2019, pp. 239-246. https://doi.org/10.5593/sgem2019/6.2/S26.031

Wang X, Yao K, Huang X, Chen X, Yu G, Liu H, Wang F, Fan M. Effect of CaO and biomass ash on catalytic hydrogasification behavior of coal char. Fuel 2019; 249: 103-111. https://doi.org/10.1016/j.fuel.2019.03.025

Ali MMM, Ahmed MJ. Adsorption behavior of doxycycline antibiotic on NaY zeolite from wheat (Triticum aestivum) straws ash. J. Taiwan Inst. Chem. Eng. 2017; 81: 218-224. https://doi.org/10.1016/j.jtice.2017.10.026.

Kumar A, Mandal A, Singh N. Rice and wheat straw ashes: Characterization and modeling of pretilachlor sorption kinetics and adsorption isotherm. J. Environ. Sci. Health B 2019; 54: 303-312. https://doi.org/10.1080/03601234.2018.1561059

Trivedi NS, Kharkar RA, Mandavgane SA. Use of wheat straw combustion residues for removal of chlorinated herbicide (2,4-dichlorophenoxyacetic acid). Waste Biomass Valor. 2019; 10: 1323-1331. https://doi.org/10.1007/s12649-017-0134-4

Đokić-Stojanović DR, Todorović ZB, Troter DZ, Stamenković OS, Veselinović LjM, Zdujić MV, Manojlović DD, Veljković VB. Triethanolamine as an efficient cosolvent for biodiesel production by CaO-catalyzed sunflower oil ethanolysis: An optimization study. Hem. Ind. 2019; 73: 351-362.https://doi.org/10.2298/HEMIND190822033D

Stanković M, Krstić J, Gabrovska M, Radonjić V, Nikolova D, Lončarević D, Jovanović D. Supported nickel-based catalysts for partial hydrogenation of edible oils. In: New Advances in Hydrogenation Processes - Fundamentals and Applications. IntechOpen; 2017: https://dx.doi.org/doi.org/10.5772/66967, https://www.intechopen.com/chapters/53666

Rouquerol F, Rouquerol J, Sing K. Adsorption by Powders and Porous Solids, Principles, Methodology and Applications. London, Academic Press; 1999.

Dubinin MM. Progress in Surface and Membrane Science. New York, Academic Press; 1975.

Barrett EP, Joyner LG, Halenda PP. The determination of pore volume and area distributions in porous substances. I. Computations from nitrogen isotherms. J. Am. Chem. Soc. 1951; 73: 373-380.

Lecloux A, Pirard JP. The importance of standard isotherms in the analysis of adsorption isotherms for determining the porous texture of solids. J Colloid Interface. Sci. 1979; 70: 265-281.

Veličković AV, Stamenković OS, Todorović ZB, Veljković VB. Application of the full factorial design to optimization of base-catalyzed sunflower oil ethanolysis. Fuel 2013; 104: 433-442. https://doi.org/10.1016/j.fuel.2012.08.015

Vassilev SV, Vassileva CG, Song YC, Li WY, Feng J. Ash contents and ash forming elements of biomass and their significance for solid biofuel combustion. Fuel 2017; 208: 377-409. https://doi.org/10.1016/j.fuel.2017.07.036

Singh B, Camps-Arbestain M, Lehmann J. Biochar: A guide to analytical methods. Australia, Clayton, Vic.: CSIRO Publishing; 2017.

Clemente JS, Beauchemin S, Thibault Y, MacKinnon T, Smith D. Differentiating inorganics in biochars produced at commercial scale using principal component analysis. ACS Omega 3 2018, 6: 6931-6944. https://doi. org /10.1021/acsomega.8b00523

Platonov AY, Evdokimov AN, Kurzin AV, Maiyorova HD. Solubility of Potassium Carbonate and Potassium Hydrocarbonate in Methanol. J. Chem. Eng. Data. 2002; 47: 1175-1176. https://doi/10.1021/je020012v

Lôbo IP, Ferreira SLC, da Cruz RS. Biodiesel: quality parameters and analytical methods. Quim. Nova 2009; 32: 1596-1608. https://doi.org/10.1590/S0100-40422009000600044

Lundstedt T, Seifert E, Abramo L, Thelin B, Nyström Å, Pettersen J, Bergman R. Experimental design and optimization. Chemom. Intell. Lab. Syst. 1998; 42: 3-40. https://doi.org/10.1016/S0169-7439(98)00065-3

Anderson MJ. Statistics Made Easy_ Blog.The DOE FAQ Alert. 10 (6). http://www.statease.com/news/faqalert10-06.html (2020). Accessed January 8, 2020.

Anderson MJ, Whitcomb PJ. RSM simplified: Optimizing processes using response surface methods for design of experiments. 2nd ed., New York, Productivity Press; 2005.

Vaz MAB, Pacheco PS, Seidel E Jr, Ansuj AP. Classification of the coefficient of variation to variables in beef cattle experiments. Cienc. Rural. 2017; 47: 1-4. http://dx.doi.org/10.1590/0103-8478cr20160946

Saldaña-Roblesa A, Guerra-Sánchez R, Maldonado-Rubio MI, Peralta-Hernández JM. Optimization of the operating parameters using RSM for the Fenton oxidation process and adsorption on vegetal carbon of MO solutions. J. Ind. Eng. Chem. 2014; 20: 848-857. https://doi.org/10.1016/j.jiec.2013.06.015