Decay of the melt stream during dispersion in granulation devices

Main Article Content

Abstract

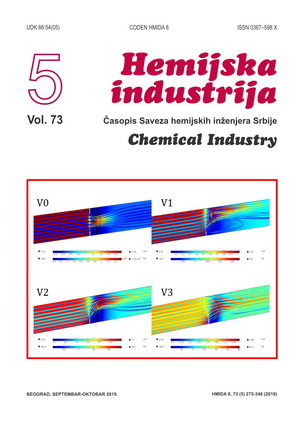

The aim of the article is a theoretical description and experimental study of the melt jet expiration process from a perforated shell of a vibrating granulator. Mathematical modeling of hydrodynamic flows was carried out based on the points of classical fluid and gas mechanics and technical hydromechanics. Reliability of the obtained experimental results is based on the application of time-tested in practice methods. Hydrodynamic properties of the liquid jet outflow were obtained. The presented mathematical model allows calculation of the radial component of the jet outflow velocity, as well as determination of the influences of physical and chemical properties of the liquid and the outflow hole diameter on the jet length and flow velocity along the axis to its disintegration into separated drops. The developed mathematical model extended with the theoretical description of the melt dispersion process from rotating perforated shells allowed us to improve design of the granulator to stabilize hydrodynamic parameters of the melt movement. The nitrogen fertilizers melt disperser was investigated regarding industrial-scale production and operating parameters of the process of jet decay into drops, drop size and monodispersity level were optimized.

Article Details

Issue

Section

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

References

Feng L, Liu M, Wanga J, Sunc J, Wanga J, Maoa Y. Study on the flow instability of a spray granulation tower. Sep Purif Technol. 2016; 169:210−222.

Artyukhov AE, Obodiak VK, Boiko, PG, Rossi PC. Computer modeling of hydrodynamic and heat-mass transfer processes in the vortex type granulation devices. CEUR Workshop Proceedings. 2017; 1844: 33-47.

Artyukhov AE, Sklabinskyi VI. Hydrodynamics of gas flow in small-sized vortex granulators in the production of nitrogen fertilizers. Chem Chem Technol. 2015; 9(3): 337-342.

Urea Casale S.A. [E-text type]. Location of document: http://www.casale.ch/. date of access 22.09.2019

Kahl Group [E-text type]. Location of document: http://www.amandus-kahl-group.de. date of access 22.09.2019

Stamicarbon [E-text type]. Location of document: http://www.stamicarbon.ru. date of access 22.09.2019

Toyo Engineering Corporation [E-text type]. Location of document: http://www.toyo-eng.com. date of access 22.09.2019

Glatt Innovative Technologies for Granules and Pellets [[E-text type]. Location of document: http://www.glatt.com. date of access 22.09.2019

Artyukhov AE, Sklabinskyi VI. Theoretical analysis of granules movement hydrodynamics in the vortex granulators of ammonium nitrate and carbamide production. Chem Chem Technol. 2015; 9(2): 175−180.

Sklabinskyi VI, Skydanenko MS., Kononenko NP. Technical audit of melt granulation knots in the production of mineral fertilizers using tower method. Tech Aud Prod Res. 2014; 3(2): 16−23.

Norsk Hydro [E-text type]. Location of document: https://www.hydro.com/en

Sklabinskyi VI, Artyukhov AE, Kononenko MP, Rossi PC. Quality improvement of granular nitrogen fertilizer in the prilling plants. In CLICAP 2015: Congreso Latinoamericano de Ingeniería y Ciencias Aplicadas. Argentina, 2015, pp. 611-618.

Wu Y, Bao C, Zhou Y. An Innovated Tower-fluidized Bed Prilling Process. Chin J Chem. Eng. 2007; 15: 424–428.

Saleh SN, Ahmed SM, Al-mosuli D, Barghi S. Basic design methodology for a prilling tower. Can J Chem Eng. 2015; 93: 1403–1409.

Gezerman AO, Corbacioglu BD. New approach for obtaining uniform-sized granules by prilling process. Chem Eng Elixir Chem Eng. 2011; 40: 5225–5228.

White F. Fluid Mechanics. Kindle Edition; 2015.

Cengel YA, Cimbala JM. Fluid Mechanics. Special India; 2016.

Harris FE. Mathematics for Physical Science and Engineering: Symbolic Computing Applications in Maple and Mathematica, Academic Press; 2014.

Hannan Z. wxMaxima for Calculus I. Zachary Hannan; 2015.

Hannan Z. wxMaxima for Calculus II. Zachary Hannan; 2015.

Vibrating granulator. Technical and commercial offer [E-text type]. Location of document: http://pohnv.teset.sumdu.edu.ua/uk/research/know-how.html (in Ukrainian) date of access 22.09.2019

Barsky E. Entropic Invariants of Two-Phase Flows. Amsterdam: Elsevier; 2015.

Artyukhov A, Sklabinskiy V., Ivaniia A. Electrical intelligent system for controlling the formation of monodisperse droplets in granulation devices based on magnetostrictive actuator. Proceedings of the International Conference on Modern Electrical and Energy Systems (MEES 2017). 2017; 280-283.

Holin BG . Centrifugal and vibratory granulators and liquid sprayers. Moscow: Mashinostroenie, 1977. (in Russian)

Schulz HE. Hydrodynamics – Concepts and Experiments. InTech; 2015.

Sahoo P. Probability and mathematical statistics. University of Louisville; 2013.

Shao J. Mathematical Statistics. Springer-Science+Business Media; 2003.

Rice JA. Mathematical Statistics and Data Analysis. Duxbury: Thomson Brooks/Cole; 2010.

Pradyot P. Handbook of Inorganic Chemicals. McGraw-Hill; 2002

Afanasyev VN. About some features of droplet flows Thermophysics of high temperatures.1998; 36(1): 94–101. (in Ukrainian)

Kreber [E-text type]. Location of document: https://www.kreber.nl/markets/prilling-nitrates date of access 22.09.2019

Research Institute at the Chemical plant [E-text type]. Location of document: https://www.niichimmash.ru/ date of access 22.09.2019

Bin L, Zhongping X, Huixun L, Carlessi L. Prilling tower and process, in particular for producing urea WO No 2014/060951, 2014.

Snyder DM, Rizzi E. Granulation apparatus. IN No 224039, 2008.

Rizzi E. Granulation Process and Apparatus. 2010/0289165, 2010.

Bugarova Z, Polak A, Batyka D, Papp J. Process of preparation of granulated ammonium nitrate-sulphate fertilizer. EP No 1595860, 2010.

Artyukhov AE, Sklabinskyi VI. Experimental and industrial implementation of porous ammonium nitrate producing process in vortex granulators. Nauk Visn Nats Hirn Univ. 2013; 6: 42−48.