Upgrading fuel potentials of waste biomass via hydrothermal carbonization Original scientific paper

Main Article Content

Abstract

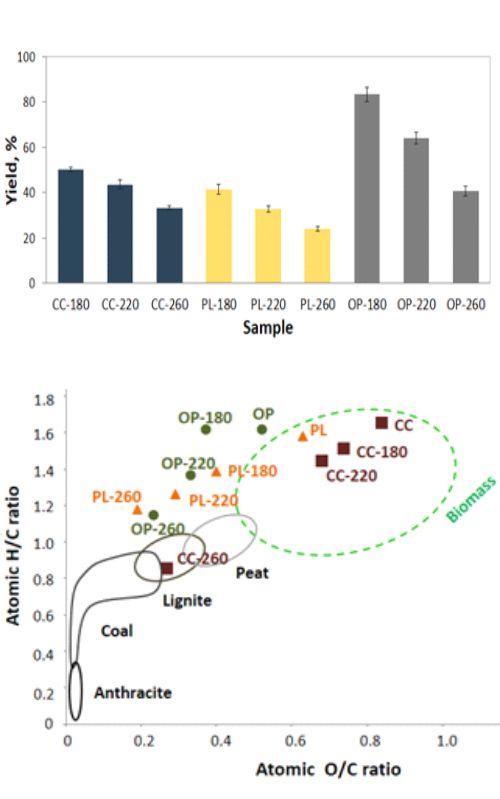

In recent decades, massive exploitation of fossil fuels caused a growing demand for the production of energies from renewable sources. Hydrochar obtained from waste biomass via hydrothermal carbonization (HTC) possesses good potentials as a biofuel. Therefore, we performed HTC of corn cob, paulownia leaves, and olive pomace at different temperatures (180, 220, and 260 oC). The main goal of this study was to comparatively evaluate the influence of HTC conditions on the structure and fuel characteristics of the obtained solids. The results showed that the yields of hydrochar decrease significantly with increasing temperature in all samples. The carbon content and higher heating value increased and reached the highest values in hydrochars obtained at 260 oC, while the content of volatile matter decreased. Furthermore, the Van Krevelen diagram reveals that the transformation of feedstock to lignite-like products upon HTC was achieved. In this study, the results showed that processes of dehydration and decarboxylation during HTC provoke intensive biomass transformation and that hydrochars obtained at higher temperatures have significantly enhanced fuel properties and fewer volatiles compared to the feedstock.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

References

Qi R, Xu Z, Zhou Y, Zhang D, Sun Z, Chen W, Xiong M. Clean solid fuel produced from cotton textiles waste through hydrothermal carbonization with FeCl3: Upgrading the fuel quality and combustion characteristics. Energy. 2021; 214: 118926 https://doi.org/10.1016/j.energy.2020.118926

Kabakcı SB and Baran SS. Hydrothermal carbonization of various lignocellulosics: Fuel characteristics of hydrochars and surface characteristics of activated hydrochars. Waste Manage. 2019; 100: 259-268 https://doi.org/10.1016/j.wasman.2019.09.021

Kambo SH and Dutta A. Strength, storage, and combustion characteristics of densified lignocellulosic biomass produced via torrefaction and hydrothermal carbonization. Appl Energy. 2014; 135: 182-191 https://doi.org/10.1016/j.apenergy.2014.08.094

Petrović J, Perišić N, Dragišić Maksimović J, Maksimović V, Kragović M, Stojanović M, Laušević M, Mihajlović M. Hydrothermal conversion of grape pomace: Detailed characterization of obtained hydrochar and liquid phase. J Anal Appl Pyrol. 2016; 118: 267-277 https://doi.org/10.1016/j.jaap.2016.02.010

Mihajlović M, Petrović J, Maletić S, Kragulj Isakovski M, Stojanović M, Lopičić Z, Trifunović S. Hydrothermal carbonization of Miscanthus × giganteus: Structural and fuel properties of hydrochars and organic profile with the ecotoxicological assessment of the liquid phase. Energy Convers Manage. 2018; 159: 254-263 https://doi.org/10.1016/j.enconman.2018.01.003

Pauline AL and Joseph K. Hydrothermal carbonization of organic wastes to carbonaceous solid fuel –A review of mechanisms and process parameters. Fuel. 2020; 279: 118472. https://doi.org/10.1016/j.fuel.2020.118472

Reza MT, Andert J, Wirth B, Busch D, Pielert J, Lynam JG, Mumme J. Hydrothermal Carbonization of Biomass for Energy and Crop Production. Appl Bioenergy. 2014; 1: 11-29 https://doi.org/10.2478/apbi-2014-0001

Wang T, Zhai Y, Zhu Y, Li C, Zeng G. A review of the hydrothermal carbonization of biomass waste for hydrochar formation: process conditions, fundamentals, and physicochemical properties. Renew Sustain Energy Rev. 2018; 90: 223-247 https://doi.org/10.1016/j.rser.2018.03.071

Funke A and Ziegler F. Hydrothermal carbonization of biomass: A summary and discussion of chemical mechanisms for process engineering. Biofuel Bioprod Biorefin. 2010; 4: 160-177 https://doi.org/10.1002/bbb.198

Cao X, Ro KS, Libra JA, Kammann CI, Lima I, Berge N, Li L, Li Y, Chen N, Yang J, Deng B, Mao J. Effects of Biomass Types and Carbonization Conditions on the Chemical Characteristics of Hydrochars. J Agric Food Chem. 2013; 61: 9401-9411 https://doi.org/10.1021/jf402345k

Jain A, Balasubramanian R, Srinivasan MP. Tuning hydrochar properties for enhanced mesopore development in activated carbon by hydrothermal carbonization. Micropor Mesopor Mat. 2015; 203: 178-185 https://doi.org/10.1016/j.micromeso.2014.10.036

Zhang L, Wang Q, Wang B, Yang G, Lucia LA, Chen J. Hydrothermal carbonization of corncob residues for hydrochar production. Energy Fuels. 2015; 29: 872-876 https://doi.org/10.1021/ef502462p

Fuertes AB and Sevilla M. Hierarchical microporous/mesoporous carbon nanosheets for high-performance supercapacitors. ACS Appl Mater Interf. 2015; 7: 4344-4353 https://doi.org/10.1021/am508794f

Petrović J, Stojanović M, Milojković J, Petrović M, Šoštarić T, Laušević M, Mihajlovć M. Alkali modified hydrochar of grape pomace as a perspective adsorbent of Pb2+ from aqueous solution. J Environ Manage. 2016; 182: 292–300. https://doi.org/10.1016/j.jenvman.2016.07.081

Azzaz AA, Jeguirim M, Kinigopoulou V, Doulgeris C, Goddard ML, Jellali S, Matei Ghimbeu C. Olive mill wastewater: From a pollutant to green fuels, agricultural and water source and bio-fertilizer-Hydrothermal carbonization. Sci Total Environ. 2020; 733: 139314 https://doi.org/10.1016/j.scitotenv.2020.139314

Kim D, Lee K, Park KY. Hydrothermal carbonization of anaerobically digested sludge for solid fuel production and energy recovery. Fuel. 2014; 130: 120-125 https://doi.org/10.1016/j.fuel.2014.04.030

Lu X, Ma X, Chen X. Co-hydrothermal carbonization of sewage sludge and lignocellulosic biomass: Fuel properties and heavy metal transformation behavior of hydrochars. Energy. 2021; 221: 119896 https://doi.org/10.1016/j.energy.2021.119896

Afolabi OOD, Sohail M, Cheng YL. Optimisation and characterisation of hydrochar production from spent coffee grounds by hydrothermal carbonization. Renew Energy. 2020; 147: 1380-1391 https://doi.org/10.1016/j.renene.2019.09.098

Kojić M, Petrović J, Petrović M, Stanković S, Porobić S, Marinović-Cincović M, Mihajlović M. Hydrothermal carbonization of spent mushroom substrate: Physicochemical characterization, combustion behavior, kinetic and thermodynamic study. J Anal Appl Pyrol. 2021; 155: 105028 https://doi.org/10.1016/j.jaap.2021.105028

Wang T, Zhai Y, Zhu Y, Gan X, Zheng L, Peng C, Wang B, Li C, Zeng G. Evaluation of the clean characteristics and combustion behavior of hydrochar derived from food waste towards solid biofuel production. Bioresour Technol. 2018; 266: 275-283 https://doi.org/10.1016/j.biortech.2018.06.093

Mendoza Martinez CL, Sermyagina E, Saari J, de Jesus MS, Cardoso M, de Almeida GM, Vakkilainen E. Hydrothermal carbonization of lignocellulosic agro-forest based biomass residues. Biomass Bioenergy. 2021; 147: 106004 https://doi.org/10.1016/j.biombioe.2021.106004

Sharma HB, Panigrahi S, Dubey BK. Hydrothermal carbonization of yard waste for solid bio-fuel production: Study on combustion kinetic, energy properties, grindability and flowability of hydrochar. Waste Manage. 2019; 91: 108-119 https://doi.org/10.1016/j.wasman.2019.04.056

Ischia G, Fiori L, Gao L, Goldfarb JL. Valorizing municipal solid waste via integrating hydrothermal carbonization and downstream extraction for biofuel production. J Clean Prod. 2021; 289: 125781 https://doi.org/10.1016/j.jclepro.2021.125781

Santos Santana M, Pereira Alves R, da Silva Borges WM, Francisquini E, Guerreiro MC. Hydrochar production from defective coffee beans by hydrothermal carbonization. Bioresour Technol. 2020; 300: 122653 https://doi.org/10.1016/j.biortech.2019.122653

Wang L, Li A, Chang Y. Hydrothermal treatment coupled with mechanical expression at increased temperature for excess sludge dewatering: Heavy metals, volatile organic compounds and combustion characteristics of hydrochar. Chem Eng J. 2016; 297: 1-10 https://doi.org/10.1016/j.cej.2016.03.131

McKendry P. Energy production from biomass (part 2): conversion technologies. Bioresour Technol. 2002; 83: 47-57 https://doi.org/10.1016/S0960-8524(01)00119-5

Ahmad M and Subawi H. New Van Krevelen diagram and its correlation with the heating value of biomass. Res J Agric Environ Manage. 2013; 2: 295-301 http://apexjournal.org/rjaem/archive/2013/Oct/fulltext/Ahmad%20and%20Subawi.pdf

Kim D, Lee K, Park KY. Upgrading the characteristics of biochar from cellulose, lignin, and xylan for solid biofuel production from biomass by hydrothermal carbonization. J Ind Eng Chem. 2016; 42: 95-100 https://doi.org/10.1016/j.jiec.2016.07.037

He C, Giannis A, Wang JY. Conversion of sewage sludge to clean solid fuel using hydrothermal carbonization: Hydrochar fuel characteristics and combustion behavior. Appl Energy. 2013; 111: 257-266 https://doi.org/10.1016/j.apenergy.2013.04.084

Akarsu K, Duman G, Yilmazer A, Keskin T, Azbar N, Yanik J. Sustainable valorization of food wastes into solid fuel by hydrothermal Carbonization. Bioresour Technol. 2019; 292: 121959 https://doi.org/10.1016/j.biortech.2019.121959