Chemically modified Jatropha curcas oil for biolubricant applications Original scientific paper

Main Article Content

Abstract

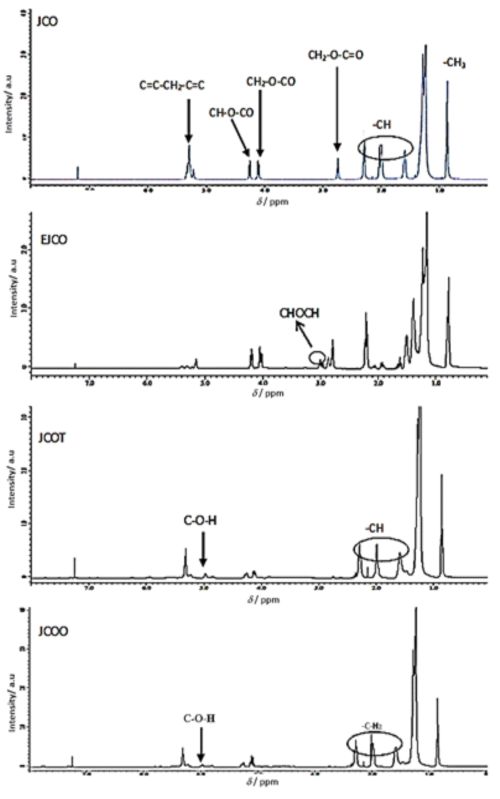

Jatropha curcas oil is one of interesting renewable resources for preparation of biolubricants. However, direct application of this oil as a biolubricant is restricted due to its low oxidative stability. This drawback can be overcome by molecule structural redesign through a chemical modification process at its unsaturated functional groups. Jatropha curcas oil was modified via epoxidation, ring opening and esterification processes. Its conversion to the epoxidized oil was performed by using in situ performic acid as a catalyst, then reaction with oleic acid in the presence of p-toluenesulfonic acid as a catalyst in the ring opening process. The final esterification process with oleic acid was catalyzed by sulfuric acid. Molecular structures of the modified oil were determined by measurements of the oxirane oxygen content and by Fourier-transform infrared (FTIR), proton and carbon nuclear magnetic resonance (1H NMR and 13C NMR) spectroscopy analyses. The results showed that the oxidative stability, viscosity, flash point and pour point of the final product were significantly improved. In specific, the ring opening and esterification processes inducing branching and bending in the final oil molecular structure have resulted in the improved viscosity index of 135, the pour point of -29 °C and the increased flash point of 250 °C.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

References

Campanella A, Rustoy E, Baldessari A, Baltanas M.A. Lubricants from chemically modified vegetable oils. Bioresour Technol. 2010; 101: 245–254.

Jumat S, Nadia S, Yousif E. Chemically modified biolubricant basestocks from epoxidized oleic acid: Improved low temperature properties and oxidative stability. J Saudi Chem Soc. 2011; 15: 195–201.

Jumat S, Nadia J. Oleic acid diesters: Synthesis, characterization and low temperature properties. Eur J Sci Res. 2009; 32; 216–222.

Farhoosh R, Einafshar S, Sharayei P. The effect of commercial refining steps on the rancidity measures of soybean and canola oils. Food Chem. 2009; 115: 933–938.

Erhan SZ, Asadauskas S. Lubricant basestocks from vegetable oils. Ind Crops Prod. 2000; 11: 277–282.

Cerretani L, Bendini A, Rodriguez-Estrada MT, Vittadini E, Chiavaro E. Microwave heating of different commercial categories of olive oil: Part I. Effect on chemical oxidative stability indices and phenolic compounds. Food Chem. 2009; 115: 1381–1388.

Moser BR, Sharma BK, Doll KM, Erhan SZ. Diesters from oleic acid:synthesis, low temperature properties, and oxidative stability. J Am Oil Chem Soc. 2007; 84: 675–680.

Jumat S, Nadia S. Substituted esters of octadecanoic acid as potential biolubricants. Eur J Sci Res. 2009; 31: 273–279.

Nirmal VP, Dineshbabu D. Performance and emission of Pongamia Pinnata oil as a lubricant in diesel engine. Int J Innov Res Sci Eng Technol. 2015; 4: 435–441.

Wu X, Zhang X, Yang S, Chen H, Wang D. The Study of epoxidized rapeseed oil used as a potential biodegradable lubricant. J Am Oil Chem Soc. 2000; 77: 561–563.

Jumat S, Nadia S. Modification of epoxidized ricinoleic acid for biolubricant base oil with improved flash and pour points. Asian J Chem. 2010; 22: 5468–5476.

Lathi P, Mattiasson B. Green approach for the preparation of biodegradable lubricant base stock from epoxidized vegetable oil. Appl Catal B. 2007; 69: 207-212.

Ebtisam KH, Elmelawy MS, Salah AK, Elbasuny NM. Manufacturing of environment friendly biolubricants from vegetable oils. Egypt. J. Pet. 2017; 26: 53–59.

Endalew AK, Kiros Y, Zanzi R. Inorganic heterogeneous catalysts for biodiesel production from vegetable oils. Biomass Bioenergy. 2011; 35: 3787–3809.

Tahira F, Hussain ST, Ali SD, Iqbal Z, Ahmad W. Homogeneous catalysis of high free fatty acid of waste cooking oil to fatty acid methyl esters (biodiesel). Int J Energy Power. 2012; 1: 31–36.

Hassani M, Amini G, Najafpour GD, Rabiee M. A two-step catalytic production of biodiesel from waste cooking oil. Int J Eng. 2013; 26: 563–570.

Panadare DC, Rathod VK. Applications of waste cooking oil other than biodiesel: A review. Iran J Chem Eng. 2015; 12: 55–76.

Arbain N, Jumat S. Synthesis and characterization of ester trimethylolpropane Jatropha curcas oil as biolubricant base stock. J Sci Technol. 2010; 2: 47–58.

Muhammad FM, Gunam R, Tinia IMG, Azni I. Temperature dependence on the synthesis of Jatropha biolubricant. IOP Conf Series: Mater Sci Eng. 2011; 17: 1–11.

Jumat S, Noor HA. The effects of various acid catalyst on the esterification of Jatropha curcas oil based trimethylolpropane ester as biolubricant base stock. J Chem. 2011; 8: 33–40.

Sharma A, Adhvaryu A, Liu Z, Erhan SZ. Chemical modification of vegetable oils for lubricant applications. J Am Oil Chem Soc. 2006; 83: 129–136.

Menkiti MC, Ocheje O, Agu CM. Production of environmentally adapted lubricant basestock from Jatropha curcas specie seed oil. Int J Ind Chem. 2017; 8: 133–144.

Sharma A, Adhvaryu A, Liu Z, Erhan SZ. Chemical modification of vegetable oils for lubricant applications. J Am Oil Chem Soc. 2006; 83: 129–136.

Moser BR, Erhan SZ. Preparation and evaluation of a series of α-hydroxy ethers from 9, 10-epoxystreates. Eur J Lipid Sci Technol. 2007; 109: 206–213.

Wang R, Schuman TP. Vegetable oil-derived epoxy monomers and polymer blends: A comparative study with review. eXPRESS Polym Lett. 2013; 7:272–292.

Yunus R, Razi AF, Iyuke TL, Idris A. Preparation and characterization of trimethylolpropane esters from palm kernel oil methyl esters. J Oil Palm Res. 2003; 15: 42–49.

Sharma BK, Doll KM, Erhan SZ. Ester hydroxy derivatives of methyl oleate: Tribological, oxidation and low temperature properties. Bioresour Technol. 2008; 99:7333–7340.

Akbar E, Yaakob Z, Kamarudin SK, Ismail M, Jumat S. Characteristic and composition of Jatropha curcas oil seed from Malaysia and its potential as biodiesel feedstock. Eur J Sci Res. 2009; 29: 396-403.

Jumat S, Abdullah BM, Nadia S. Improvement of physicochemical characteristics of monoepoxide linoleic acid ring opening for biolubricant base oil. J Biomed Biotechnol. 2011; 2011: 1–8.

Jumat S, Abdullah BM, Rahimi MY, Nadia S. Synthesis, reactivity and application studies for different biolubricants. Chem Cen J. 2014; 8: 1–11.

AOCS, Official methods and recommended practices of the American Oil Chemists Society, 4th ed., Champaign Illinois, USA, 1989.

Nadia S, Jumat S, Jantan F. Synthesis and characterization of palm kernel oil based trimethylolpropane ester. Asian J Chem. 2013; 25: 9751–9754.

Kishore, N.A. 2007. Guide to ASTM test methods for the analysis of petroleum products and lubricants, 2nd ed., ASTM International, West Conshohocken, PA, USA.

Yunus R, Fakhrul-Razi A, Ooi TL, Omar R, Idris A. Synthesis of palm oil based trimethylolpropane esters with improved pour points. Ind Eng Chem Res. 2005; 44: 8178–8183.

Nadia S, Jumat J, Emad Y. The physicochemical and tribological properties of oleic acid based triester biolubricants. Ind Crops Prod. 2011; 34: 1089–1096.

Abdo Ahmed W, Jumat S, Ambar YM. Lubricity characterizations of sebacic acid based ester. Int J Adv Sci Eng Inf Technol. 2014; 4: 1–6.

Stachowiak GW, Batchelor AW. Engineering Tribology, 3th ed., USA, New York, Elsevier: Butterworth-Heinemann; 2005.

Nor NM, Derawi D, Jumat S. Esterification and evaluation of palm oil as biolubricant base stock. Malaysian J Chem. 2019; 21: 28–35.

Owuna FJ, Dabai MU, Sokoto MA, Dangoggo SM, Bagudo BU, Birnin-Yauri UA, Hassan LG, Sada I, Abubakar AL, Jibrin MS. Chemical modification of vegetable oils for the production of biolubricants using trimethylolpropane: A review. Egypt J Pet. 2020; 29: 75–82.

Timothy YW, Sunday AL, Asipita SA, Moses AO. Nigeria Jatropha oil as suitable basestock for biolubricant production. J Tribol. 2019; 23: 97–112.

Jagadeesh KM, Satish VK, Venkatesh K, Kathyayini N. Evironmentally friendly functional fluids from renewable and sustainable sources – A review. Renew Sustain Energy Rev. 2018; 18: 1787–1801.

Jumat S, Abdullah BM, Yusop RM, Nadia S. Synthesis and optimization ring opening of monoepoxide linoleic acid using p-toluenesulfonic acid. SpringerPlus. 2013; 2: 1–14.

Bilal S, Mohammed-Dabo I, Nuhu M, Kasim S, Almustapha I, Yamusa Y. Production of biolubricant from Jatropha curcas seed oil. J Chem Eng Mater Sci. 2013; 4: 72-79.