Improvement of energy properties of lignocellulosic waste by thermochemical conversion into biochar Technical paper

Main Article Content

Abstract

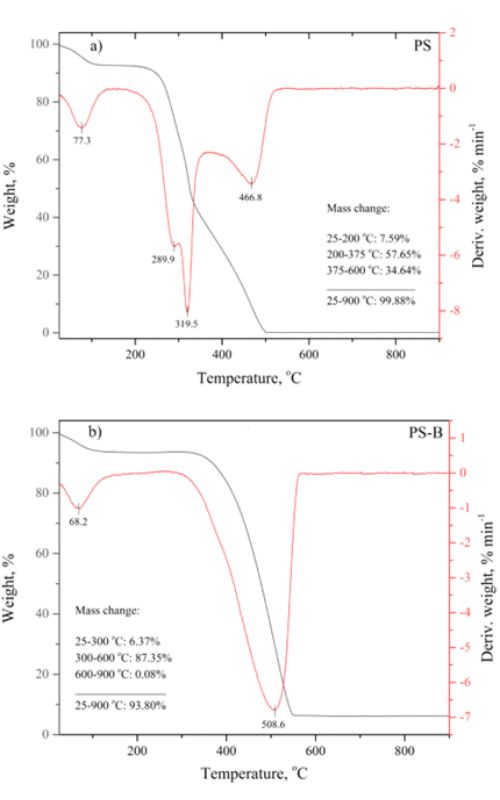

Peach stones, a valuable agro-industrial by-product available in many countries worldwide, comprise a renewable resource, which can be widely applied for multifunctional purposes. Its important advantages such as high-energy value, low ash content, low price and wide abundance, make peach stones an ideal fuel for energy production, but also for new materials synthesis. Although peach stones exhibit adequate combustion properties, allowing their direct use with minimal physical/chemical treatment, they often need further modification in order to improve their thermal properties, where slow pyrolysis is frequently used. This study aims to provide a practical and effective solution to the revalorization of waste biomass originating from the fruit processing industry, through slow pyrolysis in order to convert this waste into carbonaceous material – biochar. The thermo-chemical conversion of raw biomass resulted in a stable material with excellent fuel properties, with higher mass energy density and grinding ability, providing biochar with properties, in energy sense, similar or even better than a coal. Biochar has a higher fixed carbon content and a higher energy potential than biomass itself, and its application as a biofuel might reduce emissions of greenhouse gases, as it reduces the amount of waste landed and increases the share of energy generated from renewable sources.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

Funding data

-

Ministarstvo Prosvete, Nauke i Tehnološkog Razvoja

Grant numbers 451-03-47/2023-01/200023

References

Martín-Lara MA, Pérez A, Vico-Pérez MA, Calero M, Blázquez G. The role of temperature on slow pyrolysis of olive cake for the production of solid fuels and adsorbents. Process Saf Environ Prot. 2019; 121: 209-220. https://doi.org/10.1016/j.psep.2018.10.028

Council of the European Union. Proposal for a Directive of the European Parliament and of the Council on the promotion of the use of energy from renewable sources. 2018; http://data.consilium.europa.eu/doc/document/ST-10308-2018-INIT/en/pdf

Özçimen D, Ersoy-Meriçboyu A. Characterization of biochar and bio-oil samples obtained from carbonization of various biomass materials. Renew Energ. 2010; 35(6): 1319-1324. https://doi.org/10.1016/j.renene.2009.11.042

Kwapinski W, Byrne CMP, Kryachko E, Wolfram P, Adley C, Leahy JJ, Novotny EH, Hayes MHB. Biochar from biomass and waste. Waste Biomass Valorization. 2010; 1: 177–189. https://doi.org/10.1007/s12649-010-9024-8

Obernberger I, Thek G. Physical characterisation and chemical composition of densified biomass fuels with regard to their combustion behaviour. Biomass Bioenergy. 2004; 6: 653-669. https://doi.org/10.1016/j.biombioe.2003.07.006

Huang YF, Cheng PH, Chiueh PT, Lo SL. Leucaena biochar produced by microwave torrefaction: Fuel properties and energy efficiency. Appl Energy. 2017; 204: 1018-1025. https://doi.org/10.1016/j.apenergy.2017.03.007

Channiwala SA, Parikh PP. A unified correlation for estimating HHV of solid, liquid and gaseous fuels. Fuel. 2002; 8: 1051-1063. https://doi.org/10.1016/S0016-2361(01)00131-4

Nachenius RW, van de Wardt TA, Ronsse F, Prins W. Torrefaction of pine in a bench-scale screw conveyor reactor. Biomass Bioenergy. 2015; 79: 96–104. https://doi.org/10.1016/j.biombioe.2015.03.027

Kim D, Lee K, Park KY. Hydrothermal carbonization of anaerobically digested sludge for solid fuel production and energy recovery. Fuel. 2014; 130: 120-125. https://doi.org/10.1016/j.fuel.2014.04.030

Janković B, Manić N, Stojiljković D, Jovanović V. The assessment of spontaneous ignition potential of coals using TGA–DTG technique. Combust Flame. 2020; 211: 32-43. https://doi.org/10.1016/j.combustflame.2019.09.020

Weber K, Heuer S, Quicker P, Li T, Løvås T, Scherer V. An Alternative Approach for the Estimation of Biochar Yields. Energy Fuels. 2018; 32 (9), 9506-9512. https://doi.org/10.1021/acs.energyfuels.8b01825

Lopičić Z, Avdalović J, Milojković J, Antanasković A, Lješević M, Lugonja N, Šoštarić T. Removal of diesel pollution by biochar – Support in water remediation. Hem Ind. 2021; 75(6): 329-338. https://doi.org/10.2298/HEMIND210514029L

Jindo K, Mizumoto H, Sawada Y, Sanchez-Monedero MA, Sonoki T. Physical and chemical characterization of biochars derived from different agricultural residues. Biogeosciences. 2014; 11:6613–6621. https://doi.org/10.5194/bg-11-6613-2014

Abdullah H, Wu H. Biochar as a Fuel: 1. Properties and grindability of biochars produced from the pyrolysis of Mallee wood under slow-heating conditions. Energy Fuels. 2009; 23(8); 4174-4181. https://doi.org/10.1021/ef900494t

Lalak J, Martyniak D, Kasprzycka A, Żurek G, Moroń W, Chmielewska M, Wiącek D, Tys, J. Comparison of selected parameters of biomass and coal. Int Agrophys. 2016; 30(4): 475-482. https://doi.org/10.1515/intag-2016-0021

Dołżyńska M, Obidziński S, Piekut J, Yildiz G. The utilization of plum stones for pellet production and investigation of post-combustion flue gas emissions. Energies. 2020; 13(19): 5107. https://doi.org/10.3390/en13195107

Idris SS, Rahman NA, Ismail K, Alias AB, Rashid ZA, Aris MJ. Investigation on thermochemical behaviour of low rank Malaysian coal, oil palm biomass and their blends during pyrolysis via thermogravimetric analysis (TGA). Bioresour Technol. 2010; 101(12): 4584-4592, https://doi.org/10.1016/j.biortech.2010.01.059

Lopičić Z, Stojanović M, Kaluđerović Radoičić T, Milojković J, Petrović M, Mihajlović M, Kijevčanin M. Optimization of the process of Cu(II) sorption by mechanically treated Prunus persica L. - Contribution to sustainability in food processing industry. J Clean Prod. 2017; 156: 95-105, https://doi.org/10.1016/j.jclepro.2017.04.041

Serapiglia M, Cameron KD, Stipanovic A, Smart LB. Analysis of biomass composition using high-resolution thermogravimetric analysis and percent bark content for the selection of shrub willow bioenergy crop varieties. Bioenergy Res. 2009 2: 1-9. https://doi.org/10.1007/s12155-008-9028-4

Laird DA. The charcoal vision: a win-win-win scenario for simultaneously producing bioenergy, permanently sequestering carbon, while improving soil and water quality. Agron J. 2008; 100: 178-181. https://doi.org/10.2134/agronj2007.0161