Glazing effect for producing environmentally friendly ceramics for cladding applications Technical paper

Main Article Content

Abstract

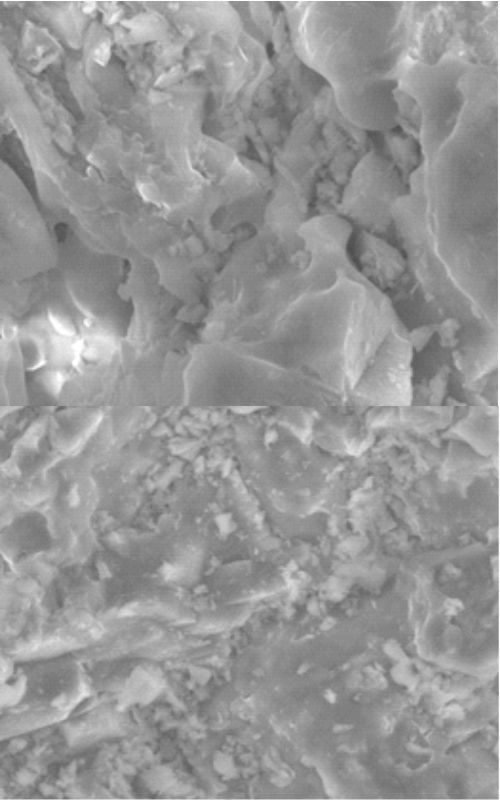

This paper presents results of comparative studies of environmental safety of ceramic materials, based on a low-plasticity clay with the introduction of galvanic sludge, boric acid and titanium dioxide in 3 different combinations. The experimental samples were manufactured under 15 MPa pressing pressure and at the maximum firing temperature of 1050 oC. Prior to the toxicological experiments, diurnal extracts of the materials into the model neutral and acidic media were obtained. The toxicological safety was determined by using the Daphnia mortality method, and by comparing the maximum permissible concentrations of heavy metals for drinking and household water with the heavy metals concentrations in diurnal extracts. The presented data show that the combined introduction of all the investigated additives results in the glazing effect of ceramic particles surfaces so that an environmentally safe material can be produced that exhibits sufficiently high-performance properties. The use of low-plastic clay and electroplating sludge expands the raw material base for producing ceramics and allows the disposal of environmentally hazardous compounds of heavy metals contained in electroplating sludge. Ceramic materials based on the developed charge composition can be used for producing items for external cladding for buildings and structures.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

References

Tang Z, Li W, Tam VWY., Xue C. Advanced progress in recycling municipal and construction solid wastes for manufacturing sustainable construction materials. Resour Conserv Recy. 2020; 6: 100036 https://doi.org/10.1016/j.rcrx.2020.100036

Perera S, Arulrajah A, Wong YC, Horpibulsuk S, Maghool F. Utilizing recycled PET blends with demolition wastes as construction materials. Constr Build Mater. 2019; 221: 200−209 https://doi.org/10.1016/j.conbuildmat.2019.06.047

Khan MdNN, Saha AK, Sarker PK. Reuse of waste glass as a supplementary binder and aggregate for sustainable cement-based construction materials: A review. J Build Eng. 2020; 28: 101052 https://doi.org/10.1016/j.jobe.2019.101052

Vorobeva AA, Shakhova VN, Pikalov ES, Selivanov OG, Sysoev ÉP, Chukhlanov VYu. Production of Facing Ceramic with a Glazing Effect Based on Low-Plastic Clay and Technogenic Waste from Vladimir Oblast. Glass Ceram. 2018; 75 (1-2): 51−54 https://doi.org/10.1007/s10717-018-0027-4

Vitkalova I, Torlova A, Pikalov E, Selivanov O. Development of environmentally safe acid-resistant ceramics using heavy metals containing waste. MATEC Web Conf. 2018; 193: 03035 https://doi.org/10.1051/matecconf/201819303035

Huyen PT, Dang TD, Roy S. Electrochemical copper recovery from galvanic sludge. Hydrometallurgy. 2016; 164: 295−303 https://doi.org/10.1016/j.hydromet.2016.06.028

Tognacchini A, Rosenkranz T, van der Ent A, Machinet GE, Echevarria G, Puschenreiter M. Nickel phytomining from industrial wastes: Growing nickel hyperaccumulator plants on galvanic sludges. J Environ Manag. 2020; 254: 109798 https://doi.org/10.1016/j.jenvman.2019.109798

Uvarova AS, Vitkalova IA, Pikalov ES, Selivanov OG. Application of tripolite in the production of facing ceramic material using cullet. Int J Emer Tr Eng Res. 2020; 8(9): 6042−6044 https://doi.org/10.30534/ijeter/2020/185892020

Shakhova VN, Vitkalova IA, Torlova AS, Pikalov ES, Selivanov OG. Receiving of ceramic veneer with the use of unsorted container glass breakage. Ecol Ind Rus. 2019; 23(2): 36-41 https://doi.org/10.18412/1816-0395-2019-2-36-41

Shakhova VN, Berezovskaya AV, Pikalov ES, Selivanov OG, Sysoev, ÉP. Development of Self-Glazing Ceramic Facing Material Based on Low-Plasticity Clay. Glass Ceram. 2019; 76(1-2): 11−15 https://doi.org/10.1007/s10717-019-00123-4

Vitkalova IA, Uvarova AS, Pikalov ES, Selivanov OG. Lanthanum oxide application for modifying the properties of chemically resistant ceramics produced with Galvanic Sludge additive. Int J Emer Tr Eng Res. 2020; 8(8): 4544−4547 https://doi.org/10.30534/ijeter/2020/81882020

GN 2.1.5.1315-03 Maximum permissible concentrations (MPC) of chemical substances in water bodies for drinking and domestic water supply. 2003. (In Russian)