Design and optimization of a packed bed scrubber for purification of waste gas containing ammonium Technical paper

Main Article Content

Abstract

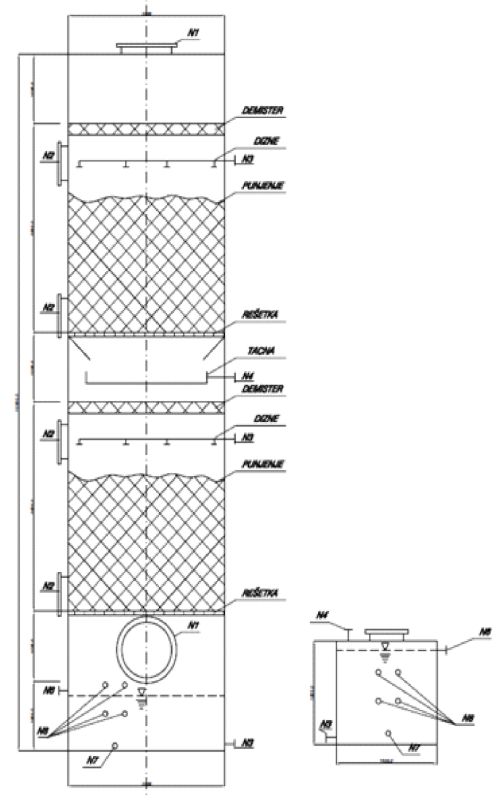

In this work, a two-stage packed bed scrubber was designed and optimized for purification of industrial waste gas containing ammonia at a concentration of 1400 mg m-3. Basic material balance equations, equilibrium data, and the generalized pressure drop correlation were used for the calculation. For the analysis of different configurations, Katmar software was utilized, which uses the generalized pressure drop correlation in order to calculate the scrubber diameter based on the allowable pressure drop and proximity to flooding conditions. It was found that optimal results are achieved in a two-stage device, using 70 vol.% sulfuric acid for chemisorption of ammonia. Pall rings, 50 mm in size and made of polypropylene, were selected as a column packing. Performances of scrubbers of three column diameters (i.e., Dc=2; 2.1 and 2.2 m) were analyzed. From the aspect of the liquid phase flow, the column diameter of 2 m provides satisfactory results. According to the packing specifications, the pressure drop through the packing layer would be about 900 Pa. It was found that the pressure gradient, and therefore the total pressure drop in the column decreases with increasing the column diameter. However, as the diameter of the column increases, the minimum flow rate of the liquid phase required to wet the packed bed increases, so the required liquid flow rate increases. Taking into account all of the analyzed process parameters, as well as the required purification degree of the waste gas, the optimal configuration of the device was proposed.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

References

Bhatia MV. Packed Tower and Absorption Design. In Cheremisinoff PN, Young RA, eds. Air Pollution Control and Design Handbook. New York, NY: Marcel Dekker; 1977. https://doi.org/10.1007/978-981-13-7488-3

Richards JR. Control of Gaseous Emissions. APTI Course 415. U.S. Environmental Protection Agency; 1995. https://www.4cleanair.org/wp-content/uploads/APTI/415combined.pdf

Srivastava RK, Jozewicz W, Singer C. SO2 scrubbing technologies. Environ Prog. 2001; 20(4): 219-28. https://doi.org/10.1002/ep.670200410

Wet Scrubber System Study. NTIS Report PB-213016; U.S. EPA, Research Triangle Park, NC, 1972. https://nepis.epa.gov/Exe/ZyNET.exe/9101LF9J.txt?ZyActionD=ZyDocument&Client=EPA&Index=Prior%20to%201976&Docs=&Query=&Time=&EndTime=&SearchMethod=1&TocRestrict=n&Toc=&TocEntry=&QField=&QFieldYear=&QFieldMonth=&QFieldDay=&UseQField=&IntQFieldOp=0&ExtQFieldOp=0&XmlQuery=&File=D%3A%5CZYFILES%5CINDEX%20DATA%5C70THRU75%5CTXT%5C00000023%5C9101LF9J.txt&User=ANONYMOUS&Password=anonymous&SortMethod=h%7C-&MaximumDocuments=1&FuzzyDegree=0&ImageQuality=r75g8/r75g8/x150y150g16/i425&Display=hpfr&DefSeekPage=x&SearchBack=ZyActionL&Back=ZyActionS&BackDesc=Results%20page&MaximumPages=1&ZyEntry=1&slide#

Joseph GTPE, Beachler DS. Scrubber System Operation Review., 2nd ed., North Carolina State University; 1998. https://www.studocu.com/es-mx/document/universidad-veracruzana/operaciones-fisicas-unitarias/design-review-of-absorbers-used-for-gaseous-pollutants-removal/10718576

Hesketh HD. Wet scrubbers. 2nd ed., New York, NY: Routledge; 2017. https://doi.org/10.1201/9780203733899

U.S. Environmental Protection Agency, 1998. Wet-Film (Packed Tower) Scrubbers. 2012; 1-15. www.yosemite.epa.gov/oaqps/eogtrain.nsf.gov

Schifftner KC, Hesketh HE. Wet scrubbers. United States: 1983. https://www.osti.gov/biblio/6626241

McCabe Wl, Smith JC, Harriot P Unit Operations of Chemical Engineering, McGraw-Hill International Editions, New York, 1993. ISBN 0-07-044844-2. https://evsujpiche.files.wordpress.com/2014/06/unit-operations-of-chemical-engineering-5th-ed-mccabe-and-smith.pdf

Strigle RE Jr. Packed Tower Design and Applications - Random and Structured Packings. 2nd ed., Houston, London, Paris, Zurich, Tokyo: Gulf Publishing Company; 1994. ISBN 0-88415-179-4. https://www.scribd.com/doc/81675448/Packed-Tower-Design-and-Applications-R-F-Strigle-1994

Phillips J. Control and pollution prevention options for ammonia emissions: VIGYAN Inc. (Technical Report), United States; 1995. https://www.osti.gov/biblio/104094

Hadlocon LJ, Manuzon RB, Zhao L. Optimization of ammonia absorption using acid spray wet scrubbers. Transactions of the ASABE. 2014; 57(2): 647-659. https://doi.org/10.13031/trans.57.10481

Ashtari AK, Majd AM, Riskowski GL, Mukhtar S, Zhao L. Removing ammonia from air with a constant pH, slightly acidic water spray wet scrubber using recycled scrubbing solution. Front Environ Sci Eng. 2016; 10; 3. https://doi.org/10.1007/s11783-016-0869-3

Piche S, Larachi F, Grandjean BPA. Flooding Capacity in Packed Towers: Database, Correlations, and Analysis. Ind. Eng Chem Res. 2001; 40: 476-487. https://doi.org/10.1021/ie000486s

Packed Column Calculator, Version 2.1, March 2010, Katmar Software, http://www.KatmarSoftware.com

Leva M. Tower Packings and Packed Tower Design. United States Stoneware Company: Akron, OH, 1953. https://babel.hathitrust.org/cgi/pt?id=mdp.39015000476294&seq=11

Eckert JS. How tower packings behave. Chem Eng. 1975; 2(8): 70-76. https://www.coursehero.com/file/p5fbd1p/Eckert-J-S-1975-How-tower-packings-behave-Chemical-Engineering-v-82-pp-70-Ellis/

Robbins L. Improve pressure drop prediction with a new correlation. Chem Eng Prog. 1991; 87(5): 87-90. ISSN 0360-7275. https://api.semanticscholar.org/CorpusID:113682503

The Pall Ring Company Ltd., UK. https://www.pallrings.co.uk/products/pall-rings-plastic/