Material hold-up on inert particles in fluidized bed dryer Original scientific paper

Main Article Content

Abstract

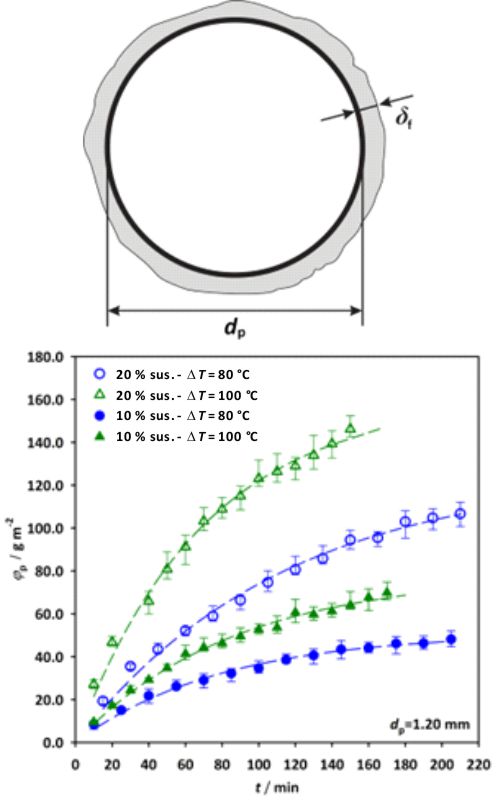

In this paper the influence of process parameters on the material hold-up in a fluidized bed dryer with inert particles was investigated. The experiments were performed in a pilot-scale dryer with a cylindrical column 0.215 m in diameter and 1.2 m height, with glass spheres of diameters dp = 1.20 mm and 1.94 mm as inert particles. The material used for drying was NaHCO3 slurry of two different concentrations, 10 and 20 wt.%. Dynamics of the material hold-up was determined for four different drying temperatures, in the range from 60 to 120 °C by taking the samples of coated particles during the drying process and measuring the mass with and without the coated material film. The obtained results showed strong positive dependence of the material hold-up on the initial slurry concentration as well as on the drying temperature. The rate of the material film coating formation is quicker at higher drying temperatures.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

Funding data

-

Ministarstvo Prosvete, Nauke i Tehnološkog Razvoja

Grant numbers 451-03-47/2023-01/200026;451-03-47/2023-01/200135

References

Mujumdar AS. Handbook of Industrial Drying. 4th ed., New York, NY: Marcel Dekker; 2014 https://doi.org/10.1201/b17208.

Kudra T., Mujumdar AS. Advanced Drying Technologies. 2nd ed., New York, NY: Marcel Dekker; 2009. ISBN 9781420073874.

Romankov PG. Drying. In: Davidson JF, Harrison D, eds. Fluidization. London: Academic Press; 1971:569-598. ISBN 0122055500.

Hadžismajlović DžE, Povrenović DS, Grbavčić ŽB, Vuković DV, Littman HA. Spout-Fluid Bed Drier for Dilute Solutions Containing Solids. In: Grace JR, Shemilt LW, Bergougnou MA, eds. Fluidization VI. New York, NY: Engineering Foundation; 1989:277-283. ISBN 0816904596, 9780816904594.

Grbavcic ZB, Arsenijevic ZLJ, Garic-Grulovic RV. Drying of slurries in fluidized bed of inert particles. Drying Technol. 2004; 22:1793-1812. https://doi.org/10.1081/DRT-200032742.

Đuriš MM, Kaluđerović Radoičić TS, Jaćimovski DR, Arsenijević ZLJ. High Efficiency Disperse Dryer - an innovative process for drying of solutions, suspensions and pastes in a fluidized bed of inert particles. Hem Ind. 2019; 73:213-222. https://doi.org/10.2298/HEMIND190626021D.

Grbavcic ZB, Arsenijevic ZLJ, Garić-Grulovic RV. Drying of Suspension and Pastes in Fluidized Bed Inert Particles. J Serb Chem Soc. 2000; 65(12):963-975. https://www.shd.org.rs/JSCS/Vol65/No12-Pdf/JSCS12-13.pdf.

Arsenijevic ZLJ, Grbavcic ZB, Garic-Grulovic RV. Drying of Suspensions in the Spouted Bed with Draft Tube. Can J Chem Eng. 2004; 82(3):450-464. https://doi.org/10.1002/cjce.5450820305.

Arsenijevic ZLJ, Grbavcic ZB, Garic-Grulovic RV. Drying of Solutions and Suspensions in the Modified Spouted Bed with Draft Tube. Thermal Science. 2002; 6(2):47-70. https://doi.org/10.2298/TSCI0202047A.

Arsenijevic ZLJ, Grbavcic ZB, Garic-Grulovic RV. Prediction of the particle circulation rate in the draft tube spouted bed suspension dryer. J Serb Chem Soc. 2006; 71(4):401-412. https://doi.org/10.2298/JSC0604401A.

Arsenijevic ZLJ, Grbavcic ZB, Garic-Grulovic RV. The Material Hold-up and Residence Time in Fluidized Bed of Inert Particles Slurry Dryer. In: Proceedings of 5th South East European Symposium on Research, Development and Implementation of New Energy Efficient and Ecologically Acceptable Technologies Applied to Energy Production, Chemical and Environmental Engineering. Sunny Beach, Bulgaria, 2005, pp. 83-94.

Kaluđerović Radoičić TS, Đuriš MM, Arsenijević ZLJ. Drying Of Suspensions And Solutions In Fluidized Bed Of Inert Particles – Material Hold-Up And Energy Efficiency Study. Annals of the Faculty of Engineering Hunedoara – International Journal of Engineering 202; XVIII(1): 137-142. https://annals.fih.upt.ro/pdf-full/2020/ANNALS-2020-1-20.pdf.

Majumder P, Deb B, Gupta R, Sablani SS. A comprehensive review of fluidized bed drying: Sustainable design approaches, hydrodynamic and thermodynamic performance characteristics, and product quality. Sustain. Energy Technol Assess. 2022. 53: 102643. https://doi.org/10.1016/j.seta.2022.102643.

Tatemoto Y, Mizukoshi R, Ehara W, Ishikawa E. Drying characteristics of food materials injected with organic solvents in a fluidized bed of inert particles under reduced pressure. J Food Eng. 2015; 158: 80–85. https://doi.org/10.1016/j.jfoodeng.2015.03.006.

Kanga DH, Kimb S, Chunb WP, Lee DH. Drying characteristics of fine powders in an inert medium circulating fluidized bed with binary inert media. J Ind Eng Chem. 2017; 45: 266–276. https://doi.org/10.1016/j.jiec.2016.09.034.

Tasirin SM, Puspasari I, Lun AW, Chai PV, Lee WT. Drying of kaffir lime leaves in a fluidized bed dryer with inert particles: Kinetics and quality determination. Ind Crops Prod. 2014. 61:19–201. https://doi.org/10.1016/j.indcrop.2014.07.004.

Barros JPAA, Ferreira MC, Freire JT. Spouted bed drying on inert particles: Evaluation of particle size distribution of recovered, accumulated and elutriated powders. Drying Technol. 2020; 38(13): 1709-1720. https://doi.org/10.1080/07373937.2019.1656644.

Huang D, Huang W, Huang S, Zhou F, Gong G, Li L, Sunden B. Applications of spouted bed technology in the drying of food products. Drying Technol. 2023. 182: 114880. https://doi.org/10.1016/j.lwt.2023.114880.

Arsenijević Z., Sušenje suspenzija u industriji, Zadužbina Andrejević, Biblioteka Dissertatio, str. 1-100, Beograd, 2008. ISBN 978-86-7244-720-0 (in Serbian)