Combustion of waste solids in a fluidized bed to generate sustainable energy Original scientific paper

Main Article Content

Abstract

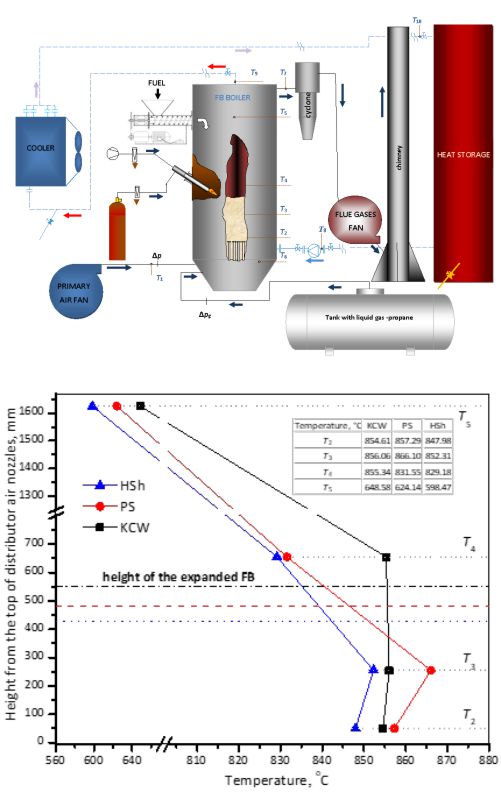

Exploring alternative options to address the impending global energy crisis while taking environmental concerns and climate change mitigation into account and addressing the skyrocketing energy demand has become urgently essential. This need is further highlighted by the Republic of Serbia's significant reliance on imported energy sources and its energy sector's strategy focus, which implies the rational use of energy resources, use of RES, and waste management with satisfying environmental regulations. The use of low-calorific and waste materials in conjunction with fluidized bed combustion (FBC) technology is the method to achieve all of the above goals synergistically. This paper presents experimental results of the combustion of several solid wastes (Kolubara's coal mining waste, paper sludge and hazelnut shells), conducted in an industrial demonstration and experimental bubbling FB boiler (capacity up to 500 kW). Burning these wastes has a variety of advantages, including recovering substantial energy remaining in them and minimizing overall waste volumes. The furnace temperature distribution, the flue gas composition at the furnace exit, and other combustion parameters of the tested fuels are given. Based on these results, an evaluation of FB combustion of waste fuels and the possibility of utilization of their energy potential is given.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

Funding data

-

Ministarstvo Prosvete, Nauke i Tehnološkog Razvoja

Grant numbers 451-03-66/2024-03/200017 -

Science Fund of the Republic of Serbia

Grant numbers 2929

References

Leckner B. Fluidized Bed Combustion. In: Reference Module in Chemistry, Molecular Sciences and Chemical Engineering. J. Reedijk (Ed.), Elsevier; 2016:

Mladenović MR. Research of thermomechanical proces during decomposition of high density liquid fuel in the fluidized bed (in Serbian), Ph.D. Thesis, University of Belgrade, Faculty of Mechanical Engineering, 2013.

Grubor BD, Dakić DV, Nemoda SD, Mladenović MR, Paprika MJ, Oka SN. Research of the fluidized bed combustion in the laboratory for thermal engineering and energy: Part A: Achievements in targeted fundamenal research. Therm Sci. 2019; 23: S1637-S1653 https://dx.doi.org/10.2298/TSCI180725289G.

Ministry of Agriculture, Forestry and Water Management of the Republic of Serbia, Information on hazelnuts, 2019, http://www.minpolj.gov.rs/download/informacija-o-lesniku-2019/

Rocha S, Candia O, Valdebenito F, Flavio Espinoza-Monje J, Azócar L. Biomass quality index: Searching for suitable biomass as an energy source in Chile. Fuel. 2020; 264: 116820 https://doi.org/10.1016/j.fuel.2019.116820.

Mladenović MR, Dakić DV, Nemoda SĐ, Paprika MJ, Komatina MS, Repić BS, Erić AM. The combustion of biomass - The impact of its types and combustion technologies on the emission of nitrogen oxide. Hem Ind. 2016; 70: 287-298 https://dx.doi.org/10.2298/HEMIND150409033M.

Mladenović M, Nemoda S, Dakić D, Milijana P, Đurović D, Repić B. Mogućnosti sagorevanja kontaminirane zrnaste biomase i drugih ostataka poljoprivredne proizvodnje u fluidizovanom sloju. Cont. Agr. Engng. 2013; 39: 213-220

ISO 1822:2015, Solid Biofuels - Determination of Ash Content, International Organization for Standardization (2015)

ISO 18134-1:2015, Solid Biofuels - Determination of Moisture Content - Oven Dry Method - Total Moisture - Reference Method (2015)

ASTM D7582-12: Standard test methods for proximate analysis of coal and coke by macro thermogravimetric analysis (2012)

ISO 16948: 2015 Solid Biofuels - Determination of Total Content of Carbon, Hydrogen and Nitrogen (2015)

ASTM D5373-14: Standard test methods for determination of carbon, hydrogen and nitrogen in analysis samples of coal and carbon in analysis samples of coal and coke (2014)

ASTM D5016-08: Standard test method for total sulfur in coal and coke combustion residues using a high-temperature tube furnace combustion method with infrared absorption (2008)

ASTM D3176-09: Standard practice for ultimate analysis of coal and coke (2009)

ISO 540:2008, Hard coal and coke – Determination of ash fusibility (2008)

SRPS EN ISO 21404:2020, Solid biofuels - Determination of ash melting behaviour

Demirbaş A. Fuel Characteristics of Olive Husk and Walnut, Hazelnut, Sunflower, and Almond Shells. Energy Sources. 2002; 24: 215-221 https://doi.org/10.1080/009083102317243601.

Bakisgan C, Dumanli AG, Yürüm Y. Trace elements in Turkish biomass fuels: Ashes of wheat straw, olive bagasse and hazelnut shell. Fuel. 2009; 88: 1842-1851 https://doi.org/10.1016/j.fuel.2009.04.[027.

ISO 1953:1994: Hard Coals - Size Analysis (1994)

SRPS B.H8.340:1988, Determination of bulk density in a small container

Yin, C., 5 - Biomass co-firing, in Biomass Combustion Science, Technology and Engineering, L. Rosendahl, Editor. 2013, Woodhead Publishing. p. 84-105. https://doi.org/10.1533/9780857097439.2.84

Mladenović MR, Dakić DV, Nemoda SDJ, Mladenović RV, Erić AM, Repić BS, Komatina MS. Combustion of low grade fractions of Lubnica coal in fluidized bed. Therm Sci. 2012; 16: 297-311 https://dx.doi.org/10.2298/TSCI1201297M.

Regulation on limit values of emissions of pollutants into the air from combustion plants ("Official Gazette of RS", no. 6/2016 and 67/2021),

Caillat, S. and E. Vakkilainen, 9 - Large-scale biomass combustion plants: an overview, in Biomass Combustion Science, Technology and Engineering, L. Rosendahl, Editor. 2013, Woodhead Publishing. p. 189-224. https://doi.org/10.1533/9780857097439.3.189

Moradian, F. (2016) Ash Behavior in Fluidized-Bed Combustion and Gasification of Biomass and Waste Fuels : Experimental and Modeling Approach. PhD dissertation. Högskolan i Borås. Available at: https://urn.kb.se/resolve?urn=urn:nbn:se:hb:diva-9563

Mladenović M, Paprika M, Marinković A. Denitrification techniques for biomass combustion. Renew Sustain Energy Rev. 2018; 82: 3350-3364 https://dx.doi.org/10.1016/j.rser.2017.10.054.

Baker CGJ, McKenzie KA. Energy Consumption of Industrial Spray Dryers. Drying Technol. 2005; 23: 365-386 https://doi.org/10.1081/DRT-200047665.

Oka S. Fluidized Bed Combustion, (Ed.), CRC Press; 2003.