Recent advances in waste-based and natural zeolitic catalytic materials for biodiesel production Review paper

Main Article Content

Abstract

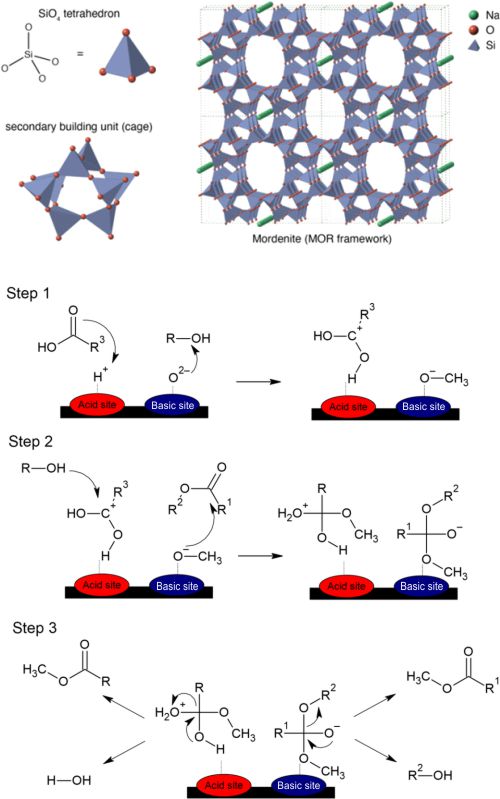

Considering the current world crisis and definite future energy challenges, biomass-to-fuel transformation is increasingly becoming important both to the policy makers and to the industry. In this perspective, the valorisation of oils and fats via transesterification/esterification reaction is an attractive method for producing biodiesel with qualities suitable for diesel engines. The recent interest indicated a significant shift to industrial waste valorisation as another approach for achieving process eco-efficiency. In this respect, the use of zeolite-based catalysts for the production of biofuels is reviewed here, with a special emphasis on the utilization of waste raw materials following the principles of green chemistry and sustainable development. Zeolites are interesting due to their outstanding catalytic properties, including the presence of intrinsic acid sites, simple loading of base sites, shape-selectivity, and high thermal stability. Neat zeolites or modified by the loading of active species are classified into several groups following their origin. For each group, the most relevant recent results reported in the literature are reviewed together with some critical considerations on the catalyst effectiveness, stability, reusability, and economy of synthesis. As an important part required for understanding and optimization of the biodiesel production process, the mechanisms of the reaction were discussed in detail. Finally, key perspective directions for further research studies were carefully identified and elaborated.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

Funding data

-

Ministarstvo Prosvete, Nauke i Tehnološkog Razvoja

Grant numbers 451-03-68/2022-14/200026

References

Banković-Ilić IB, Stamenković OS, Veljković VB. Biodiesel production from non-edible plant oils. Renew Sust Energ Rev 2012; 16(6): 3621-3647. https://doi.org/10.1016/j.rser.2012.03.002

Chen K, Wang J, Dai Y, Wang P, Liou C, Nien C, Wu J, Chen C. Rice husk ash as a catalyst precursor for biodiesel production. J Taiwan Inst Chem Eng. 2013; 44(4): 622-629. http://dx.doi.org/10.1016/j.jtice.2013.01.006

Miladinović, MR, Krstić JB, Zdujić MV, Veselinović LjM, Veljović DjN, Banković-Ilić IB, Stamenković OS, Veljković VB. Transesterification of used cooking sunflower oil catalyzed by hazelnut shell ash. Renew Energy. 2022; (183): 103-113. https://doi.org/10.1016/j.renene.2021.10.071

Petković M, Miladinović M, Banković-Ilić I, Stamenković O, Veljković V. Optimization of the used sunflower oil methanolysis catalyzed by hazelnut shell ash. Adv Technol. 2021; 10(2): 32-39. https://doi.org/10.5937/savteh2102032P

Miladinović MR, Krstić JB, Ivana B. Banković-Ilić, Vlada B. Veljković, Stamenković OS. Valorization of walnut shell ash as a catalyst for biodiesel production. Renew Energy. 2020; 147: 1033-1043. https://doi.org/10.1016/j.renene.2019.09.056

Fatimah I, Purwiandono G, Sahroni I, Sagadevan S, Chun-Oh W, Ghazali SAISM, Doong R. Recyclable catalyst of ZnO/SiO2 prepared from Salacca leaves ash for sustainable biodiesel conversion. South African J Chem Eng. 2022; 40: 134–143. https://doi.org/10.1016/j.sajce.2022.02.008

Fatimah I, Taushiyah A, Najah FB, Azmi U. ZrO2/bamboo leaves ash (BLA) catalyst in biodiesel conversion of rice bran oil. Mater Sci Eng. 2018; 349: 012027. https://doi.org/10.1088/1757-899X/349/1/012027

Fatimah I, Yanti I, Totok E. Suharto TE, Sagadevan S. ZrO2-based catalysts for biodiesel production: A review. Inorg Chem Commun. 2022; 143: 109808. https://doi.org/10.1016/j.inoche.2022.109808

Wang L, Yu H. Biodiesel from Siberian apricot (Prunus sibirica L.) seed kernel oil. Biores Technol 2012; 112: 355-358, https://doi.org/10.1016/j.biortech.2012.02.120

Rashid U, Rehman H A., Hussain I, Yusup S. Production and characterization of biodiesel produced from musk melon (Cucumis melo) seed oil. In: BIT’s 1st Annual World Congress of Bioenergy (WCBE 2011), 25-30 April 2011, Dalian, China.

Chu J, Xu X, Zhang Y. Production and properties of biodiesel produced from Amygdalus pedunculata Pall. Biores Technol. 2013; 134: 374-376. https://doi.org/10.1016/j.biortech.2012.12.089

Schinas P, Karavalakis G, Davaris C, Anastopoulos G, Karonis D, Zannikos F, Stournas S, Lois E. Pumpkin (Cucurbita pepo L.) seed oil as an alternative feedstock for the production of biodiesel in Greece. Biomass Bioenerg. 2009; 33(1): 44-49, https://doi.org/10.1016/j.biombioe.2008.04.008

Rashid U, Ibrahim M, Yasin S, Yunus R, Taufiq-Yap Y-H, Knothe G. Biodiesel from Citrus reticulata (mandarin orange) seed oil, a potential non-food feedstock. Ind Crops Prod. 2013; 45: 355-359, https://doi.org/10.1016/j.indcrop.2012.12.039

Crops and livestock products, Food and Agriculture Organization of the United Nations, https://www.fao.org/faostat/en/#data/QCL accessed November 3, 2022

Saeed A, Hanif MA, Haq Nawaz RWKQ. The production of biodiesel from plum waste oil using nano-structured catalyst loaded into supports. Sci Rep. 2021; 11: 24120. https://doi.org/10.1038/s41598-021-03633-w

Kostić MD, Veličković AV, Joković NM, Stamenkovic OS, Veljkovic VB. Optimization and kinetic modeling of esterification of the oil obtained from waste plum stones as a pretreatment step in biodiesel production. Waste Manag. 2016; 48: 619-629. https://doi.org/10.1016/j.wasman.2015.11.052

Górna P, Rudzi M, Soliven A. Industrial by-products of plum Prunus domestica L . and Prunus cerasifera Ehrh. as potential biodiesel feedstock: Impact of variety. Ind Crops Prod. 2017; 100: 77-84. https://doi.org/10.1016/j.indcrop.2017.02.014

Vicente G, Martinez M, Aracil J, Esteban A. Kinetics of sunflower oil methanolysis. Ind Eng Chem Res. 2005; 44: 5447-5454. https://doi.org/10.1021/ie040208j

Vicente G, Martinez M, Aracil J. Kinetics of Brassica carinata oil methanolysis. Energ Fuels 2006; 20: 1722-1726. https://doi.org/10.1021/ef060047r

Georgogianni KG, Kontominas MG, Pomonis PJ, Avlonitis D, Gergis V. Alkaline conventional and in situ transesterification of cottonseed oil for the production of biodiesel. Energ Fuels. 2008; 22: 2110-2115. https://doi.org/10.1021/ef700784j

Jamil AZ, Muslim A. Performance of KOH as a catalyst for transesterification of Jatropha curcas oil. Int J Eng Res Appl. 2012; 2: 635-639. ISSN: 2248-9622

Rabu RA, Janajreh I, Honnery D. Transesterification of waste cooking oil: Process optimization and conversion rate evaluation. Energ Conv Manag. 2013; 65: 764-769. https://doi.org/10.1016/j.enconman.2012.02.031

Kostić MD, Joković NM, Stamenković OS, Veljković VB. Biodiesel production from seed oil of cotton thistle (Onopordum acanthium L.). Adv Technol. 2014; 3: 35-45. UDK 62.756.3:66.061.34:582.998.1 (In Serbian)

Stamenković OS, Kostić MD, Joković NM, Veljković VB. The kinetics of base-catalyzed methanolysis of waste cooking oil. Adv Technol. 2015; 4(1): 33-41. https://doi.org/10.5937/savteh1501033S

Kostić MD, Stamenković OS, Veljković VB. The influence of fatty acid composition on the kinetics of the vegetable oil methanolysis reaction. Adv Technol. 2021; 10(2): 24-31. https://doi.org/10.5937/savteh2102024K

Mares EKL, Matheus A, Teresa P, Rafael L. Acai seed ash as a novel basic heterogeneous catalyst for biodiesel synthesis: Optimization of the biodiesel production process. Fuel. 2021; 299: 120887. https://doi.org/10.1016/j.fuel.2021.120887

Sitepu EK, Sembiring Y, Supeno M, Tarigan K, Ginting J, Karo-karo JA, Tarigan JB. Homogenizer-intensified room temperature biodiesel production using heterogeneous palm bunch ash catalyst. South African J Chem Eng. 2022; 40: 240–245. https://doi.org/10.1016/j.sajce.2022.03.007

Pathak G, Das D, Rajkumari K, Rokhum L. Exploiting waste: Towards a sustainable production of biodiesel using: Musa acuminata peel ash as a heterogeneous catalyst. Green Chem. 2018; 20(10): 2365-2373. https://doi.org/10.1039/C8GC00071A

Husin H, Abubakar A, Ramadhani S, Sijabat CFB, Hasfita F. Coconut husk ash as heterogenous catalyst for biodiesel production from Cerbera manghas seed oil. MATEC Web of Conferences, The 3rd Annual Applied Science and Engineering Conference. Bundung, Indonesia, 2018, vol. 197, p. 09008. https://doi.org/10.1051/matecconf/201819709008

de Barros S, Pessoa Junior WAG, Sá ISC, Takeno ML, Nobre FX, Pinheiro W, Manzato L, Iglauer S, de Freitas FA. Pineapple (Ananás comosus) leaves ash as a solid base catalyst for biodiesel synthesis. Bioresour Technol. 2020; 312: 123569. https://doi.org/10.1016/j.biortech.2020.123569

Vargas EM, Ospina L, Neves MC, Tarelho LAC, Nunes MI. Optimization of FAME production from blends of waste cooking oil and refined palm oil using biomass fly ash as a catalyst. Renew Energ. 2021; 163: 1637-1647. https://doi.org/10.1016/j.biortech.2020.123569

Adepojua TF, Ibeha MA, Babatunde EO, Asuquo AJ, Abegunde GS. Appraisal of CaO derived from waste fermented-unfermented kola nut pod for fatty acid methylester (FAME) synthesis from Butyrospermum parkii (Shea butter) oil. South African J Chem Eng 2020; 33: 160–171. https://doi.org/10.1016/j.sajce.2020.07.008

Hsiao M-C, Liao P-H, Lan NV, Hou S-S. Enhancement of biodiesel production from high-acid-value waste cooking oil via a microwave reactor using. Energies. 2021; 14: 437. https://doi.org/10.3390/en14020437

Miladinović MR, Stamenković OS, Veljković VB, Skala DU. Continuous sunflower oil methanolysis over quicklime in a packed-bed tubular reactor. Fuel. 2015; 154: 301-307. https://doi.org/10.1016/j.fuel.2015.03.057

Veljković VB, Stamenković OS, Todorović ZB, Lazić ML, Skala DU. Kinetics of sunflower oil methanolysis catalyzed by calcium oxide. Fuel. 2009; 88: 1554–1562. https://doi:10.1016/j.fuel.2009.02.013

Nath B, Kalita P, Das B, Basumatary S. Highly efficient renewable heterogeneous base catalyst derived from waste Sesamum indicum plant for synthesis of biodiesel. Renew Energy. 2020; 151: 295-310. https://doi.org/10.1016/j.renene.2019.11.029

Vassilev S V., Vassileva CG, Song YC, Li WY, Feng J. Ash contents and ash-forming elements of biomass and their significance for solid biofuel combustion. Fuel. 2017; 208: 377-409. https://doi.org/10.1016/j.fuel.2017.07.036

Vassilev S V, Baxter D, Vassileva CG. An overview of the behaviour of biomass during combustion : Part II. Ash fusion and ash formation mechanisms of biomass types. Fuel. 2014; 117: 152-183. https://doi.org/10.1016/j.fuel.2013.09.024

Zdujić M, Lukić I, Kesić Ž, Janković-Častvan I, Marković S, Jovalekić Č, Skala D. Synthesis of CaOSiO2 compounds and their testing as heterogeneous catalysts for transesterification of sunflower oil. Adv Powder Technol. 2019; 30: 1141-1150. https://doi.org/10.1016/j.apt.2019.03.009

Emeruwa E, Jarrige J, Mexmain J, Bernardin M. Application of mercury porosimetry to powder (UO2) analysis. J Nucl Mater. 1991; 184(1): 53-58. https://doi.org/10.1016/0022-3115(91)90532-C

Lukić I, Krstić J, Jovanović D, Skala D. Alumina/silica supported K2CO3 as a catalyst for biodiesel synthesis from sunflower oil. Bioresour Technol. 2009; 100: 4690-4696. https://doi.org/10.1016/j.biortech.2009.04.057

Yang P, Zhou S, Du Y, Li J, Lei J. Self-assembled meso / macroporous phosphotungstic acid/TiO2 as an efficient catalyst for oxidative desulfurization of fuels. J Porous Mater. 2017; 24: 531-539. https://doi.org/10.1007/s10934-016-0288-7

Fraile JM, García N, Mayoral JA, Pires E, Roldán L. The basicity of mixed oxides and the influence of alkaline metals: The case of transesterification reactions. Appl Catal A: General. 2010; 387: 67-74. https://doi.org/10.1016/j.apcata.2010.08.002

Buchori L, Istadi I, Purwanto P, Marpaung LC, Safitri RL. Roles of K2O on the CaO-ZnO catalyst and its influence on catalyst basicity for biodiesel production. E3S Web Conf ICENIS 2017. 2018; 31(3): 02009. https://doi.org/10.1051/e3sconf/20183102009

Tang Y, Liu H, Ren H, Cheng Q, Cui Y, Zhang J. Development KCl/CaO as a catalyst for biodiesel production by tri-component coupling transesterification. Sust Energ. 38(2); 2018: 647-653. https://doi.org/10.1002/ep.12977

Mendonça IM, Paes OARL, Maia PJS, Souza MP, Almeida RA, Silva CC, Duvoisin S, de Freitas FA. New heterogeneous catalyst for biodiesel production from waste tucumã peels (Astrocaryum aculeatum Meyer): Parameters optimization study. Renew Energy. 2019; 130: 103-110. https://doi.org/10.1016/j.renene.2018.06.059

Betiku E, Mistura A, Victor T. Banana peels as a biobase catalyst for fatty acid methyl esters production using Napoleon’s plume (Bauhinia monandra) seed oil: A process parameters optimization study. Energy. 2016; 103: 797-806. https://doi.org/10.1016/j.energy.2016.02.138

Luque R, Pineda A, Colmenares JC, Campelo JM, Romero AA, Serrano-Riz JC, Cabeza LF, Cot-Gores J. Carbonaceous residues from biomass gasification as catalysts for biodiesel production. J Nat Gas Chem. 2012; 21(3): 246-250. https://doi.org/10.1016/S1003-9953(11)60360-5

Chouhan APS, Sarma AK. Biodiesel production from Jatropha curcas L. oil using Lemna perpusilla Torrey ash as heterogeneous catalyst. Biomass Bioenerg. 2013; 55: 386-389. https://doi.org/10.1016/j.biombioe.2013.02.009

Ho WWS, Kiat H, Gan S, Huey S. Evaluation of palm oil mill fly ash supported calcium oxide as a heterogeneous base catalyst in biodiesel synthesis from crude palm oil. Energ Conv Manag. 2014; 88: 1167-1178. http://dx.doi.org/10.1016/j.enconman.2014.03.061

Roschat W, Siritanon T, Yoosuk B, Promarak V. Rice husk-derived sodium silicate as a highly efficient and low-cost basic heterogeneous catalyst for biodiesel production. Ener Conv Manag. 2016; 119: 453-462. https://doi.org/10.1016/j.enconman.2016.04.071

Nath B, Das B, Kalita P, Basumatary S. Waste to value addition: Utilization of waste Brassica nigra plant derived novel green heterogeneous base catalyst for effective synthesis of biodiesel. J Clean Prod. 2019; 239: 118112. https://doi.org/10.1016/j.jclepro.2019.118112

Changmai B, Rano R, Vanlalveni C, Rokhum L. A novel Citrus sinensis peel ash coated magnetic nanoparticles as an easily recoverable solid catalyst for biodiesel production. Fuel. 2021; 286: 119447. https://doi.org/10.1016/j.fuel.2020.119447