Rubbing stability of printed innovative paper substrates with cereal straw pulp Original scientific paper

Main Article Content

Abstract

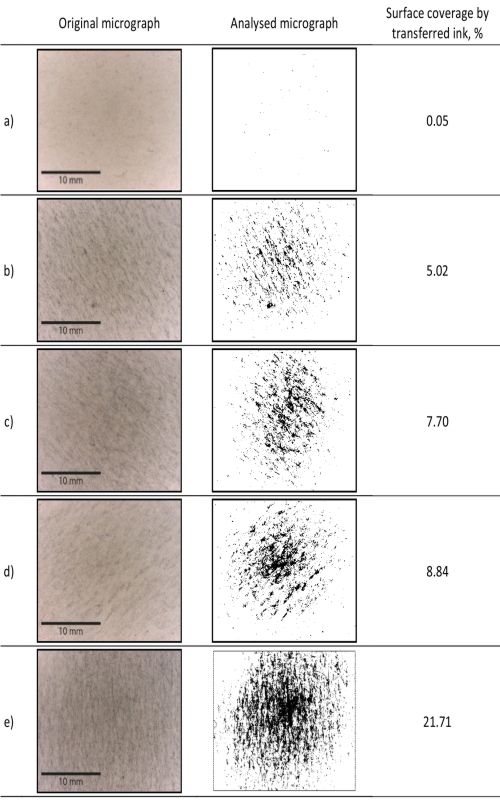

Paper is one of the most important materials for packaging and the demand for it is constantly increasing. The printing and packaging industries are researching alternative sources of fibre, to produce more environmentally friendly paper without compromising quality. As a packaging material, paper must meet high strength requirements, and it must have acceptable surface properties to preserve the printing quality. The production of paper made from pulp of recycled fibre reinforced with virgin straw fibre and the evaluation of the print quality on such papers are two objectives of this research. The straw pulp used for this purpose was obtained from three cereal crops: wheat, barley, and triticale. The paper produced was printed using five printing techniques. The rubbing stability was evaluated by the difference in colour and reflectance spectra before and after performing rub tests and a comparison was made for the best interaction of paper and ink determined by the printing technique. For the prints with the highest colour difference after the rub test, the surface of the rub test receptor (uncoated recycled paper) was examined for signs of ink transfer during the test and the areas of transferred ink coverage were calculated on their processed microscopic images.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

Funding data

-

Hrvatska Zaklada za Znanost

Grant numbers UIP-2017-05-2573

References

Marinova V. Trends in Packaging Sector. Izvestia Journal of the Union of Scientists - Varna. Economic Sciences Series. 2021; 10(1): 3-13. https://doi.org/10.36997/IJUSV-ESS/2021.10.1

Petljak K, Naletina D, Bilogrević K. Considering ecologically sustainable packaging during decision-making while buying food products. Economics of Agriculture. 2019; 66(1): 107-126. https://doi.org/10.5937/ekoPolj1901107P

Asim Z, Shamsi IRA, Wahaj M, Raza A, Abul Hasan S, Siddiqui SA, Aladresi A, Sorooshian S, Seng Teck T. Significance of Sustainable Packaging: A Case-Study from a Supply Chain Perspective. Applied System Innovation. 2022; 5(6):117. https://doi.org/10.3390/asi5060117

Oloyede OO, Lignou S. Sustainable Paper-Based Packaging: A Consumer’s Perspective. Foods. 2021; 10(5):1035. https://doi.org/10.3390/foods10051035

Parkinson L. Associations report European packaging recycling rates, Food packaging forum, 2022. https://www.foodpackagingforum.org/news/associations-report-european-packaging-recycling-rates Accessed April 27, 2023.

Liu Z, Wang H, Hui L. Pulping and Papermaking of Non-Wood Fibers, InTech 2018, https://www.intechopen.com/chapters/62223, Accessed April 27, 2023. http://dx.doi.org/10.5772/intechopen.79017

Adamopoulos S, Oliver JV. Fiber Composition of Packaging Grade Papers as determined by the Graff “C” Staining Test. Wood and Fiber Science. 2006;38(4):567-575.

Adamopoulos S, Martinez E, Ramirez D. Characterization of packaging grade papers from recycled raw materials through the study of fibre morphology and composition. Global NEST Journal. 2013; 9(1):20-28. https://doi.org/10.30955/gnj.000384

Hubbe MA, Venditti RA, Rojas OJ. What happens to cellulosic fibers during papermaking and recycling? A review. BioResources. Published online November 2007:739-788. https://doi.org/10.15376/biores.2.4.739-788

ISO 5269-2, Pulps — Preparation of laboratory sheets for physical testing — Part 2: Rapid-Köthen method, 2004

Fang G, Shen K. Wheat Straw Pulping for Paper and Paperboard Production. In: Fahad S, Basir A, Adnan M eds. Global Wheat Production. inTechOpen 2018. http://dx.doi.org/10.5772/intechopen.77274

Sood YV, Kapoor SK. Modified soda pulping of wheat straw-(Triticum volgare). IPPTA. 1984; 21:1-6.

Plazonić I, Bates I, Barbarić-Mikočević Z. The Effect of Straw Fibers in Printing Papers on Dot Reproduction Attributes, as Realized by UV Inkjet Technology. BioResources. 2016;11(2): 5033–5049. https://doi.org/10.15376/biores.11.2.5033-5049

Zhou WH, He BH, Zhang CX, Han Y. Analysis on Ink Layer Rub Resistance for Coated Paper Prints. Advanced Materials Research. 2011; 380:173-178. https://doi.org/10.4028/www.scientific.net/amr.380.173

Koivula H, Gane P, Toivakka M. Influence of ink components on print rub. Nordic Pulp & Paper Research Journal. 2008; 23(3): 277-284. https://doi.org/10.3183/npprj-2008-23-03-p277-284

Kipphan H. Fundamentals. In: Handbook of Print Media. Berlin, Heidelberg: Springer. 2001. https://doi.org/10.1007/978-3-540-29900-4

BS 3110, Methods for measuring the rub resistance of print, 2017

Sharma G, Wu W, Dalal EN. The CIEDE2000 color-difference formula: Implementation notes, supplementary test data, and mathematical observations. Color Research & Application. 2004; 30(1):21-30. https://doi.org/10.1002/col.20070

Bates I, Plazonić I, Petric Maretić K, Rudolf M, Radić Seleš V. Assessment of the UV inkjet ink penetration into laboratory papers within triticale pulp and its influence on print quality. Coloration Technol. 2022; 138: 16– 27. https://doi.org/10.1111/cote.12563

Rudolf M, Petric Maretić K, Bates I, Plazonić I, Radić Seleš V. Assessment of durability of inkjet prints on laboratory paper substrates with wheat pulp based on rub resistance. In: Proceedings of the IV international conference on engineering technology and innovation, Skopje, Republic of North Macedonia, 2020, pp. 54-59.

Rudolf M, Plazonić I, Bates I, Radić Seleš V, Petric Maretić K. Evaluation of the rub resistance of offset UV ink layers on papers with wheat pulp, In: Proceedings of the 6th International Conference on Design and Graphic Arts (CIDAG) Alameda. Revista de Educação, Artes e Ciências, Lisabon, Portugal, 2021; 33-39.