Continuous reciprocating plate and packed bed multiphase reactors in biodiesel production: Advancements and challenges Review paper

Main Article Content

Abstract

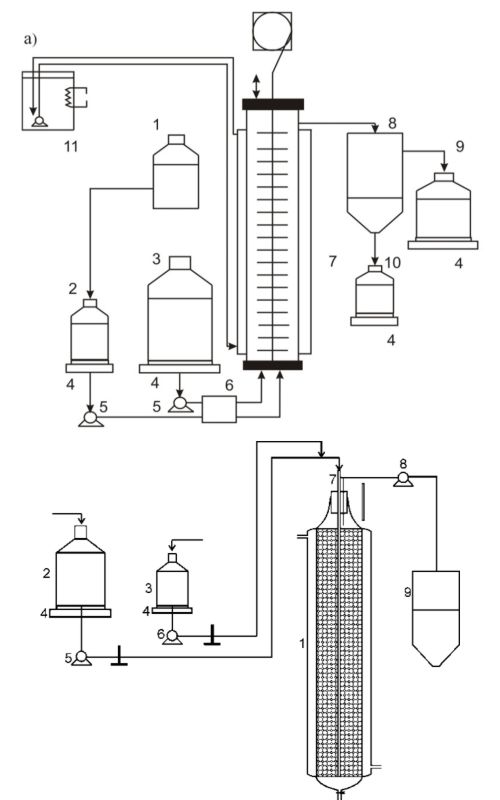

Biodiesel, a renewable and environmentally friendly alternative to conventional fossil fuels, has gained significant attention over the last two decades. Continuous production of biodiesel offers efficiency, productivity, and scalability advantages. This paper provides a concise overview of continuous reactor systems for biodiesel production, focusing on two specific systems—the reciprocating plate reactor and the packed bed reactor—subjects of the authors' extensive research. A thorough comparison of these reactors, spanning biodiesel yield, reaction kinetics, and conversion efficiency, underscores their advantages. The reciprocating plate reactor demonstrates superior mixing characteristics, which improve mass transfer and reaction kinetics. Conversely, the packed bed reactor offers a higher catalyst-to-feedstock ratio and longer residence time, enhancing conversion efficiency. Both reactors exhibit favourable performance for continuous biodiesel production. This research can contribute to understanding continuous biodiesel production using innovative reactor designs. The comparative analysis between the reciprocating plate and packed bed reactors offers valuable insights for process optimization and reactor selection based on specific requirements such as feedstock availability, reaction kinetics, and economic considerations. These insights pave the way for the implementation of sustainable and efficient biodiesel production processes in the future.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

Funding data

-

Serbian Academy of Sciences and Arts

Grant numbers F-78 -

Ministarstvo Prosvete, Nauke i Tehnološkog Razvoja

Grant numbers 451-03-47/2023-01/200133

References

Živković SB, Veljković MV, Banković-Ilić IB, Krstić IM, KonstantinovićSS, Ilić SB, Avramović JA, Stamenković OS, Veljković VB. Technological, technical, economic, environmental, social, human health risk, toxicological and policy considerations of biodiesel production and use. Renew Sust Energ Rev. 2017; 79: 222-247. https://doi.org/10.1016/j.rser.2017.05.048

Awogbemi O, Von Kallon DV, Application of tubular reactor technologies for the acceleration of biodiesel production. Bioengineering. 2022;9(8): 347. https://doi.org/10.3390/bioengineering9080347

Fonseca FAS, Vidal-Vieira JA, Ravagnani SP. Transesterification of vegetable oils: Simulating the replacement of batch reactors with continuous reactors. Bioresour Technol. 2010; 101(21): 8151-8157. https://.doi.org/10.1016/j.biortech.2010.05.077

Gopi R, Thangarasu V, Vinayakaselvi MA, Ramanathan A. A critical review of recent advancements in continuous flow reactors and prominent integrated microreactors for biodiesel production. Renew Sust Energ Rev. 2022; 154: 111869.https://doi.org/10.1016/j.rser.2021.111869

Tabatabaei M, Aghbashlo M, Dehhaghi M, Panahi HKS, Mollahosseini A, Hosseini M, Soufiyan MM. Reactor technologies for biodiesel production and processing: A review. Prog Energy Combust Sci. 2019; 74: 239-303. https://doi.org/10.1016/j.pecs.2019.06.001

Mohiddin MNB, Tan YH, Seow YX, Kansedo J, Mubarak NM, Abdullah MO, Chan YS, Khalid M, Evaluation on feedstock, technologies, catalyst and reactor for sustainable biodiesel production: A review. J Ind Eng Chem. 2021; 98: 60-81. https://doi.org/10.1016/j.jiec.2021.03.036

Ghazi ATIM, Resul MFMG, Yunus R, Yaw TCS. Preliminary design of oscillatory flow biodiesel reactor for continuous biodiesel production from Jatropha triglycerides. J Eng Sci Technol. 2008; 2(3): 138-145.

García Martín JF, Barrios CC, Alés Álvarez F-J, Dominguez Sáez A, Alvarez Mateos P. Biodiesel production from waste cooking oil in an oscillatory flow reactor. Performance as a fuel on a TDI diesel engine. Renew Energy. 2018; 125: 546-56. https://doi.org/10.1016/j.renene.2018.03.002

Highina BK, Bugaje IM, Ngala GM. Performance evaluation of continuous oscillatory baffled reactor arrangementon production of biodiesel from Jatropha oil using heterogeneous catalyst. World J Renew Energ Eng. 2014; 1: 1-7. http://www.scenrp.com/World%20Journal%20of%20Renewable%20Energy%20&%20Engineering/Current%20Issue.php

Kefas HM, Yunus R, Rashid U, Taufiq-Yap YH. Enhanced biodiesel synthesis from palm fatty acid distillate and modified sulfonated glucose catalyst via an oscillation flow reactor system. J Environ Chem Eng. 2019; 7: 102993. https://doi.org/10.1016/j.jece.2019.102993

Niyas MM, Shaija A. Biodiesel production from coconut waste cooking oil using novel solar powered rotating flask oscillatory flow reactor and its utilization in diesel engine. Therm Sci Eng Prog. 2023; 40: 101794. https://doi.org/10.1016/j.tsep.2023.101794

Zheng M, Skelton RL, Mackley MR. Biodiesel reaction screening using oscillatory flow meso reactors. Process Saf Environ Prot. 2007; 85(5): 365-371.https://doi.org/10.1205/psep07030

Son SM, Kusakabe K. Transesterification of sunflower oil in a counter-current trickle-bed reactor packed with a CaO catalyst. Chem Eng Process. 2011; 50: 650-654. https://doi.org/10.1016/j.cep.2011.04.001

Meng YL, Tian SJ, Li SF, Wang BY, Zhang MH. Transesterification of rapeseed oil for biodiesel production in trickle-bed reactors packed with heterogeneous Ca/Al composite oxide-based alkaline catalyst. Bioresour Technol. 2013; 136: 730-734. https://doi.org/10.1016/j.biortech.2013.03.081

Jindapon W, Ruengyoo S, Kuchonthara P, Ngamcharussrivichai C, Vitidsant T. Continuous production of fatty acid methyl esters and high-purity glycerol over a dolomite-derived extrudate catalyst in a countercurrent-flow trickle-bed reactor. Renew Energ. 2020; 157: 626-636. https://doi.org/10.1016/j.renene.2020.05.066

Chen G, Liu J, Yao J, Qi Y, Yan B. Biodiesel production from waste cooking oil in a magnetically fluidized bed reactor using whole-cell biocatalysts. Energy Conv Manag. 2017; 138: 556-564. https://doi.org/10.1016/j.enconman.2017.02.036

Chueluecha N, Kaewchada A, Jaree A. Biodiesel synthesis using heterogeneous catalyst in a packed-microchannel. Energy Conv Manage. 2017; 141: 145-154. https://doi.org/10.1016/j.enconman.2016.07.020

Santana HS, Tortola DS, Silva JL Jr, Taranto OP. Biodiesel synthesis in micromixer with static elements. Energy Conv Manag. 2017; 141: 28-39. https://doi.org/10.1016/j.enconman.2016.03.089

Sun P, Sun J, Yao J, Zhang L, Xu N. Continuous production of biodiesel from high acid value oils in microstructured reactor by acid-catalyzed reactions. Chem Eng J. 2010; 162: 364-370. https://doi.org/10.1016/j.cej.2010.04.064

Yamsub A, Kaewchada A, Jaree A. Pork lard conversion to biodiesel using a microchannel reactor. Korean J Chem Eng. 2014; 31:2170-2176. https://doi.org/10.1007/s11814-014-0120-5

Natarajan Y, Nabera A, Salike S, Tamilkkuricil VD, Pandian S, Karuppan M, Appusamy A. An overview on the process intensification of microchannel reactors for biodiesel production. Chem Eng Process: Process Intensif. 2019; 136: 163-176. https://doi.org/10.1016/j.cep.2018.12.008

Darnoko D, Cheryan M. Continuous production of palm methyl esters. J Am Oil Chem Soc. 2000; 77: 1269-1272. https://doi.org/10.1007/s11746-000-0199-x

Kouzu M, Fujimori A, Fukakusa R, Satomi N, Yahagi S. Continuous production of biodiesel by the CaO-catalyzed transesterification operated with continuously stirred tank reactor. Fuel Process Technol. 2018; 181: 311-317. https://doi.org/10.1016/j.fuproc.2018.10.008

Sun Y, Zhang J, Sun Z, Zhang L. Biodiesel production using calcium-based catalyst from venus shell: Modeling of startup production in an industrial reactor. Environ Prog Sustain Energy. 2019; 38(3): 1-9. https://doi.org/10.1002/ep.13053

Lodha H, Jachuck R, Suppiah Singaram S. Intensified biodiesel production using a rotating tube reactor. Energ Fuel. 2012; 26: 7037-7040. https://doi.org/10.1021/ef301235t

Chen YH, Huang YH, Lin RH, Shang NC. A continuous-flow biodiesel production process using a rotating packed bed. Bioresour Technol. 2010; 101: 668-673. https://doi.org/10.1016/j.biortech.2009.08.081

Chen YH, Huang YH, Lin RH, Shang NC, Chang CY, Chang CC, Chang CC, Chiang PC, Hu CY. Biodiesel production in a rotating packed bed using K/γ-Al2O3 solid catalyst. J Taiwan Inst Chem Eng. 2011; 42(6): 937-944. https://doi.org/10.1016/j.jtice.2011.05.007

Qiu Z, Zhao L, Weatherley L. Process intensification technologies in continuous biodiesel production. Chem Eng Process. 2010; 49: 323-330. https://doi.org/10.1016/j.cep.2010.03.005

Chen KJ, Chen YS. Intensified production of biodiesel using a spinning disk reactor. Chem Eng Process. 2014; 78: 67-72. https://doi.org/10.1016/j.cep.2014.02.009

Scares L, Franca A, Oliveira L. Feasibility of biodiesel production in a continuous flow microwave reactor with static mixing. In: 8th international conference on mechanical and aerospace engineering (ICMAE). Prague, Czech Republic: IEEE, 2017. pp. 581-585.

Thirugnanasambandham K, Sivakumar V. Investigation on biodiesel production from cotton seed oil using microwave irradiated transesterfication process. Environ Prog Sustain Energy. 2015; 34: 1229-1235. https://doi.org/10.1002/ep.12094

Ma G, Hu W, Pei W, Jiang L, Song M, Mu R. In situ heterogeneous transesterification of microalgae using combined ultrasound and microwave irradiation. Energy Conv Manag. 2015; 90: 41-46. https://doi.org/10.1016/j.enconman.2014.10.061

Avramović JM, Stamenković OS, Todorović ZB, Lazić ML, Veljković VB. Empirical modeling of ultrasound-assisted base-catalyzed sunflower oil methanolysis kinetics. CI&CEQ. 2012; 18(1): 115-127.https://doi.org/10.2298/CICEQ110705053A

Avramović JM, Radosavljević DB, Veličković AV, Stojković IJ, Stamenković OS, Veljković VB. Statistical modeling and optimization of ultrasound-assisted biodiesel production using various experimental designs. Zaštita Materijala. 2019; 60(1): 70-80. https://doi.org/10.5937/zasmat1901070A

Gogate PR, Sutkar VS, Pandit AB. Sonochemical reactors: important design and scale up considerations with a special emphasis on heterogeneous systems. Chem Eng J. 2011; 166(3): 1066-1082. https://doi.org/10.1016/j.cej.2010.11.069

Thanh LT, Okitsu K, Sadanaga Y, Takenaka N, Maeda Y, Bandow H. A two-step continuous ultrasound assisted production of biodiesel fuel from waste cooking oils: a practical and economical approach to produce high quality biodiesel fuel. Bioresour Technol. 2010; 101: 5394-5401. https://doi.org/10.1016/j.biortech.2010.02.060

Veljković VB, Avramović JM, Stamenkovi OS. Biodiesel production by ultrasound-assisted transesterification: State of the art and the perspectives. Renew Sust Energ Rev. 2012; 16: 1193-1209. https://doi.org/10.1016/j.rser.2011.11.022

Pal A, Verma A, Kachhwaha S, Maji S. Biodiesel production through hydrodynamic cavitation and performance testing. Renew Energy. 2010; 35(3): 619-624. https://doi.org/10.1016/j.renene.2009.08.027

Gole VL, Naveen K, Gogate PR. Hydrodynamic cavitation as an efficient approach for intensification of synthesis of methyl esters from sustainable feedstock. Chem Eng Process. 2013; 71: 70-76. https://doi.org/10.1016/j.cep.2012.10.006

Javadikia H, Nosrati Y, Mostafaei M, Naderloo L, Tabatabaei M. Optimization of hydrodynamic cavitations reactor efficiency for biodiesel production by response surface methods (Case study: sunflower oil). J Agric Mach. 2017; 7: 260-269.https://doi.org/10.22067/jam.v7i1.51920

https://www.hydrodynamics.com/cavitation-technology/ (Accessed April 10, 2023.)

Baroutian S, Aroua MK, Raman AAA, Sulaiman NM. A packed bed membrane reactor for production of biodiesel using activated carbon supported catalyst. Bioresour Technol. 2011; 102(2): 1095-1102. https://doi.org/10.1016/j.biortech.2010.08.076

Cao P, Dubé MA, Tremblay AY. High-purity fatty acid methyl ester production from canola, soybean, palm, and yellow grease lipids by means of a membrane reactor. Biomass Bioenergy. 2008; 32(11): 1028-1036. https://doi.org/10.1016/j.biombioe.2008.01.020

Hou R, Zhang D, Duan X, Wang X, Wang S, Sun Z. Fabrication of H3PW12O40/agarose membrane for catalytic production of biodiesel through esterification and transesterification. RSC Adv. 2016; 6: 81794-81801. https://doi.org/10.1039/C6RA17118D

Luo Q, He B, Liang M, Kong A, Li J. Continuous transesterification to produce biodiesel under HTCC/Na2SiO3/NWF composite catalytic membrane in flow-through membrane reactor. Fuel. 2017; 197: 51-57. https://doi.org/10.1016/j.fuel.2016.12.089

Petchsoongsakul N, Ngaosuwan K, Kiatkittipong W, Aiouache F, Assabum-rungrat S. Process design of biodiesel production: hybridization of ester- and transesterification in a single reactive distillation. Energy Conv Manag. 2017; 153: 493-503. https://doi.org/10.1016/j.enconman.2017.10.013

Noshadi I, Amin N, Parnas RS. Continuous production of biodiesel from waste cooking oil in a reactive distillation column catalyzed by solid heteropolyacid: Optimization using response surface methodology (RSM). Fuel. 2012; 94: 156-64. https://doi.org/10.1016/j.fuel.2011.10.018

Abduh MY, Van Ulden W, Kalpoe V, Van De Bovenkamp HH, Manurung R, Heeres HJ. Biodiesel synthesis from Jatropha curcas L. oil and ethanol in a continuous centrifugal contactor separator. Eur J Lipid Sci Technol. 2013; 115: 123-131. https://doi.org/10.1002/ejlt.201200173

Carlucci C. An overview on the production of biodiesel enabled by continuous flow methodologies. Catalysts,2022;12: 717. https://doi.org/10.3390/catal12070717

Tran DT, Chang JS, Lee DJ. Recent insights into continuous-flow biodiesel production via catalytic and non-catalytic transesterification processes. Appl Energy.2017;185: 376-409. https://doi.org/10.1016/j.apenergy.2016.11.006

Lo TC, Prochazka J. Reciprocating plate extraction columns, in Handbook of solvent extraction (Lo TC, Baird MHI, Hanson C. eds.); New York, NY: John Wiley & Sons; 1983. pp. 373-389. ISBN 0-471-04164-5.

Nikolić LB, Veljković VB, Skala DU. Axial dispersion of the liquid flow in a Karr reciprocating plate column. Hem Ind. 2001; 55: 249-254. https://doi/10.2298/JSC0407581N

Aleksić M, Veljković VB, Banković-Ilić IB, Lazić ML, Skala DU. Uticaj Rašigovih prstenova i reoloških osobina tečnosti na promenu pritiska na dnu kolone sa vibracionom mešalicom. Hem Ind. 2002; 56:409-414. https://doi.org/10.2298/HEMIND0210409A (in Serbian).

Aleksić M, Veljković VB, Banković-Ilić IB, Lazić ML, Skala DU. Uticaj Rašigovih prstenova i reoloških osobina tečnosti na promenu pritiska na dnu kolone sa vibracionom mešalicom. Hem Ind. 2003; 57: 107-113. https://doi.org/10.2298/HEMIND0210409A (in Serbian).

Banković-Ilić I, Veljković V, Skala D. Gas holdup in a three phase reactors of the bubble column type. Hem Ind. 1994; 48: 397-402.

Banković-Ilić IB, Veljković VB, Lazić ML, Skala DU. Power consumption and gas holdup in a gas-liquid reciprocating plate column. Chem Eng Comm. 1995; 134: 17-32. https://doi.org/10.1080/00986449508936320.

Banković-Ilić I, Veljković V, Skala D. Hidrodinamičke i masenoprenosne karakteristike kolone sa vibracionom mešalicom za sisteme gas-tečnost i gas-tečnost-čvrsta faza - monografija. Leskovac: Tehnološki fakultet; 2009. ISBN 978-86-82367-80-2 (in Serbian)

Hafez M, Baird MHI. Power consumption in a reciprocating plate column. Trans Inst Chem Eng. 1978; 56: 229-238.

Naseva OS, Stamenković IS, Banković-Ilić IB, Lazić ML, Veljković VB, Skala DU. Sadržaj gasa u bioreaktoru sa vibracionom mešalicom - tečna faza je njutnovski fluid. Hem Ind. 2002; 56: 198-203. https://doi.org/10.2298/HEMIND0205198N (in Serbian)

Skala DU, Veljković VB, Janjić VV, Lazić M, Banković-Ilić IB. Gas holdup in a gas-liquid-solid reciprocating plate column. Can J Chem Eng. 1993; 71: 817-820. https://doi.org/10.1002/cjce.5450710521

Vasić Lj, Banković-Ilić IB, Lazić ML, Veljković VB, Skala DU. Sadržaj gasa u koloni sa vibracionom mešalicom prečnika 16,6 cm. Hem ind. 2005; 59: 263-266. https://doi.org/10.2298/HEMIND0510263V

Veljković V, Skala D. Hydrodynamic investigation of gas-liquid contacting in a reciprocating plate column. Can J Chem Eng. 1986; 64: 906-914. https://doi.org/10.1002/cjce.5450640604

Banković-Ilić IB, Veljković VB, Lazić ML, Skala DU. Mass transfer in a multiphase vibration column. I The volumetric mass transfer coefficient. Chem Ind. 2001; 55(9): 376-382

Banković-Ilić IB, Veljković VB, Lazić ML, Skala DU. Mass transfer in a multiphase vibration column. II. Interfacial area. Chem Ind. 2001; 55(9): 383-388

Lounes M, Thibault J. Mass transfer in a reciprocating plate bioreactor. Chem Eng Commun. 1994; 127: 169-189. https://doi.org/10.1080/00986449408936231.

Sundaresan A, Varma YBG. Interfacial area and mass transfer in gas-liquid cocurrent upflow and countercurrent flow in reciprocating plate column. Can J Chem Eng. 1990; 68: 951-958. https://doi.org/10.1002/cjce.5450680610

Rama Rao NV, Baird MHII. Gas-liquid mass transfer in a 15 cm diameter reciprocating plate column. J Chem Technol Biotech. 2003;78: 134-137. https://doi.org/10.1002/jctb.704

Skala D, Veljković V. Mass transfer characteristics in a gas-liquid reciprocating plate column. I. Liquid phase volumetric mass transfer coefficient. Can J Chem Eng. 1988; 66: 192-199. https://doi.org/10.1002/cjce.5450660203

Vasić Lj, Banković-Ilić IB, Lazić ML, Veljković VB, Skala DU. Oxygen mass transfer in a 16.6 i.d. multiphase reciprocating plate column. J Serb Chem Soc. 2007; 72: 523-531. https://doi.org/10.2298/JSC0705523V

Veljković V, Skala D. Mass transfer characteristics in a gas-liquid reciprocating plate column. II. Interfacial area. Can J Chem Eng. 1988; 66: 200-210. https://doi.org/10.1002/cjce.5450660203

Banković-Ilić IB, Todorović ZB, Avramović JM, Veličković AV, Veljković VB. The effect of tetrahydrofuran on the base-catalyzed sunflower oil methanolysis in a continuous reciprocating plate reactor. Fuel Process Technol. 2015; 137: 339-350. http://dx.doi.org/10.1016/j.fuproc.2015.03.023

Stamenković I, Stamenković O, Todorović Z, Banković -Ilić I, Lazić M, Veljković V, et al. The production of fatty acid methyl esters by a continuous base catalyzed methanolysis of sunflower oil. In: The Proceedings of the 1st Conference of the Sustainable Development And Climate Changes. Niš, Serbia, 2008. p. 251-255.

Stamenković IS, Banković-Ilić IB, Jovanić PB, Veljković VB, Skala D. Hydrodynamics of a cocurrent upflow liquid-liquid reciprocating plate reactor for homogeneously base-catalyzed methanolysis of vegetable oils. Fuel 2010; 89: 3971-3984. http://www.doi:10.1016/j.fuel.2010.06.026

Stamenković I, Stamenković O, Banković-Ilić I, Todorović Z, Lazić M, Veljković V, Skala D. Production of fatty acid esters by continuous alcoholysis of vegetable oils. Serbian patent RS 52398 B, 2013 (in Serbian)

Hafez M, Prochazka J. The dynamic effects in a vibrating plate and pulsed extractors I. Theory and experimental technique. Chem Eng Sci. 1974; 29: 1745-1753. https://doi.org/10.1016/0009-2509(74)87033-8

Jealous AC, Johnson HF. Power requirements for pulse generation in pulse column. Ind Eng Chem. 1955; 47: 1159-1166. https://doi.org/10.1021/ie50546a021

Stamenković I. Kontinualna homogena bazno katalizovana alkoholiza biljnih ulja u reaktoru sa vibracionom mešalicom. Doktorska disertacija, Univerzitet u Nišu, Tehnološki fakultet, Leskovac; 2014 (in Serbian).

Rama Rao NV, Srinivas NS, Varma YBG. Dispersed phase holdup and drop size distributions in reciprocating plate columns. Can J Chem Eng. 1983; 61: 168-177. https://doi.org/10.1002/cjce.5450610204

Stamenković OS, Lazić ML, Todorović ZB, Veljković VB, Skala DU. The effect of agitation intensity on alkali-catalyzed methanolysis of sunflower oil. Bioresour Technol. 2007; 98: 2688-2699. https://doi.org/10.1016/j.biortech.2006.09.024

Banković-Ilić IB, Veljković VB, Lazić ML, Skala DU. Mass transfer in a multiphase vibration column. I. The volumetric mass transfer coefficient. Hem. Ind. 2001; 55: 376-382

Baird MHI, Rama Rao NV. Characteristics of a countercurrent reciprocating plate bubble column. II Axial mixing and mass transfer. Can J Chem Eng. 1988; 66: 222-231. https://doi.org/10.1002/cjce.5450660206

Sundaresan A, Varma YBG. Yang NS, Shen ZQ, Chen BH, McMillan AF. Axial mixing and mass transfer in gas-liquid Karr columns. Ind Eng Chem Proc Des Dev. 1986; 25: 776-780. https://doi.org/10.1021/i200034a031

Yang NS, Shen ZQ, Chen BH, Mc Millan AF. Pressure drop, gas holdup and interfacial area for gas-liquid contact in Karr-columns. Ind Eng Chem Pro. Des Dev. 1986; 25: 660-664. https://doi.org/10.1021/i200034a011

Miladinović MR, Stojković IJ, Veličković AV, Stamenković OS, Banković-Ilić IB, Veljković VB. Optimization and kinetic modeling of waste lard methanolysis in a continuous reciprocating plate reactor. Chin J Chem Eng. 2019; 27: 2481-2490. https://doi.org/10.1016/j.cjche.2019.02.019

Xu W, Gao L, Wang S, Xiao G. Biodiesel production from soybean oil in a membrane reactor over hydrotalcite based catalyst: An optimization study. Energ Fuels. 2013; 27:6738-6742. https://doi.org/10.1021/ef401823z

Xu W, Gao L, Xiao G. Biodiesel production optimization using monolithic catalyst in a fixed-bed membrane reactor. Fuel. 2015; 159: 484-490. https://doi.org/10.1016/j.fuel.2015.07.017

Hernández-Montelongo R, García-Sandoval JP, Dochain D, Gonz A. Biodiesel production in a continuous packed bed reactor with recycle: A modeling approach for an esterification system. Renew Energy. 2018; 116: 857-865. https://doi.org/10.1016/j.renene.2017.09.030

Chueluecha N, Kaewchada A, Jaree A. Enhancement of biodiesel synthesis using co-solvent in a packed-microchannel. J Ind Eng Chem. 2017; 51: 162-171. https://doi.org/10.1016/j.jiec.2017.02.028

Perego C, Peratello S. Experimental methods in catalytic kinetics. Catal Today. 1999; 52: 133-145.

Zahan KA, Kano M. Technological progress in biodiesel production: An Overview on different types of reactors. Energy Procedia. 2019; 156: 452-457. (https://doi.org/10.1016/j.egypro.2018.11.086

Marinković DM, Miladinović MR, Avramović JM, Krstić IB, Stanković MV, Stamenković OS, Jovanović DM, Veljković VB. Kinetic modeling and optimization of sunflower oil methanolysis catalyzed by spherically-shaped CaO/γ -Al2O3 catalyst. Energy Conv Manag. 2018; 163: 122-133. https://doi.org/10.1016/j.enconman.2018.02.048

Miladinović MR, Stamenković OS, Veljković VB, Skala DU. Continuous sunflower oil methanolysis over quicklime in a packed-bed tubular reactor. Fuel. 2015; 154: 301-307. https://doi.org/10.1016/j.fuel.2015.03.057

Hashemzadeh Gargari M, Sadrameli SM. Investigating continuous biodiesel production from linseed oil in the presence of a Co-solvent and a heterogeneous based catalyst in a packed bed reactor. Energy. 2018; 148: 888e895. https://doi.org/10.1016/j.energy.2018.01.105

Melero JA, Bautista LF, Iglesias J, Morales G, Sánchez-vazquez R. Production of biodiesel from waste cooking oil in a continuous packed bed reactor with an agglomerated Zr-SBA-15/bentonite catalyst. Applied Catal B. Environ. 2014; 145: 197-204. https://doi.org/10.1016/j.apcatb.2013.02.050

Ren Y, He B, Yan F, Wang H, Cheng Y, Lin L, Feng Y, Li J. Continuous biodiesel production in a fixed bed reactor packed with anion-exchange resin as heterogeneous catalyst. Bioresour Technol. 2012; 113: 19-22. https://doi.org/10.1016/j.biortech.2011.10.103

Zabaruddin NH, Mohamed NH, Abdullah LC, Tamada M, Ueki Y, Seko N, Choong TSY. Palm oil-based biodiesel synthesis by radiation-induced kenaf catalyst packed in a continuous flow system. Ind Crops Prod. 2019; 136: 102-109. https://doi.org/10.1016/j.indcrop.2019.04.069

Buasri A, Loryuenyong V. Continuous production of biodiesel from rubber seed oil using a packed bed reactor with BaCl2 impregnated CaO as catalyst. 2018; 13(2): 320-330. https://doi.org/10.9767/bcrec.13.2.1585.320-330

Sakthivel S, Halder S, Gupta PD. Optimization of process variables for production of biodiesel in packed bed reactor using response surface methodology. Int J Ambient Energy. 2013; 34: 83-91. https://doi.org/10.1080/01430750.2012.740422

Ketcong A, Meechan W, Naree T, Seneevong I. Production of fatty acid methyl esters over a limestone-derived heterogeneous catalyst in a fixed-bed reactor. J Ind Eng Chem. 2014; 20(4): 1665-1671. https://doi.org/10.1016/j.jiec.2013.08.014

Miladinović MR, Stamenković OS, Banković PT, Milutinović AD, Jovanovic DM, Veljković VB. Modeling and optimization of sunflower oil methanolysis over quicklime bits in a packed bed tubular reactor using the response surface methodology. Energy Conv Manag. 2016; 130: 25-33. https://doi.org/10.1016/j.enconman.2016.10.020

Co CET, Tan MC, Diamante JAR, Yan LRC, Tan RR, Razon LF. Internal mass-transfer limitations on the transesterification of coconut oil using an anionic ion exchange resin in a packed bed reactor. CatalToday. 2011; 174(1): 54-58. https://doi.org/10.1016/j.cattod.2011.02.065

Buasri A, Chaiyut N, Loryuenyong V, Rodklum C, Chaikwan T, Kumphan N. Continuous process for biodiesel production in packed bed reactor from waste frying oil using potassium hydroxide supported on Jatropha curcas fruit shell as solid catalyst. Appl Sci. 2012; 2: 641-653. https://doi.org/10.3390/app2030641

Akkarawatkhoosith N, Kaewchada A, Ngamcharussrivichai C, Jaree A. Biodiesel production via interesterification of palm oil and ethyl acetate using ion-exchange resin in a packed-bed reactor. BioEnergy Res. 2020; 13: 542-551. https://doi.org/10.1007/s12155-019-10051-4

Díaz L, Escalante D, Rodríguez KE, Kuzmina Y, Gonz LA. Response surface methodology for continuous biodiesel production from Jatropha curcas oil using Li/pumice as catalyst in a packed-bed reactor assisted with diethyl ether as cosolvent. Chem Eng Process: Process Intensif. 2022; 179: 109065. https://doi.org/10.1016/j.cep.2022.109065

Zabaruddin NH, Abdullah LC, Mohamed NH, Choong TSY. Optimization using response surface methodology (RSM) for biodiesel synthesis catalyzed by radiation-induced kenaf catalyst in packed-bed reactor. Processes. 2020; 8: 1289. https://doi.org/10.3390/pr8101289

Sulaiman S, Mohamed A, Raja S, Shah S, Ehsan R. Potash derived from orange peel supported on PVA as a heterogeneous catalyst for biodiesel production in the packed bed reactor. Appl Nanosci. 2022; 12(12): 3747-3754. https://doi.org/10.1007/s13204-022-02367-z

Talha NS, Sulaiman S. In situ transesterification of solid coconut waste in a packed bed reactor with CaO / PVA catalyst. Waste Manag. 2018; 78: 929-937. https://doi.org/10.1016/j.wasman.2018.07.015

Zik N, Sulaiman S, Jamal P. Biodiesel production from waste cooking oil using calcium oxide/nanocrystal cellulose / polyvinyl alcohol catalyst in a packed bed reactor. Renew Energy. 2020; 155: 267-277. https://doi.org/10.1016/j.renene.2020.03.144