Shape memory alloys: Properties, demands and opportunities in engineering applications PART I Technical paper

Main Article Content

Abstract

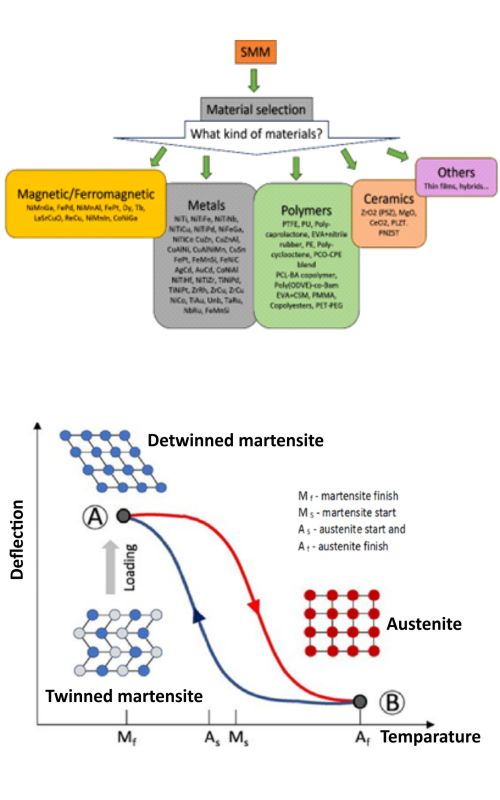

Shape memory alloys (SMAs) are a subclass of shape memory materials (SMMs), which are materials that, in response to a specific impact like thermal, mechanical, or magnetic changes, can "memorize" or hold into their prior form. This review addresses the properties, demands, and application prospects of SMAs, and provides a synopsis of recent advancements, as well as a historical background. Due to their special and exceptional qualities, SMAs have attracted a lot of interest and attention recently in a wide range of commercial applications; basic and applied research investigations have supported this commercial development. In order to shed light on design, issues faced by SMA developers, this paper explains the characteristics of these materials that make them perfectly suited for variety of applications, addressing also the accompanying constraints. This paper offers a pertinent overview of current SMA research.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

Funding data

-

Ministarstvo Prosvete, Nauke i Tehnološkog Razvoja

Grant numbers 451-03-47/2023-01/200135;451-03-47/2023-01/200026

References

Mohd Jani J, Leary M, Subic A, Gibson MA. A review of shape memory alloy research, applications and opportunities. Mater Des. 2014; 56: 1078-1113. https://doi.org/https://doi.org/10.1016/j.matdes.2013.11.084

Balasubramanian M, Srimath R, Vignesh L, Rajesh S. Application of shape memory alloys in engineering. J Phys Conf Ser. 2021; 2054(1): 12078. https://doi.org/10.1088/1742-6596/2054/1/012078

Shabalovskaya S, Anderegg J, Van Humbeeck J. Critical overview of Nitinol surfaces and their modifications for medical applications. Acta Biomater. 2008; 4(3): 447-467. https://doi.org/https://doi.org/10.1016/j.actbio.2008.01.013

Ivanić I. Slitine s prisjetljivosti oblika (II. dio): podjela, proizvodnja i primjena. Kem Ind. 2014; 63(9-10): 331-344. https://doi.org/10.15255/kui.2013.017 (in Croatian)

Benafan O. Shape memory alloys - not your ordinary metal. NASA Glenn Research Center; 2020. https://ntrs.nasa.gov/api/citations/20205009686/downloads/Shape-Memory-Alloys_Book_Final.pdf

Saha SS, Islam A. Shape Memory Materials - Concepts, Recent Trends and Future Directions. 7th International Conference on Informatics, Electronics & Vision, Kitakyushu, Japan, 2018. https://www.researchgate.net/publication/324970745_Shape_ Memory_Materials_-_Concepts_Recent_Trends_and_Future_Directions

Balasubramanian M, Srimath R, Vignesh L, Rajesh S. Application of shape memory alloys in engineering. J Phys Conf Ser. 2021; 2054(1): 12078. https://doi.org/10.1088/1742-6596/2054/1/012078

Machado LG, Lagoudas DC. Thermomechanical Constitutive Modeling of SMAs BT - Shape Memory Alloys.In: Modeling and Engineering Applications. Boston MA, US; 2008. pp. 121-187. https://doi.org/10.1007/978-0-387-47685-8_3

Popov P, Lagoudas DC. A 3-D constitutive model for shape memory alloys incorporating pseudoelasticity and detwinning of self-accommodated martensite. Int J Plast. 2007; 23(10): 1679-1720. https://doi.org/https://doi.org/10.1016/j.ijplas.2007.03.011

Naresh C, Bose PSC, Rao C. Shape memory alloys: a state of art review. IOP Conf Ser Mater Sci Eng. 2016; 149: 012054. https://doi.org/10.1088/1757-899X/149/1/012054

Vasudha N, Rao K. Shape memory alloy properties, modelling aspects and potential applications. J Phys Conf Ser. 2020; 1706: 12190. https://doi.org/10.1088/1742-6596/1706/1/012190

Shape Memory Alloys. https://civil.poriyaan.in/topic/shape-memory-alloys--sma--40134 Accessed January 7, 2024.

Chaudhari R, Vora JJ, Parikh DM. A review on applications of nitinol shape memory alloy. In: Recent Advances in Mechanical Infrastructure. Singapore, Singapore; 2021. pp 123-132. https://doi.org/10.1007/978-981-33-4176-0_10

Lojen G, Gojić M, Anžel I. Continuously cast Cu–Al–Ni shape memory alloy – Properties in as-cast condition. J Alloy Compd. 2013; 580: 497-505. https://doi.org/10.1016/j.jallcom.2013.06.136

Ivanić I, Kožuh S, Vračan A, Kosec B, Gojić M. SEM analysis of fracture surface of the CuAlNi shape memory alloy after heat treatment. ANNALS of Faculty Engineering Hunedoara, 2018; XVI: 183-186. https://annals.fih.upt.ro/pdf-full/2018/ANNALS-2018-1-31.pdf

Gojić M, Kožuh S, Ivanić I, Selanec M, Holjevac Grgurić T, Kosec B, Ćubela D, Beganović O. Microstructural characterization of Cu82.3Al8.3Mn9.4 shape memory alloy after rolling. Met Mater Eng. 2017; 23(3): 281-289. https://doi.org/10.30544/314

Ivanić I, Gojić M, Kožuh S, Kosec B. Microstructural and fractographic analysis of CuAlNi shape memory alloy before and after heat treatment. Defect Diffus For. 2020; 405: 100-106. https://doi.org/10.4028/www.scientific.net/ddf.405.100

Zhou L, Sohn YH. Diffusion and its Application in NiMnGa Alloys. Diffus Found. 2018; 19: 80-95. https://doi.org/10.4028/www.scientific.net/df.19.80

Mehrpouya M, Cheraghi Bidsorkhi H. MEMS applications of NiTi based shape memory alloys. Micro Nanosyst 2016; 8: 79–91. https://doi.org/10.2174/1876402908666161102151453

Martinović S, Vlahović M, Gajić-Kvaščev M, Vuksanović M, Glišić D, Volkov-Husović T. Principal component analysis of morphological descriptors for monitoring surface defects induced by thermal shock. J Eur Ceram Soc. 2021; 41(16): 423-429. https://doi.org/https://doi.org/10.1016/j.jeurceramsoc.2021.08.058

Martinovic S, Vlahovic M, Volkov-Husovic T. Deterioration characterization during thermal shock testing. Sci Sinter. 2023; 55(1): 71-80. https://doi.org/10.2298/sos2301071m

Vlahović M, Alil A, Devečerski A, Živojinović D, Volkov-Husović T. Non-destructive examination for cavitation resistance of talc-based refractories with different zeolite types intended for protective coatings. Mater 2023; 16(16): 5577. https://doi.org/10.3390/ma16165577

Martinović S, Alil A, Milićević S, Živojinović D, Volkov Husović T. Morphological assessment of cavitation caused damage of cordierite and zircon based materials using principal component analysis. Eng Fail Anal. 2023; 148(107224): 107224. https://doi.org/10.1016/j.engfailanal.2023.107224

Vuksanović MM, Gajić-Kvaščev M, Husović TV, Heinemann RJ. Advanced damage resistance monitoring procedure on the composite materials’ surface-exposed to cavitation testing. Wear. 2021; 474- 475: 203877. https://doi.org/10.1016/j.wear.2021.203877

Simic M, Alil A, Martinovic S, Vlahovic M, Savic A, Volkov-Husovic T. High temperature materials: properties, demands and applications. Hem Ind. 2020; 74(4): 273-284. https://doi.org/10.2298/hemind200421019s

Jani JM, Leary M, Subic A. Shape Memory Alloys in Automotive Applications. Appl Mech Mater. 2014; 663: 248-253. https://doi.org/10.4028/www.scientific.net/AMM.663.248

Stoeckel D. Shape memory actuators for automotive applications. Mater Eng. 1990; 11(6): 302-307. https://doi.org/10.1016/0261-3069(90)90013-a

Luchetti T, Zanella A, Biasiotto M, Saccagno A. Electrically Actuated Antiglare RearView Mirror Based on a Shape Memory Alloy Actuator. J Mater Eng Perform.; 2009; 18: 717-724. https://doi.org/10.1007/s11665-009-9487-6

Melton KN, General application of SMA’s and smart materials: In Otsuka K, Wayman CM. Eds. Shape memory materials. Cambridge, UK, Cambridge University Press, 1998. 220-239. ISBN 978-0521663847

Sofla AYN, Meguid SA, Tan KT, Yeo WK. Shape morphing of aircraft wing: Status and challenges. Mater Eng. 2010; 31(3): 1284-1292. https://doi.org/10.1016/j.matdes.2009.09.011

Icardi U, Ferrero L. Preliminary study of an adaptive wing with shape memory alloy torsion actuators. Mater Des. 2009; 30(10): 4200-4210. https://doi.org/https://doi.org/10.1016/j.matdes.2009.04.045

Peffer A, Denoyer K, Fosness E, Sciulli D. Development and transition of low-shock spacecraft release devices. In: 2000 IEEE Aerospace Conference. Proceedings Vol. 4. Big Sky MT, USA, 2000, pp. 277-284. https://doi.org/10.1109/AERO.2000.878439

Vaidyanathan R, Chiel HJ, Quinn RD. A hydrostatic robot for marine applications. Rob Auton Syst. 2000; 1-2: 103-113. https://doi.org/10.1016/S0921-8890(99)00067-6

Buehler WJ, Wang FE. A summary of recent research on the nitinol alloys and their potential application in ocean engineering. Ocean Eng. 1968; 1(1): 105-120. https://doi.org/https://doi.org/10.1016/0029-8018(68)90019-X

Ivošević Š, Rudolf R. Materials with shape memory effect for applications in maritime. Sci J Polish Nav Acad. 2019; 218(3): 25-41. https://doi.org/10.2478/sjpna-2019-0016

Ivošević Š, Vastag G, Kovač N, Majerič P, Rudolf R. A nonlinear probabilistic pitting corrosion model of Ni-Ti alloy immersed in shallow seawater. Micromachines (Basel). 2022; 13(7): 1031. https://doi.org/10.3390/mi13071031

Nespoli A, Besseghini S, Pittaccio S, Villa E, Viscuso S. The high potential of shape memory alloys in developing miniature mechanical devices: A review on shape memory alloy mini-actuators. Sensors Actuators A. 2010; 158(1): 149-160. https://doi.org/https://doi.org/10.1016/j.sna.2009.12.020

Fujita H. Studies of micro actuators in Japan. In: Proceedings 1989 Int Conf Robot Autom 2003. https://doi.org/10.1109/robot.1989.100200

Kuribayashi K. Millimeter-sized joint actuator using a shape memory alloy. Sensors and Actuators 1989; 20(1): 57-64. https://doi.org/https://doi.org/10.1016/0250-6874(89)87102-1

Caldwell DG, Taylor PM. Artificial muscles as robotic actuators. IFAC Proc Vol 1988; 1(16): 401-406. https://doi.org/10.1016/s1474-6670(17)54643-1

Loh CS, Yokoi H, Arai T. New shape memory alloy actuator: Design and application in the prosthetic hand. In: 2005 IEEE Engineering in Medicine and Biology 27th Annual Conference. Scottsdale, Shanghai. China, 2005, pp. 6900-6903 https://doi.org/10.1109/iembs.2005.1616092

Kuribayashi K. A new actuator of a joint mechanism using TiNi alloy wire. Int J Rob Res. 1986; 4(4): 47-58. https://doi.org/10.1177/027836498600400404

Harashima F, Ed. Integrated Micro-motion Systems: Micromachining, Control, and Applications: A Collection of Contributions Based on Lectures Presented at the Third Toyota Conference, Aichi, Japan, 22-25 October 1989. Amsterdam, Holand: Elsevier; 1990. ISBN 9780444884176

Mines researcher flying into eye of storm to learn more about air-sea interactions. https://www.minesnewsroom.com Accsessed June 13,2024

Tabrizikahou A, Kuczma M, Łasecka-Plura M, Noroozinejad Farsangi E, Noori M, Gardoni P, Li S. Application and modelling of Shape-Memory Alloys for structural vibration control: State-of-the-art review. Constr Build Mater. 2022; 342: 127975. https://doi.org/https://doi.org/10.1016/j.conbuildmat.2022.127975

Das J, Balasubramaniam VR, Goverdhan K, Ganapathy G. Overview of seismic monitoring and assessment of seismic hazard based on a decade of seismic events. In: Proceedings of the conference on Recent Advances in Rock Engineering, Bengaluru, India, 2016, pp. 557- 564. https://doi.org/10.2991/rare-16.2016.90

Hudyma M, Brummer R. Seismic Monitoring in Mines – Design, Operation, Tricks and Traps. Proceedings of the 1st Canada-US Rock Mechanics Symposium, Vancouver, Canada, 27-31 May 2007. Paper No ARMA-07-174 https://www.researchgate.net/ publication/291698728_Seismic_Monitoring_in_Mines_-_Design_Operation_Tricks_and_Traps

Bodaghi M, Shakeri M, Aghdam MM. Thermo-mechanical behavior of shape adaptive composite plates with surface-bonded shape memory alloy ribbons. Compos Struct. 2015; 119: 115-133. https://doi.org/10.1016/j.compstruct.2014.08.027

Kuang Y, Ou J. Self-repairing performance of concrete beams strengthened using superelastic SMA wires in combination with adhesives released from hollow fibers. Smart Mater Struct. 2008; 17: 25020-25027. https://doi.org/10.1088/0964-1726/17/2/025020

Viet N V, Zaki W. Bending model for a laminated composite cantilever beam with multiple embedded shape memory alloy layers presenting tensile-compressive asymmetry. Compos Struct. 2019; 229: 111410. https://doi.org/https://doi.org/10.1016/j.compstruct.2019.111410

Azadpour F, Maghsoudi AA. Experimental and analytical investigation of continuous RC beams strengthened by SMA strands under cyclic loading. Constr Build Mater. 2020; 239: 117730. https://doi.org/https://doi.org/10.1016/j.conbuildmat.2019.117730

Cui D, Gan B. Application of shape memory alloy in Civil Engineering. In: Proceedings of the 5th International Conference on Advanced Design and Manufacturing Engineering. Shenzhen, China, 2015, pp 86-89 https://doi.org/10.2991/icadme-15.2015.18

Yi H, Kim D, Kim Y, Kim D, Koh J, Kim M-J. 3D-printed attachable kinetic shading device with alternate actuation: Use of shape-memory alloy (SMA) for climate-adaptive responsive architecture. Autom Constr. 2020; 114: 103151. https://doi.org/https://doi.org/10.1016/j.autcon.2020.103151

Yüce İ. Shape Memory Polymers and Shape Memory Alloys: Use in Smart Textiles. Int J Dev Res. 2017; 07(11): 16730-16736. https://www.journalijdr.com/sites/default/files/issue-pdf/10761..pdf

Bartkowiak G, Dąbrowska A, Greszta A. Development of smart textile materials with shape memory alloys for application in protective clothing. Mater. 2020; 13(3): 689. https://doi.org/10.3390/ma13030689

Yoo S, Yeo J, Hwang S, Kim YH, Hur SG, Kim E. Application of a NiTi alloy two-way shape memory helical coil for a versatile insulating jacket. Mater Sci Eng A. 2008; 481-482: 662-667. https://doi.org/https://doi.org/10.1016/j.msea.2006.12.233

Bartkowiak G, Dąbrowska A, Greszta A. Development of smart textile materials with shape memory alloys for application in protective clothing. Mater 2020; 13(3): 689. https://doi.org/10.3390/ma13030689

Bartkowiak G, Dąbrowska A. Textile materials with SMA elements for active protection against heat and flame. In: 7thForum on New Materials, including the 5th International Conference “Smart and Multifunctional Materials, Structures and Systems” and the 11th International Conference “Medical Applications of New Biomaterials and Nanotechnology”. Perugia, Italy, 2016 pp. 11-16 https://doi.org/10.4028/www.scientific.net/ast.100.11

Petrini L, Migliavacca F. Biomedical applications of shape memory alloys. J Met. 2011; 2011: 501483. https://doi.org/10.1155/2011/501483

Morgan NB. Medical shape memory alloy applications—the market and its products. Mater Sci Eng A Struct Mater. 2004; 378(1-2): 16-23. https://doi.org/10.1016/j.msea.2003.10.326

Wang Y, Venezuela J, Dargusch M. Biodegradable shape memory alloys: Progress and prospects. Biomaterials. 2021; 279(121215): 121215. https://doi.org/10.1016/j.biomaterials.2021.121215

Ugrinović V, Marković M, Božić B, Panić V, Veljović D. Poly(methacrylic acid) hydrogels crosslinked by poly(ethylene glycol) diacrylate as pH-responsive systems for drug delivery applications. Hem Ind. 2023; 77(4): 235-249. https://doi.org/10.2298/hemind221228018u