Prediction of rubber vulcanization using an artificial neural network Technical paper

Main Article Content

Abstract

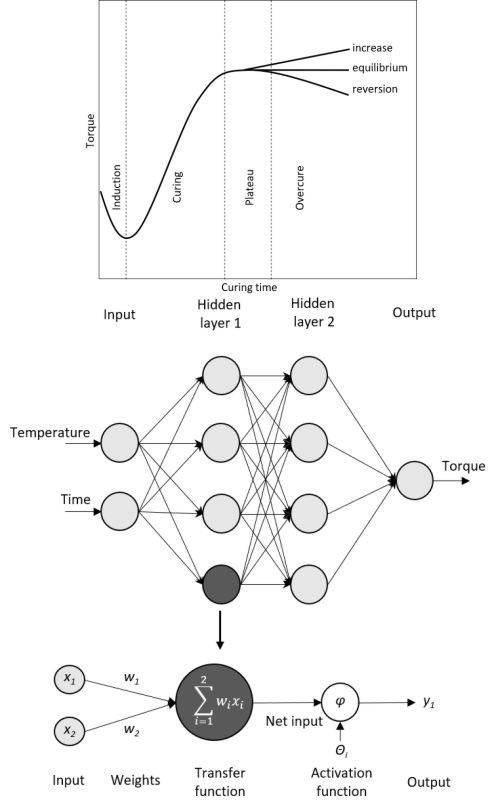

Determination of rubber rheological properties is indispensable in order to conduct efficient vulcanization process in rubber industry. The main goal of this study was development of an advanced artificial neural network (ANN) for quick and accurate vulcanization data prediction of commercially available rubber gum for tire production. The ANN was developed by using the platform for large-scale machine learning TensorFlow with the Sequential Keras-Dense layer model, in a Python framework. The ANN was trained and validated on previously determined experimental data of torque on time at five different temperatures, in the range from 140 to 180 oC, with a step of 10 oC. The activation functions, ReLU, Sigmoid and Softplus, were used to minimize error, where the ANN model with Softplus showed the most accurate predictions. Numbers of neurons and layers were varied, where the ANN with two layers and 20 neurons in each layer showed the most valid results. The proposed ANN was trained at temperatures of 140, 160 and 180 oC and used to predict the torque dependence on time for two test temperatures (150 and 170 oC). The obtained solutions were confirmed as accurate predictions, showing the mean absolute percentage error (MAPE) and mean squared error (MSE) values were less than 1.99 % and 0.032 dN2 m2, respectively.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

References

Ghoreishy MHR. A state-of-the-art review on the mathematical modeling and computer simulation of rubber vulcanization process. Iran Polym J (English Ed). 2016;25:89–109. https://doi.org/10.1007/s13726-015-0405-5

Alwaan IM. Rheological characterization and modeling of vulcanization kinetics of natural rubber/starch blends. J Appl Polym Sci. 2018;135:27–9. https://doi.org/10.1002/app.46347

Leroy E, Souid A, Deterre R. A continuous kinetic model of rubber vulcanization predicting induction and reversion. Polym Test. 2013;32:575–82. https://doi.org/10.1016/j.polymertesting.2013.01.003

Erfanian MR, Anbarsooz M, Moghiman M. A three dimensional simulation of a rubber curing process considering variable order of reaction. Appl Math Model. 2016;40:8592–604. https://doi.org/10.1016/j.apm.2016.05.024

Ghoreishy MHR, Rafei M, Naderi G. Optimizationofthevulcanizationprocessofathickrubber article using an advanced computer simulation technique. Rubber Chem Technol. 2012;85:576–89. https://doi.org/10.5254/rct.12.88917

Khang TH, Ariff ZM. Vulcanization kinetics study of natural rubber compounds having different formulation variables. J Therm Anal Calorim. 2012;109:1545–53. https://doi.org/10.1007/s10973-011-1937-3

Zhao L, Hu X. A variable reaction order model for prediction of curing kinetics of thermosetting polymers. Polymer (Guildf). 2007;48:6125–33. https://doi.org/10.1016/j.polymer.2007.07.067

El Labban A, Mousseau P, Bailleul JL, Deterre R. Numerical natural rubber curing simulation, obtaining a controlled gradient of the state of cure in a thick-section part. AIP Conf Proc. 2007;907:921–6. https://doi.org/10.1063/1.2729631

Wang B, Ma JH, Wu YP. Application of artificial neural network in prediction of abrasion of rubber composites. Mater Des. 2013;49:802–7. https://doi.org/10.1016/j.matdes.2013.01.047

Yu Y, Adu K, Tashi N, Anokye P, Wang X, Ayidzoe MA. RMAF: Relu-Memristor-Like Activation Function for Deep Learning. IEEE Access. 2020;8:72727–41. https://doi.org/10.1109/ACCESS.2020.2987829

Schwartz GA. Prediction of rheometric properties of compounds by using artificial neural networks. Rubber Chem Technol. 2001;74:116–23. https://doi.org/10.5254/1.3547632

Karaaǧaç B, Inal M, Deniz V. Artificial neural network approach for predicting optimum cure time of rubber compounds. Mater Des. 2009;30:1685–90. https://doi.org/10.1016/j.matdes.2008.07.010

Bera O, Pavličević J, Ikonić B, Lubura J, Govedarica D, Kojić P. A new approach for kinetic modeling and optimization of rubber molding. Polym Eng Sci. 2021;61:879–90. https://doi.org/10.1002/pen.25636

Ghoreishy MHR, Rafei M, Naderi G. Optimization of the vulcanization process of a thick rubber article using an advanced computer simulation technique. Rubber Chem Technol. 2012;85:576–89. https://doi.org/10.5254/rct.12.88917

Vijayabaskar V, Gupta R, Chakrabarti PP, Bhowmick AK. Prediction of properties of rubber by using artificial neural networks. J Appl Polym Sci. 2006;100:2227–37. https://doi.org/10.1002/app.22356

Kazi MK, Eljack F, Mahdi E. Predictive ANN models for varying filler content for cotton fiber/PVC composites based on experimental load displacement curves. Compos Struct. 2020;254:112885. https://doi.org/10.1016/j.compstruct.2020.112885

Elkatatny S. Real-Time Prediction of Rheological Parameters of KCl Water-Based Drilling Fluid Using Artificial Neural Networks. Arab J Sci Eng. 2017;42:1655–65. https://doi.org/10.1007/s13369-016-2409-7

Saldaña M, Ayala L, Torres D, Toro N. Global sensitivity analyses of a neural networks model for a flotation circuit. Hem Ind. 2020;74:247–56. https://doi.org/10.2298/HEMIND20060523S

Abadi M, Barham P, Chen J, Chen Z, Davis A, Dean J, Devin M, Ghemawat S, Irving G, Isard M, Kudlur M, Levenberg J, Monga R, Moore S, Murray DG, Steiner B, Tucker P, Vasudevan V, Warden P, Wicke M, Yu Y, Zheng X. TensorFlow: A system for large-scale machine learning, Proceedings of the 12th USENIX Symposium on Operating Systems Design and Implementati. November 2–4, 2016, Savannah, GA, USA, pp. 265-283.

Sarang P. Artificial Neural Networks with TensorFlow 2. Artif Neural Networks with TensorFlow 2. 2021. https://doi.org/10.1007/978-1-4842-6150-7

Bezabeh BB, Mengistu AD. The effects of multiple layers feed-forward neural network transfer function in digital based ethiopian soil classification and moisture prediction. Int J Electr Comput Eng. 2020;10:4073–9. https://doi.org/10.11591/ijece.v10i4. pp 4073-4079

Dučić N, Ćojbašić Ž, Slavković R, Jordović B, Purenović J. Optimizacija hemijskog sastava u proizvodnji flotacijskih kugli zasnovana na inteligentnoj softverskoj detekciji. Hem Ind. 2016;70:603–12. https://doi.org/10.2298/HEMIND150715068D

Lecun Y, Bengio Y, Hinton G. Deep learning. Nature. 2015;521:436–44. https://doi.org/10.1038/nature14539

Nasr MS, Moustafa MAE, Seif HAE, El Kobrosy G. Application of artificial neural network (ANN) for the prediction of EL-AGAMY wastewater treatment plant performance-EGYPT. Alexandria Eng J. 2012;51:37–43. https://doi.org/10.1016/j.aej.2012.07.005

Chasiotis VK, Tzempelikos DA, Filios AE, Moustris KP. Artificial neural network modelling of moisture content evolution for convective drying of cylindrical quince slices. Comput Electron Agric. 2020;172:105074. https://doi.org/10.1016/j.compag. 2019.105074

Park S, Park H. ANN Based Intrusion Detection Model. vol. 927. Springer International Publishing.; 2019. https://doi.org/10.1007/978-3-030-15035-8_40

Ramalingam V V, Ragavendran R. Prediction of liver disease using artificial neural network with adam optimizer. J Crit Rev. 2020;7:1287–92. https://doi.org/10.31838/jcr.07.17.164