Physical simulation of finish rolling of microalloyed steels in isothermal conditions Original scientific paper

Main Article Content

Abstract

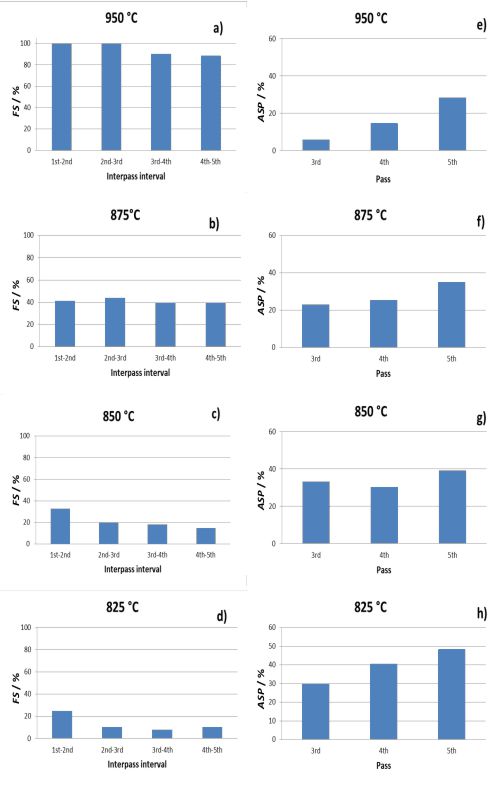

The aim of this work was to establish a temperature of finish rolling stage of Nb/Ti microalloyed steel containing 0.06 wt.% C, 0.77 wt.% Mn, 0.039 wt.% Nb and 0.015 wt.% Ti, using physical simulation. Samples were subjected to laboratory simulation at a twist plastometer at high temperatures, i.e. between 825 and 950 °C. Five pass deformation and interpass times were selected in accordance with a processing parameters at five stand finishing hot strip mill. Restoration (recovery and/or recrystallization) behavior was evaluated by calculation of Fraction Softening (FS) and Area Softening Parameter (ASP) values. At 950 °C all individual pass stress-strain curves, FS and ASP show full recrystallization in all interpass intervals. On the other hand, with a decrease in temperature to the interval of 875-825 °C, the extent of restoration is decreasing, leading to recovery as a sole softening mechanism at 825 °C, which was confirmed by the stress-strain curve shape, and values of FS and ASP. It is assumed that, due to high supersaturation, strain-induced precipitation promoted pinning of grain and subgrain boundaries and suppressed recrystallization. Therefore, the critical temperature for finish rolling was estimated to be 825 °C.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

Funding data

-

Ministarstvo Prosvete, Nauke i Tehnološkog Razvoja

Grant numbers Contract No. 451-03-68/2022-14/200135

References

Villalobos JC, Del-Pozo A, Campillo B, Mayen J, Serna S. Microalloyed steels through history until 2018: Review of chemical composition, processing and hydrogen service. Metals (Basel) 2018;8(5). https://doi.org/10.3390/met8050351

Morrison BW. Microalloyed steels for offshore application. In: Microalloying ’95. Pittsburgh, USA; 1995;105–16; ISBN 0932897983

Siwecki T, Hutchinson B, Zajac S. Recrystallization controlled rolling of HSLA steels. In: Microalloying ’95. Pittsburgh, USA; 1995;197–211; ISBN 0932897983

Collins LE, Baragar DL, Bowker JT, Kostic MM, Subramanian SV. Steckel Mill Process Optimization for Production of X70 and X80 Gas Transmission Linepipe. In: Microalloying ’95. Pittsburgh, USA: 1995;141–7; ISBN 0932897983

Tanaka T. Science and technology of hot rolling process of steel. In: Microalloying ’95. Pittsburgh, USA; 1995;165–81; ISBN 0932897983

Drobnjak D, Radović N. A Contribution to the Study of Dynamic Recrystallization in a Nb/Ti Microalloyed Steel. Mater Sci Forum 1993;113–115:411–6. https://doi.org/10.4028/www.scientific.net/msf.113-115.411

Siciliano F, Jonas J. Mathematical modeling of the hot strip rolling of Nb microalloyed steels. Metall Mater Trans A 2000; 31A: 501—530. https://doi.org/10.1007/s11661-000-0287-8

Dutta B, Sellars CM. Predictions from nucleation theory. Mater Sci Technol 1987; 3: 197–206. https://doi.org/10.1179/mst.1987.3.3.197

Yue S, Jonas JJ. The three critical temperatures of steel rolling and their experimental determination. Mater Forum 1990;14(4):245

Ballard TJ, Speer JG, Findley KO, De Moor E. Double twist torsion testing to determine the non-recrystallization temperature. Sci Rep 2021;11(1). https://doi.org/10.1038/s41598-021-81139-1

Felker CA, Speer JG, De Moor E, Findley KO. Hot strip mill processing simulations on a Ti-Mo microalloyed steel using hot torsion testing. Metals (Basel) 2020;10(3). https://doi.org/10.3390/met10030334

Drobnjak D, Radovic N, Djuric B. Effect of Test Variables on QHW and Tnr. In: Mechanical Working and Steel Processing Conference. Ontario, Canada; 1995; 759–68; ISBN: 9781886362055

Kwon O, DeArdo AJ. Niobium carbonitride precipitation and static softening in hot-deformed niobium microalloyed steels. In: HSLA STEELS: METALLURGY AND APPLICATION. Beijing, China; 1985;287–98; ISBN: 0-87170-299-0

Palmiere EJ, Garcia CI, DeArdo AJ. Static Recrystallization and Precipitation During the Hot Deformation of Austenite. In: International Conference on Processing, Microstructure and Properties of Microalloyed and Other Modern High Strength Low Alloy Steels. Pittsburgh: Iron and Steel Society; 1991;113–33; ISBN: 0932897711

Andrade HL, Akben MG, Jonas JJ. Effect of Molybdenum, Niobium, and Vanadium on Static Recovery and Recrystallization and on Solute Strengthening in Microalloyed Steels. Metall Trans A 1983;14A:1967–77. https://doi.org/10.1007/BF02662364

F. Boratto, R. Barbosa, S. Yue, J.J. Jonas, In: THERMEC-88, Tokyo, Japan, Vol. 1 (1988) 383-389.

Fernández AI, López B, Rodríguez-Ibabe JM. Relationship between the austenite recrystallized fraction and the softening measured from the interrupted torsion test technique. Scr Mater 1999;40(5):543–9. https://doi.org/10.1016/S1359-6462(98)00452-7

Radovic N, Drobnjak D. Effect of Interpass Time and Energy for Hot Working and of Nb-microalloyed Steel Cooling Rate on Apparent Activation Critical Recrystallization Temperature. ISIJ Int 1999; 39(6): 575–82 https://doi.org/10.2355/isijinternational.39.575

Semiatin SL, Jonas JJ. Formability and workability of metals: plastic instability and flow localization. Ohio: American Society for Metals; 1984, ISBN: 0871701839

Fadel AH, Radović N. Determination of Activation Energy For Static Re-Crystallization in Nb-Ti Low Carbon Micro Alloyed Steel. Int J Eng Inf Technol 2017;3(2):164–9. http://mdr.misuratau.edu.ly/bitstream/handle/123456789/313/IJEIT06201615.pdf?sequence=1&isAllowed=y

Rout M, Ranjan R, Pal SK, Singh SB. Study on Static Recrystallization Behavior of 304LN Stainless Steel by Two-stage Compression Test. In: All India Manufacturing Technology, Design and Research Conference (AIMTDR-2016); Maharashtra, India; 2016:1007–11; ISBN: 978-93-86256-27-0

Ferreira JC, de Sousa Machado FR, Aranas C, et al. Physical Simulation Based on Dynamic Transformation Under Hot Plate Rolling of a Nb-Microalloyed Steel. Front Mater 2021;8. https://doi.org/10.3389/fmats.2021.716967

Rodrigues SF, Siciliano F, Aranas C, Silva ES, Reis GS, Jonas JJ. High-Temperature Deformation Behaviour of High-Nb Microalloyed Steel During Plate Rolling Simulation. Tecnol Em Metal Mater e Mineração 2020;17(2):105–11. https://doi.org/10.4322/2176-1523.20202231

Dutta B, Valdes E, Sellars CM. Mechaism and Kinetics of Strain Induced Precipitation of Nb(C,N) in Austenite. Acta Met Mater 1992;40(4):653–62. https://doi.org/10.1016/0956-7151(92)90006-Z

Irvine K, Pickering F, Gladman T. Grain-refined C-Mn steels . J Iron Steel Inst 1967; 205(2): 161–82

Chilton JM, Roberts MJ. Microalloying Effects in Hot-Rolled Low-Carbon Steels Finished at High Temperatures. Metall Trans A 1980;11A:1711–21. https://doi.org/10.1007/BF02660526

Medina SF, Hernandez CA. General Expression of the Zener-Hollomon Parameter as a Function of the Chemical Composition of Low Alloy and Microalloyed Steels. Acta Mater 1996;44(1):137–48. https://doi.org/10.1016/1359-6454(95)00151-0

Pussegoda LN, Jonas JJ. Comparison of Dynamic Recrystallization and Rolling Schedules by Laboratory Simulation Conventional Controlled. ISIJ Int 1991;31(3):278–88. https://doi.org/10.2355/isijinternational.31.278

Jonas JJ, Ghosh C, Basabe V V. Effect of dynamic transformation on the mean flow stress. Steel Res Int 2013;84(3):253–8. https://doi.org/10.1002/srin.201200166