Impact of leaching procedure on heavy metals removal from coal fly ash Original scientific paper

Main Article Content

Abstract

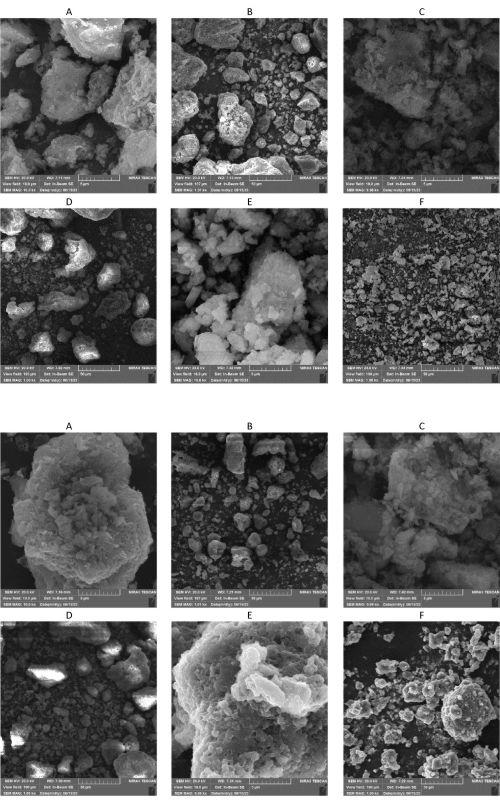

In this work, removal of heavy metals (Cr, Mn, Co, Ni, Cu, Zn, As, Cd, and Pb) from fly ash has been studied using acid leaching and wet oxidation methods. In parallel, microwave-assisted acid digestion was applied for determination of pseudo-total concentrations of heavy metals to estimate the leaching efficiency. Multivariate statistics (Pearson correlation, principal component analysis, and hierarchical cluster analysis) have shown two dominant groups of elements, depending on their characteristics and affinity towards the ash solid phase. Thus, Cr, Zn, Mn, Co, and Ni belong to the group I, while Pb, As, Cd, and Cu belong to the group II. It was demonstrated that the wet oxidation method was more suitable than acid leaching since the reduction in metal concentration was 30 to 75 % compared to 12 to 25 % obtained by acid digestion. The influence of fly ash treatment on the residue characteristics was investigated by X-ray diffractometry and scanning electron microscopy. The analyses revealed surface and structure changes of fly ash after the wet oxidation treatment. Overall, wet oxidation could be an appropriate treatment for heavy metal removal from fly ash, providing a material that could be further used, thus reducing the risk of pollution caused by the disposal of coal combustion fly ash.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

Funding data

-

Science Fund of the Republic of Serbia

Grant numbers 7743343

References

Šerović R, Jelić I, Matić B, Savić A. Utilization of solidified industrial hazardous waste in construction: A case study. Hem Ind. 2023; 77(2): 137-146 https://doi.org/10.2298/HEMIND222610001S.

Vukićević M, Popović Z, Despotović J, Lazarević L. Fly ash and slag utilization for the serbian railway substructure. Transport. 2018; 33(2): 389-396 https://doi.org/10.3846/16484142.2016.1252427.

Tasić AM, Sredović Ignjatović ID, Ignjatović LM, Ilić MA, Antić MP. Comparison of sequential and single extraction in order to estimate the environmental impact of metals from fly ash. J Serb Chem Soc. 2016; 81(9): 1081-1096 https://doi.org/10.2298/JSC160307038T.

Đorđević D, Stanković M, Krstić N, Dimitrijević V, Anastasijević N, Đorđević M, Nikolić M. Geochemical analysis of Kostolac power plant fly ash: working and living environment influence aspect. Saf Eng. 2018; 8(1): 15-20 https://doi.org/10.7562/SE2018.8.01.03.

Đolić M, Ćujić M, Stanišić T, Čičkarić D, Ristić M, Perić Grujić A. Contribution to the Serbian coal ranking and fly ash characterization using Pb isotopic ratio. Metall Mater Eng. 2022; 28(4): 675-684 https://doi.org/10.56801/MME931.

Slavković-Beškoski L, Ignjatović L, Bolognesi G, Maksin D, Savić A, Vladisavljević G, Onjia A. Dispersive Solid-Liquid Microextraction Based on the Poly(HDDA)/Graphene Sorbent Followed by ICP-MS for the Determination of Rare Earth Elements in Coal Fly Ash Leachate. Metals (Basel). 2022; 12(5): 791 https://doi.org/10.3390/met12050791.

Buha Marković JZ, Marinković AD, Savić JZ, Mladenović MR, Erić MD, Marković ZJ, Ristić MĐ. Risk Evaluation of Pollutants Emission from Coal and Coal Waste Combustion Plants and Environmental Impact of Fly Ash Landfilling. Toxics. 2023; 11(4): 396 https://doi.org/10.3390/toxics11040396.

Buha-Marković J, Marinković A, Savić J, Krstić A, Savić A, Ristić M. Health risk assessment of potentially harmful substances from fly ashes generated by coal and coal waste combustion. J Serb Chem Soc. 2023; 88(11): 1161-1173 https://doi.org/10.2298/JSC220130048M.

Petronijević N, Radovanović D, Štulović M, Sokić M, Jovanović G, Kamberović Ž, Stanković S, Stopić S, Onjia A. Analysis of the Mechanism of Acid Mine Drainage Neutralization Using Fly Ash as an Alternative Material: A Case Study of the Extremely Acidic Lake Robule in Eastern Serbia. Water (Switzerland). 2022; 14(20): 3244 https://doi.org/10.3390/w14203244.

Trivunac K, Vukčević M, Maletić M, Karić N, Pejić B, Perić-Grujić A. Waste materials as adsorbents for heavy metals removal from water: Comparative analysis of modification techniques. Tekst Ind. 2023; 71(1): 4-10 https://doi.org/10.5937/tekstind2301004T.

Wang N, Sun X, Zhao Q, Yang Y, Wang P. Leachability and adverse effects of coal fly ash: A review. J Hazard Mater. 2020; 396: 122725 https://doi.org/10.1016/j.jhazmat.2020.122725.

Bruker-AXS (2013). Crystallography Open Database for DIFFRAC.EVA. https://www.bruker.com/products/x-ray-diffraction-and-elemental-analysis/x-ray-diffraction/xrd-software/eva/cod.html

Powder Diffraction File: PDF-2 (Database), International Center for Diffraction Data (ICDD), Newtown Square, Pennsylvania, USA, 2008.

ASTM-C 618-15: Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use as a Mineral Admixture in Concrete. 2015

Moreno N, Querol X, Andrés JM, Stanton K, Towler M, Nugteren H, Janssen-Jurkovicová M, Jones R. Physico-chemical characteristics of European pulverized coal combustion fly ashes. Fuel. 2005; 84(11): 1351-1363 https://doi.org/10.1016/j.fuel.2004.06.038 .

Strzałkowska E. Morphology, chemical and mineralogical composition of magnetic fraction of coal fly ash. Int J Coal Geol. 2021; 240: 103746 https://doi.org/10.1016/j.coal.2021.103746.

Wei Q, Song W. Mineralogical and chemical characteristics of coal ashes from two high-sulfur coal-fired power plants in Wuhai, Inner Mongolia, China. Minerals 2020; 10(4): 323 https://doi.org/10.3390/min10040323.

Dahl O, Nurmesniemi H, Pöykiö R, Watkins G. Heavy metal concentrations in bottom ash and fly ash fractions from a large-sized (246 MW) fluidized bed boiler with respect to their Finnish forest fertilizer limit values. Fuel Process Technol. 2010; 91(11): 1634-1639 https://doi.org/10.1016/j.fuproc.2010.06.012.

Tang Q, Liu G, Zhou C, Sun R. Distribution of trace elements in feed coal and combustion residues from two coal-fired power plants at Huainan, Anhui, China. Fuel. 2013; 107: 315-322 https://doi.org/10.1016/j.fuel.2013.01.009.

Dai S, Zhao L, Peng S, Chou C-L, Wang X, Zhang Y, Li D, Sun Y. Abundances and distribution of minerals and elements in high-alumina coal fly ash from the Jungar Power Plant, Inner Mongolia, China. Int J Coal Geol. 2010; 81(4): 320-332 https://doi.org/10.1016/j.coal.2009.03.005.

da Silva EB, Li S, de Oliveira LM, Gress J, Dong X, Wilkie AC, Townsend T, Ma LQ. Metal leachability from coal combustion residuals under different pHs and liquid/solid ratios. J Hazard Mater. 2018; 341 (September): 66-74 https://doi.org/10.1016/j.jhazmat.2017.07.010.

Ramanathan T, Ting YP. Selection of wet digestion methods for metal quantification in hazardous solid wastes. J Environ Chem Eng. 2015; 3(3): 1459-1467 https://doi.org/10.1016/j.jece.2015.05.006.

Ramakrishna C, Thenepalli T, Nam SY, Kim C, Ahn JW. The brief review on coal origin and distribution of rare earth elements in various coal ash samples. KSEE. 2018; 27(2): 61-69 https://doi.org/10.5855/ENERGY.2018.27.2.061.

Hredzák S, Tomanec R, Matik M, Šepelák V, Václavíková M. Magnetic separation and analysis of products obtained from coal-fired power plant fly ashes of Nikola Tesla B (Serbia). J Min Met. 2006; 42 A: 55-68 https://www.jmma.tfbor.bg.ac.rs/Volumes/2006/06.pdf.

Šešlija M, Rosić A, Radović N, Vasić M, Đogo M, Jotić M. Physiproperties of fly ash and slag from the power plants. Geol Croat. 2016; 69(3): 317-324 https://doi.org/10.4154/gc.2016.26.

Tabachnick BG, Fidel SL. Using multivariate statistics. 7th ed., New York, NY: Pearson; 2018. ISBN 978-0134790541

Kaiser HF, A second generation little jiffy. Psychometrika. 1970; 35(4): 401-415 https://doi.org/10.1007/BF02291817.

Bartlett MS. A note on the multiplying factor for various chi square approximations. J R Stat Soc, B:Stat. 1954; 16: 296-298 https://doi.org/10.1111/j.2517-6161.1954.tb00174.x.