Study of microstructural and thermal properties of the Sn-Bi alloys Original scientific paper

Main Article Content

Abstract

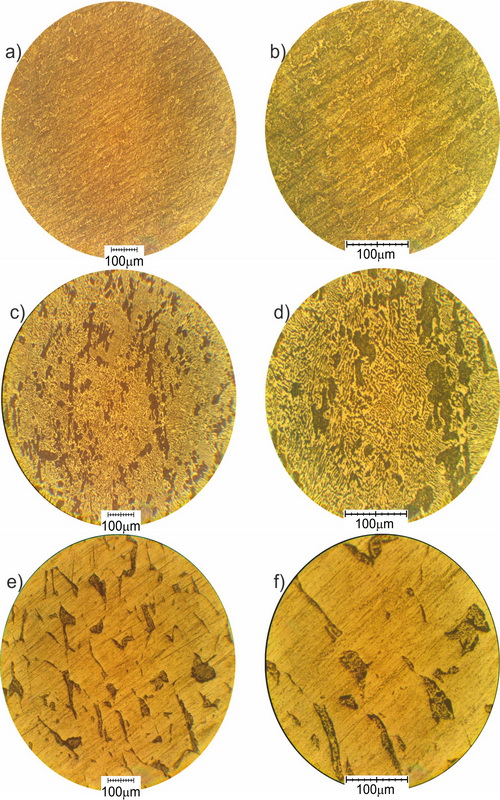

Lead-free solders have become a main focus of the electronic industry in recent years, because of the high toxicity of lead. Alloys based on the Sn-Bi system figure as potential replacements for Sn-Pb alloys in soldering due to favorable properties and low cost. One of the main advantages of these alloys are low melting temperatures, while additional advantages include good compatibility with substrates, low process temperature, high reliability, and potential applications in conjunction with reduced graphene oxide nanosheets as thermal interface materials. In this paper, characterization of microstructural and thermal properties as well as hardness measurements of seven alloys of different Sn-Bi compositions are performed. Structural properties of the samples were analyzed using optical microscopy and scanning electron microscopy and energy dispersive X-ray spectroscopy (SEM-EDS). Thermal conductivity of the samples was investigated using the xenon-flash method, and phase transition temperatures were measured using the differential scanning calorimetry (DSC) analysis.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

References

Frongia F, Pilloni M, Scano A, Ardu A, Cannas C, Musinu A, Borzone G, Delsante S, Novakovic R, Ennas G, Ennas. Synthesis and melting behaviour of Bi, Sn and Sn–Bi nanostructured alloy. J. Alloys Compd. 2015; 623: 7-14. https://doi.org/10.1016/j.jallcom.2014.08.122

Ren G, Wilding I, Collins M. Alloying influences on low melt temperature SnZn and SnBi solder alloys for electronic interconnections. J. Alloys Compd. 2016; 665: 251-260. https://doi.org/10.1016/j.jallcom.2016.01.006

Zhang X. P, Yu C. B, Zhang Y. P, Shrestha S, Dorn L. Processing treatment of a lead-free Sn–Ag–Cu–Bi solder by rapid laser-beam reflowing and the creep property of its soldered connection. J. Mater. Process. Technol. 2007; 192: 539-542. https://doi.org/10.1016/j.jmatprotec.2007.04.072

Kanlayasiri K, Ariga T. Physical properties of Sn58Bi–xNi lead-free solder and its interfacial reaction with copper substrate. Mater. Des. 2015; 86: 371-378. https://doi.org/10.1016/j.matdes.2015.07.108

Sun H, Li Q, Chan Y. A study of Ag additive methods by comparing mechanical properties between Sn57. 6Bi0. 4Ag and 0.4 wt% nano-Ag-doped Sn58Bi BGA solder joints. J. Mater. Sci.: Mater. Electron. 2014; 25: 4380-4390. https://doi.org/10.1007/s10854-014-2177-7

Silva B, Garcia A, Spinelli J. Complex eutectic growth and Bi precipitation in ternary Sn-Bi-Cu and Sn-Bi-Ag alloys. J. Alloys Compd. 2017; 691: 600-605. https://doi.org/10.1016/j.jallcom.2016.09.003

Abtew M, Selvaduray G. Lead-Free Solders in Microelectronics. Mater. Sci. Eng. 2000; 27: 95-141. https://doi.org/10.1016/S0927-796X(00)00010-3

Braga M. H, Vizdal J, Kroupa A, Ferreira J, Soares D, Malheiros L. F. The experimental study of the Bi–Sn, Bi–Zn and Bi–Sn–Zn systems. Calphad. 2007; 31: 468–478. https://doi.org/10.1016/j.calphad.2007.04.004

Mokhtari O, Nishikawa H. Correlation between microstructure and mechanical properties of Sn–Bi–X solders. Mater. Sci. Eng. 2016; 651: 831-839. https://doi.org/10.1016/j.msea.2015.11.038

Zhao J, Qi L, Wang X, Wang L. Influence of Bi on microstructures evolution and mechanical properties in Sn–Ag–Cu lead-free solder. J. Alloys Compd. 2004; 375: 196-201. https://doi.org/10.1016/j.jallcom.2003.12.005

Li J, Mannan S, Clode M, Whalley D, Hutt D. Interfacial reactions between molten Sn–Bi–X solders and Cu substrates for liquid solder interconnects. Acta Mater. 2006; 54: 2907-2922. https://doi.org/10.1016/j.actamat.2006.02.030

Shen J, Pu Y, Yin H, Luo D, Chen J. Effects of minor Cu and Zn additions on the thermal, microstructure and tensile properties of Sn–Bi-based solder alloys. J. Alloys Compd. 2014; 614: 63-70. https://doi.org/10.1016/j.jallcom.2014.06.015

Shalaby R. Effect of silver and indium addition on mechanical properties and indentation creep behavior of rapidly solidified Bi–Sn based lead-free solder alloys. Mater. Sci. Eng., A. 2013; 560: 86-95. https://doi.org/10.1016/j.msea.2012.09.038

Miao H, Duh J. Microstructure evolution in Sn–Bi and Sn–Bi–Cu solder joints under thermal aging. Mater. Chem. Phys.. 2013; 71: 255-271. https://doi.org/10.1016/S0254-0584(01)00298-X

Peng Y, Deng K. Fabrication of reduced graphene oxide nanosheets reinforced Sn–Bi nanocomposites by electro-chemical deposition. Compos. Part A Appl. Sci. Manuf. 2015; 73: 55–62. https://doi.org/10.1016/j.compositesa.2015.03.006

Billah M, Chen Q. Thermal conductivity of Ni-coated MWCNT reinforced 70Sn-30Bi alloy. Compos. B. Eng. 2017; 129: 162-168. https://doi.org/10.1016/j.compositesb.2017.07.071

Wang J, Wei H, He P, Lin T, Lu F. Microstructure and mechanical properties of tin-bismuth solder reinforced by aluminum borate whiskers. J. Electron. Mater. 2015; 44: 3872-3879. https://doi.org/10.1007/s11664-015-3896-0

Peng Y, Deng K. Study on the mechanical properties of the novel Sn–Bi/Graphene nanocomposite by finite element simulation. J. Alloys Compd. 2015; 625: 44-51. https://doi.org/10.1016/j.jallcom.2014.11.110

Lai Z, Ye D. Microstructure and fracture behavior of non eutectic Sn–Bi solder alloys. J. Mater. Sci.: Mater. Electron.2016; 27: 3182-3192. https://doi.org/10.1007/s10854-015-4143-4

Silva B, Reinhart G, Nguyen-Thi H, Mangelinck-Noël N, Garcia A, Spinelli J. Microstructural development and mechanical properties of a near-eutectic directionally solidified Sn–Bi solder alloy. Mater. Charact. 2015; 107: 43-53. https://doi.org/10.1016/j.matchar.2015.06.026

Gao L, Wang J, Lin T, He P, Lu F. Improvement of microstructure and mechanical properties of Sn-58Bi alloy with La2O3. In: 14th International Conference on Electronic Packaging Technology. Dalian, China, 2013, pp. 193-195.

Osório W, Peixoto L, Garcia L, Mangelinck-Noël N, Garcia A. Microstructure and mechanical properties of Sn–Bi, Sn–Ag and Sn–Zn lead-free solder alloys. J. Alloys Compd. 2013; 572: 97-106. https://doi.org/10.1016/j.jallcom.2013.03.234

Guo Q, Zhao Z, Shen C. Comparison study on microstructure and mechanical properties of Sn-10Bi and Sn-Ag-Cu solder alloys and joints. Microelectron Reliab. 2017; 78: 72-79.

Wang Q, Cheng X, Li Y, Yu G, Liu Z. Microstructures and Thermal Properties of Sn–Bi–Zn–Ga Alloys as Heat Transfer and Heat Storage Materials. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2019; 34: 676-683. https://doi.org/10.1007/s11595-019-2103-1

Wang F, Huang Y, ZhangZ, Yan C. Interfacial reaction and mechanical properties of Sn-Bi solder joints. Mater. 2017; 10: 920-936. https://doi.org/10.3390/ma10080920

Hua F, Zequn M, Glazer J. Eutectic Sn-Bi as an alternative to Pb-free solders. In: Proceedings of 48th Electronic Components and Technology Conference. Seattle, Washington, 1998, pp. 277-283.

Dong W, Shi Y, Xia Z, Lei Y, Guo F. Effects of trace amounts of rare earth additions on microstructure and properties of Sn-Bi-based solder alloy. J. Electron. Mater. 2008; 37: 982-991. https://doi.org/10.1007/s11664-008-0458-8

Morando C, Fornaro O, Garbellini O, Palacio H. Thermal properties of Sn-based solder alloys. J. Mater. Sci.: Mater. Electron. 2014; 25: 3440-3447. https://doi.org/10.1007/s10854-014-2036-6

Hu X, Li Y, Min Z. Interfacial reaction and growth behavior of IMCs layer between Sn–58Bi solders and a Cu substrate. J. Mater. Sci.: Mater. Electron. 2013; 24: 2027-2034 https://doi.org/10.1007/s10854-012-1052-7

Manasijević D, Balanović Lj, Ćosović V, Minić D, Premović M, Gorgievski M, Stamenković U, Talijan N. Thermal characterization of the In–Sn–Zn eutectic alloy. Metall. Mater. Eng. 2019; 25: 325-334. https://doi.org/10.30544/456

Marković B, Živković D, Manasijević D, Talijan N, Sokić M, Ćosović V. Phase Equilibria Calculation and Investigation of Hardness and Electrical Conductivity for Alloys in Selected Sections of Bi-Cu-Ni System. J. powder metall. min. 2012; 2:104 https://doi.org/10.4172/2168-9806.1000104

Kroupa A, Dinsdale A, Watson A, Vrestal J, Vízdal J, Zemanova A. The development of the COST 531 lead-free solders thermodynamic database. JOM. 2007; 59: 20-25. https://doi.org/10.1007/s11837-007-0084-6

Cao W, Chen S, Zhang F, Wu K, Yang Y, Chang Y, Schmid-Fetzer R, Oates W. PANDAT Software with PanEngine, PanOptimizer and PanPrecipitation for Multi-Component Phase Diagram Calculation and Materials Property Simulation. Calphad. 2009; 33: 328–342. https://doi.org/10.1016/j.calphad.2008.08.004

Vízdal J, Braga M, Kroupa A, Richter K, Soares D, Malheiros L, Ferreira J. Thermodynamic assessment of the Bi–Sn–Zn System. Calphad. 2007; 31: 438-448. https://doi.org/10.1016/j.calphad.2007.05.002

Parker W, Jenkins R, Butler C, Abbot G. Flash Method of Determining Thermal Diffusivity, Heat Capacity, and Thermal Conductivity. J. Appl. Phys. 1961; 32: 1679-84. https://doi.org/10.1063/1.1728417

Engineering ToolBox, (2005). Thermal Conductivity of Metals, Metallic Elements and Alloys. [online] Available at: https://www.engineeringtoolbox.com/thermal-conductivity-metals-d_858.html. Accessed January 11, 2021.

Indium Corp. Indalloy® 281 Bi-Sn Solder Alloy. http://www.matweb.com/search/datasheet.aspx?matguid=967a4cd7871b46fa9128a29c303cf8be. Accessed January 11, 2021.

ASM Handbook Volume 2. Properties and Selection: Nonferrous Alloys and Special-Purpose Materials. ASM International; 1990.