Numerical simulation of titanium alloy hip replacement implants behaviour under static and dynamic loads Original scientific paper

Main Article Content

Abstract

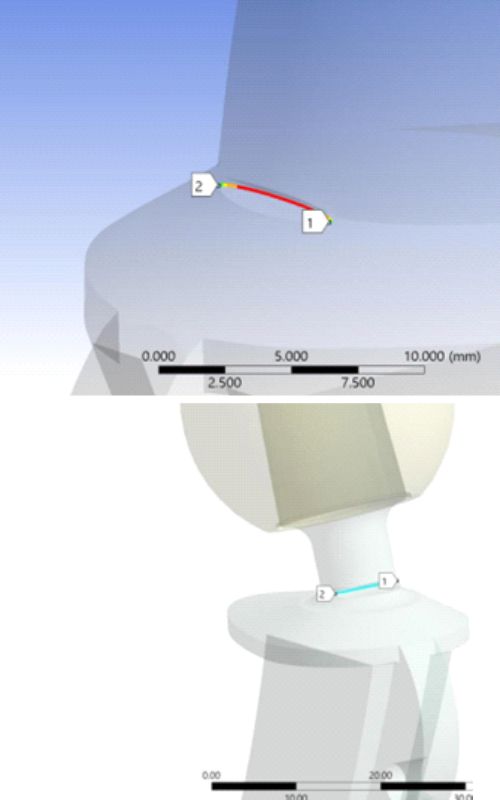

This paper presents development of numerical models for simulation of the behaviour of titanium alloy hip implants under static and dynamic loads, which is a part of extensive research involving the structural integrity of such implants under various loading conditions, as well as under exposure to aggressive environments. Numerical models were created in ABAQUS and ANSYS software packages, in order to determine the stress/strain distribution, the number of cycles to failure and stress intensity factors, for two different hip implant geometries. The ABAQUS models were used for static and ANSYS models for dynamic loads. The next stage in this analysis involved comparing these two cases, to determine the one with the better behaviour, depending on the exploitation conditions, which can greatly vary between different groups of patients. The targeted patient weight for all numerical simulations was 90 kg, while failure assessment diagrams were made for both implant geometries, assuming a crack length of 1 mm.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

Funding data

-

Ministarstvo Prosvete, Nauke i Tehnološkog Razvoja

Grant numbers 451-03-68/2022-14/200105;451-03-68/2022-14/200135

References

Sarraf M, Ghomi ER, Alipour S, Ramakrishna S, Sukiman NL. A state-of-the-art review of the fabrication and characteristics of titanium and its alloys for biomedical applications. Bio-des. Manuf. 2022; 5: 371-395. https://doi.org/10.1007/s42242-021-00170-3.

Kirmanidou Y, Sidira M, Drosou ME, Bennani V, Bakopoulou A, Tsouknidas A, Michailidis N, Michalakis K. New Ti-Alloys and Surface Modifications to Improve the Mechanical Properties and the Biological Response to Orthopedic and Dental Implants: A Review. BioMed Res Inter. 2016; 2908570. https://doi.org/10.1155/2016/2908570.

Eisenbarth E, Velten D, Muller M, Thull R, Breme J. Biocompatibility of beta-stabilizing elements of titanium alloys. Biomaterials 2004; 25(26): 5705-5713. https://doi.org/ 10.1016/j.biomaterials.2004.01.021.

Niinomi M, Nakai M, Hieda J. Development of new metallic alloys for biomedical applications. Acta Biomater. 2012; 8(11): 3888-3903. https://doi.org/ 10.1016/j.actbio.2012.06.037.

Sedmak A, Čolić K, Burzić Z, Tadić S. Structural integrity assessment of hip implant made of cobalt-chromium multiphase alloy. Struct Integr Life. 2010; 10(2): 161-164. http://divk.inovacionicentar.rs/ivk/ivk10/161-IVK2-2010-AS-KC-ZB-ST.pdf.

Milovanović A, Sedmak A, Čolić K, Tatić U, Đorđević B. Numerical analysis of stress distribution in total hip replacement implant. Struct Integr Life. 2017; 17(2): 139-144. http://divk.inovacionicentar.rs/ivk/ivk17/139-IVK2-2017-AM-AS-KC-UT-BDj.pdf.

Milovanović A, Sedmak A, Grbović A, Mijatović T, Čolić K. Design Aspects of Hip Implant Made of Ti-6Al-4V Extra Low Interstitials Alloy. Procedia Struct Integr. 2020; 26: 299-305. https://doi.org/10.1016/j.prostr.2020.06.038.

Mijatović T, Milovanović A, Sedmak A, Milović Lj, Čolić K. Integrity assessment of reverse engineered TI-6AL-4V ELI total hip replacement implant. Struct Integr Life. 2019; 19(3): 237-242. http://divk.inovacionicentar.rs/ivk/ivk19/237-IVK3-2019-TM-AM-AS-LjM-KC.pdf.

Sedmak A, Čolić K. Fracture and fatigue behaviour of implants made of Ti alloys. Procedia Struct Integr. 2019; 23: 45-50. https://doi.org/10.1016/j.prostr.2020.01.061.

Čolić K, Sedmak A, Legweel K, Milošević M, Mitrović N, Mišković Ž, Hloch S. Experimental and numerical research of mechanical behaviour of titanium alloy hip implant. Teh Vjesn. 2017; 24(3): 709-713. https://doi.org/10.17559/TV-20160219132016.

Čolić K, Sedmak A, Grbović A, Tatić U, Sedmak SA, Đorđević B. Finite element modeling of hip implant static loading. Procedia Eng. 2016; 149: 257-262. https://doi.org/10.1016/j.proeng.2016.06.664.

Sedmak A, Čolić K, Grbović A, Balać I, Burzić M. Numerical analysis of fatigue crack growth of hip implant. Eng Fract Mech. 2019; 216: 106492. https://doi.org/ 10.1016/j.engfracmech.2019.106492.

Sedmak A, Kirin S, Martić I, Jeremić L, Vučetić I, Golubović Sedmak T, Sedmak SA. Structural Integrity and Life Assessment of Pressure Vessels - Risk Based Approach. In: Experimental and Computational Investigations in Engineering, Proceedings of the International Conference of Experimental and Numerical Investigations and New Technologies, CNNTech2020, Springer, 2020: 274–293. https://doi.org/10.1007/978-3-030-58362-0_16.

Golubović T, Sedmak A, Spasojević Brkić V, Kirin S, Rakonjac I. (2018). Novel Risk Based Assessment of Pressure Vessels Integrity. Teh Vjesn. 2018; 25(3): 803-807. https://doi.org/ 10.17559/tv-20170829144636.

Kirin S, Jeremić L, Sedmak A, Martić I, Sedmak SA, Vučetić I, Golubović T. Risk based analysis of RHPP penstock structural integrity. Frat ed Integrita Strutt.2020; 14(53): 345-352. https://doi.org/ 10.3221/IGF-ESIS.53.27.

Golubović T, Sedmak A, Spasojević Brkić V, Kirin S, Veg, E. Welded joints as critical regions in pressure vessels – Case study of vinyl-chloride monomer storage tank. Hem Ind. 2018; 72(4): 177-182. https://doi.org/10.2298/HEMIND171009006G.

Sedmak A, Zaidi R, Vujičić B, Šarkočević Ž, Kirin S, Stamenić Z, Đukić M, Bakić G. Corrosion effects on structural integrity and life of oil rig drill pipes. Hem Ind. 2022; 76(3):167-177. https://doi.org/10.2298/HEMIND220222014S.ž

Zaidi R, Sedmak A, Kirin S, Grbović A, Wei L, Lazić Vulićević Lj, Šarkočević Ž. Risk assessment of oil drilling rig welded pipe based on structural integrity and life estimation. Eng Fail Anal. 2020; 112: 104508. https://doi.org/10.1016/j.engfailanal.2020.104508.

Kirin S, Sedmak A, Zaidi R, Grbović A, Šarkočević Ž. Comparison of experimental, numerical and analytical risk assessment of oil drilling rig welded pipe based on fracture mechanics parameters. Eng Fail Anal. 2020; 114: 104600. https://doi.org/10.1016/j.engfailanal.2020.104600

Chen, X.G, Wu, X.G, Yan, M.G. Dugdale model for strain hardening materials. Eng. Fract. Mech. 1992; 41(6):843-871. https://doi.org/10.1016/0013-7944(92)90236-8.

Lee, J-S, Ju, J-B, Jang, J-I, Kim, W-S, Kwon, D. Weld crack assessments in API X65 pipeline: failure assessment diagrams with variations in representative mechanical properties. Mater Sci Eng. A 2004; 373:122-130. https://doi.org/10.1016/j.msea.2003.12.039.