Surface modification method of duplex type stainless steels by the pack boriding process Technical paper

Main Article Content

Abstract

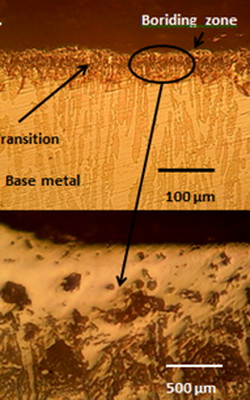

This work presents the investigation of a boriding process on two grades of stainless steel namely UNS32750 super duplex stainless steel and UNSS31803 duplex stainless steel in order to improve material properties and possibly to reduce catastrophic failure of industrial components. Usage of duplex stainless steels has become customary in the fields of oil and refinery, marine and pipeline applications due to increased corrosion resistance; however, these materials exhibit low wear characteristics. To overcome this problem, in this work the pack boriding process was employed. Evaluation of effects of the boriding process on the microstructure and mechanical properties was performed using scanning electron and optical microscopy, Vickers hardness tests and wear tests. It was shown that the 4 h process resulted in the greatest boriding layer thickness yielding the maximum surface hardness of 1407 HV in the super duplex stainless steel UNS32750 while this value was 1201 HV in the duplex stainless steel UNSS31803. Wear resistance of borided materials were up to 6-fold greater than those of non – treated materials. Also, the borided duplex materials were shown to be more suitable for industrial applications for valve and shaft components as compared to the boronized super duplex stainless steel.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

References

Tahchieva AB, Llorca-Isern N, Cabrera JM. Review -Duplex and Super duplex Stainless Steels: Microstructure and Property Evolution by Surface Modification Processes. Metals. 2019; 9: 1-11. https://doi.org/10.3390/met9030347

Nilsson JO. Super duplex stainless steels. Mater Sci Technol. 1992; 8: 685 – 700. https://doi.org/10.1179/mst.1992.8.8.685

Hasan R, Jauhari I, Yunus SM, Ramdan RD, Masdek NRN. A Study on Boronizing of Duplex Stainless Steel. Key Eng Mater. 2006; 306: 887–892. https://doi.org/10.4028/www.scientific.net/KEM.306-308.887

Martins M, Casteletti LC. Heat treatment temperature influence on ASTM A890 GR 6A super duplex stainless steel microstructure. Mater Charact. 2005; 55: 225– 233. https://doi.org/10.1016/j.matchar.2005.05.008

Mestra A, Fargas G, Anglada M, Matew, Sliding wear behaviour of a duplex stainless steel, Key Eng Mater. 2009; 423: 125-130 https://doi.org/10.4028 /www.scientific.net/ KEM. A423.125

Nora R, Zinee TM, Abdelkader K, Youcef K, Ali O, Jiang X. Boriding and boronitrocarburizing effects on hardness, wear and corrosion behaviour of AISI 4130 steel. Revista Materia. 2019: 24: e-12327. https://doi.org/10.1590/S1517-707620190001.0609

Ozdemir O, Usta M, Bindal C, Ucisik HA. Hard iron boride (Fe2B) on 99.97 % pure iron. Vacuum. 2006; 80: 1391 – 1395. https://doi.org/10.1016/j.vacuum.2006.01.022

Jauhari I, Yusof HAM, Saidan R. Super plastic boronizing of duplex stainless steel under dual compression method. Mater Sci Eng A. 2011; 528: 8106-8110. https://doi.org/10.1016/j.msea.2011.07.054

Yuri FM, Andrey VS. Boriding of steel surface with beams of boron atoms. In: MATEC web of conference. Rostov State Transport University, Russia. 2018, 1-4. 326, 03004, 2018. https://doi.org/10.1051/matecconf/201822603004

Akshay AJ, Santosh SH. Pack boronizing of AISI 4140 steel: Boronizing mechanism and the role of container design. Mater Manufac Proc. 2014; 29: 1062-1072. https://doi.org/10.1080/10426914.2014.921705

Gunes I, Kanat S. Diffusion Kinetics and characterization of borided AISI D6 steel. Protec Met Phy Chem Surf. 2015; 51: 842-846. https://doi.org/10.1134/S2070205115050111

Haris NA, Alias SK, Abdullah B, Pahroraji HF, Najmie A. Abrasion and erosion wear properties of surface deformed stainless steel. ARPN J Eng Appl Sci. 2016; 11: 7717-7720.

Turkoglu T, Ay I. Analysis of boride layer thickness of borided AISI 430 by RSM. Int J Optim Cont: Theor Appl. 2019; 9: 39-44. https://doi.org/10.11121/ijocta.01.2019.00660

Boztepe MH, Bayramoglu M. Optimization of process parameter of boronized AISI 1050 steel using the Taguchi analysis. The 17th International Conference on Machine Design and Production, Bursa, Turkey, 2016, pp.1-11.

Kear G, Barker BD, Walsh FC. Electrochemical study of UNS S32550 super duplex stainless steel corrosion in turbulent seawater using rotating cylinder electrode. Corrosion. 2004; 60: 561-572. https://doi.org/10.5006/1.3287760

Gunes I, Uygunoglu T, Ergen A, Kisikcilar T, Aksoy E. Investigation of wear behaviour of borided DIN 20MoCr4 Steel. El-Cezeri J Sci Eng. 2015; 2: 53-58

Gunes I, Erdogan M, Giirhan Celik A. Corrosion behaviour and characterization of plasma nitrided and borided AISI M2 steel. Mater Res. 2014; 17: 612-618. https://doi.org/10.1590/S1516-14392014005000061

Campos-Silva I, Contla Pacheco AD, Ruiz Rios A, Martinez Trinidad J, Rodriguez Casro G, Meneses Amador A, Wong Angel WD. Effects of Scratch tests on the adhesive and cohesive properties of borided Inconel 718 superalloy. Surf Coat Technol. 2018; 349: 917-927. https://doi.org/10.1016/j.surfcoat.2018.05.086

Li P, Liu D, Bao W, Ma L, Duan Y. Surface characterization and diffusion model of pack borided TB2 titanium alloy. Ceram Int. 2018; 44: 18429-18437. https://doi.org/10.1016/j.ceramint.2018.07.060

Gunes I. Investigation of tribological properties and characterization of borided AISI 420 and AISI 5120 steels. Transac Ind Inst Met. 2013; 67, 359-365. https://doi.org/10.1007/s12666-013-0356-5

Krelling AP, Milan JC, Da Costa CE. Tribological behaviour of borided H13 steel with different boriding agents. Surf Eng. 2014; 31: 1-7. https://doi.org/10.1179/1743294414Y.0000000423

Sista V, Kahvecioglu O, Kartal G, Kim JH, Eryilmaz, EzdemirA. Evaluation of electro chemical boriding of Inconel 600. Surf Coat Technol. 2013; 215: 452-459.https://doi.org/10.1016/j.surfcoat.2012.08.083

Rahmani M, Eghlimi A, Shamania M. Evaluation of Microstructure and Mechanical Properties in Dissimilar Austenitic/Super Duplex Stainless Steel Joint. J Mater Eng Perfor. 2014; 23: 3745–3753. https://doi.org/10.1007/s11665-014-1136-z

Erdogan A. Investigation of high temperature dry sliding behaviour of borided H13 hot work steel with nanoboron powder. Surf Coat Technol. 2019; 357: 886-895. https://doi.org/10.1016/j.surfcoat.2018.10.066

Marcelo Martins AB, Casteletti LC. Heat treatment temperature influence on ASTM A890 GR 6A super duplex stainless steel microstructure. Mater Charact. 2005; 55: 225 – 233. https://doi.org/10.1016/j.matchar.2005.05.008

Aylor DM, Metals Handbook V-13, vol. 9, ASM Metals Park, OH, 1982, pp. 859–863

Ramakrishnan H, Balasundaram R. Experimental investigation of process parameters or pack boronizing of SS410 using anova and machine learning approaches. Surf Topogr: Metrol Prop. 2021; 9: 025046. https://doi.org/10.1088/2051-672X/ac0c8d

Salim S. Effects of boronizing process on the surface roughness and dimensions of AISI 1020, AISI 1040 and AISI 2714. J Mater Proc Technol. 2009; 209: 1736–1741. https://doi.org/10.1016/j.jmatprotec.2008.04.040