Experimental analysis of atmospheric corrosion of steel S235JR in industrial environment Original scientific paper

Main Article Content

Abstract

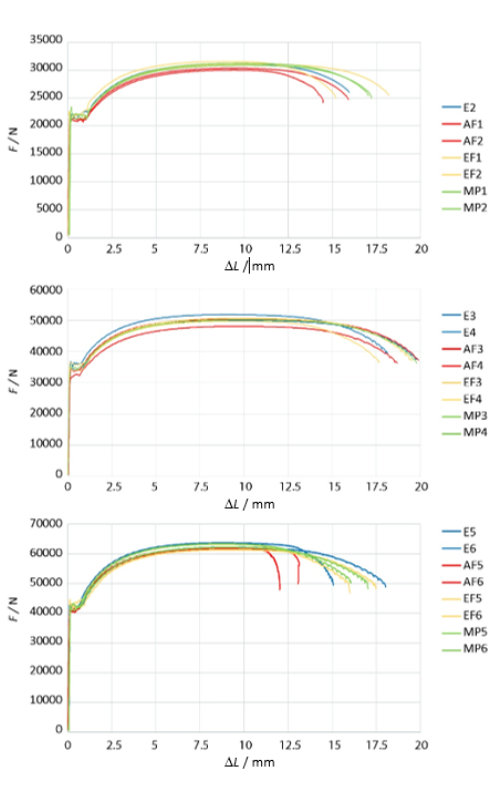

The aim of this study was evaluation of atmospheric corrosion of structural steel S235JR in an industrial environment. General corrosion testing was carried out for six months in the field, at selected atmospheric corrosion stations, near the Sulphuric acid plant, in the Electrolytic refining plant and next to the automatic air quality monitoring station in the city of Bor, Serbia. The results were compared with the standard specimens stored in the laboratory. The steel S235JR specimens were characterized regarding mechanical characteristics by tensile testing. With the aim of assessing the mutual effect of corrosion and polluted industrial environment meteorological parameters were also determined, as well as pollutants in the atmosphere (mainly SO2). The X-ray diffraction method was used to identify the composition of corrosion products. Research within this work enabled a better understanding of the behavior of structural steel S235JR in which there was a reduction in load capacity due to corrosion. The corrosion rates obtained under each tested exposure condition showed noticeable differences. It was found that depending on the content of pollutants in the atmosphere and the location of the steel specimen, the corrosion products represented different compounds and solid phases.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

Funding data

-

Ministarstvo Prosvete, Nauke i Tehnološkog Razvoja

Grant numbers 451-03-66/2024-03/200052;200092;451-03-66/2024-03/200287

References

[1] Mendoza A, Corvo F. Outdoor and indoor atmospheric corrosion of carbon steel. Corros Sci. 1999; 41: 75-86. https://doi.org/10.1016/S0010-938X(98)00081-X

[2] Gil H, Calderón J. A, Buitrago C. P, Echavarría A, Echeverría F. Indoor atmospheric corrosion of electronic materials in tropical-mountain environments. Corros Sci. 2010; 52(2): 327-337. https://doi.org/10.1016/j.corsci.2009.09.019

[3] Del Angel-Meraz E, Corvo F, Hernandez-Morales N, Tejero-Rivas M. Particularities of indoor atmospheric corrosion of steel inside electric boxes in the tropical climate of Tabasco, Mexico. Indoor Built Environ. 2020; 30(10): 1609-1619. https://doi.org/10.1177/1420326X20950411

[4] Rajaković-Ognjanović V, Grgur B. Corroded scale analysis from water distribution pipes. Hem. Ind. 2011; 65(5): 507-515. https://doi.org/10.2298/HEMIND110523049R

[5] Xue X, Hua J, Wang F, Wang N, Li S. Mechanical Property Model of Q620 High-Strength Steel with Corrosion Effects. Buildings. 2022; 12: 1651. https://doi.org/10.3390/buildings12101651

[6] Zhao N, Zhang C. Experimental Investigation of the Mechanical Behavior of Corroded Q345 and Q420 Structural Steels. Buildings. 2023; 13: 475. https://doi.org/10.3390/buildings13020475

[7] Di Sarno L, Majidian A, Karagiannakis G. The Effect of Atmospheric Corrosion on Steel Structures: A State-of-the-Art and Case-Study. Buildings. 2021; 11: 571. https://doi.org/10.3390/buildings11120571

[8] Li F, Cui C, Ma R, Tian H. An experimental study on the corrosion behaviors and mechanical properties of Q345qD steel in neutral salt spray environment considering stress state. Dev Built Environ. 2023; 15: 100214. https://doi.org/10.1016/j.dibe.2023.100214

[9] Stefanović J, Dimitrijević S, Filipović S, Đorđević J. Evaluation of the corrosion resistance of steel elements in the industrially aggressive environments using the accelerated corrosion testing methods. Min Metall Eng Bor. 2023; 1: 53-60. https://doi.org/10.5937/mmeb2104053S

[10] Sanders C, Santucci R. Jr. Experimental Design Considerations for Assessing Atmospheric Corrosion in a Marine Environment: Surrogate C1010 Steel. Corros Mater Degrad. 2023; 4(1): 1-17. https://doi.org/10.3390/cmd4010001

[11] Parekh SP, Pandya AV, Kadiya HK. Progressive Atmospheric Corrosion Study of Metals Like Mild Steel, Zinc and Aluminum in Urban Station of Ahmedabad District. Int J Chemtech Res. 2012; 4: 1700-1774. http://dx.doi.org/10.1155/2009/807376

[12] ISO Standard 8407:2021 Corrosion of Metals and Alloys: Corrosivity of atmospheres: Removal of Corrosion Products from Corrosion Test Specimens. https://www.iso.org/standard/71866.html

[13] PDXL, Version 2.0. 3.0 Integrated X-ray Powder Diffraction Software, Rigaku Corporation. Tokyo, Japan; https://rigaku-pdxl.software.informer.com/2.0/

[14] Аnnual and monthly reports on ambient air quality in Bor for the period 2016-2017 (Archive MMI Bor), Mining and Metallurgy Institute Bor (MMI Bor), Laboratory for Chemical Testing, Department for Environmental Protection and Climate Change, Bor, Serbia.

[15] Annual report on air quality in the Republic of Serbia in 2016, Republic of Serbia, Ministry of Environmental Protection, Environmental protection agency, Belgrade, Serbia. https://sepa.gov.rs/wp-content/uploads/2024/10/Vazduh2016.pdf. Accessed 2017.

[16] Annual report on air quality in the Republic of Serbia in 2017, Republic of Serbia, Ministry of Environmental Protection, Environmental protection agency, Belgrade, Serbia. https://sepa.gov.rs/wp-content/uploads/2024/10/Vazduh2017.pdf Accessed 2018.

[17] Seechurn Y, Surnam B, Wharton J. Marine atmospheric corrosion of carbon steel in the tropical microclimate of Port Louis. Mater Cor. 2022; 73: 1474-1489. https://doi.org/10.1002/maco.202112871

[18] Pan C, Han W, Wang Z, Wang C, Yu G. Evolution of Initial Atmospheric Corrosion of Carbon Steel in an Industrial Atmosphere. JMEP. 2016; 25: 5382-5390. https://doi.org/10.1007/s11665-016-2312-0

[19] Wu H, Luo Y, Zhou G. The Evolution of the Corrosion Mechanism of Structural Steel Exposed to the Urban Industrial Atmosphere for Seven Years. Appl Sci. 2023; 13: 4500. https://doi.org/10.3390/app13074500

[20] Qin H, Liu J, Shao Q, Zhang X, Teng Y, Chen S, Zhang D, Bao S. Corrosion behavior and cellular automata simulation of carbon steel in salt-spray environment. Mater Degrad. 2024; 8: 29. https://doi.org/10.1038/s41529-024-00447-9

[21] De la Fuente D, Díaz I, Simancas J, Chico B, Morcillo M. Long-term atmospheric corrosion of mild steel. Cor Sci. 2011; 53: 604-617. https://doi.org/10.1016/j.corsci.2010.10.007

[22] Dhaiveegan P, Elangovan N, Nishimura T, Rajendran N. Weathering Steel in Industrial-Marine-Urban Environment: Field Study. MaterTrans. 2016; 57, (2): 148-155. https://doi.org/10.2320/matertrans.M2015345

[23] ISO Standard 9223:2012 Corrosion of metals and alloys — Corrosivity of atmospheres — Classification, determination and estimation. https://www.iso.org/standard/53499.html

[24] ISO Standard 9226:2012 Corrosion of metals and alloys—Corrosivity of atmospheres—Determination of corrosion rate of standard specimens for the evaluation of corrosivity. https://www.iso.org/standard/53502.html

[25] Montoya P, Díaz I, Granizo N, de la Fuente D, Morcillo M. An study on accelerated corrosion testing of weathering steel. Mater. Chem. Phys. 2013; 142: 220-228. https://doi.org/10.1016/j.matchemphys.2013.07.009

[26] Zhang Z, Xu Y, Qin G, Xu S, Li R. Deterioration of Mechanical Properties and the Damage Constitutive Model of Corroded Steel in an Industrial Environment. Materials. 2022; 15: 8841. https://doi.org/10.3390/ma15248841