Effects of temperature on physicochemical properties of the lecithin-based deep eutectic solvents and their use in the CaO-catalyzed transesterification Original scientific paper

Main Article Content

Abstract

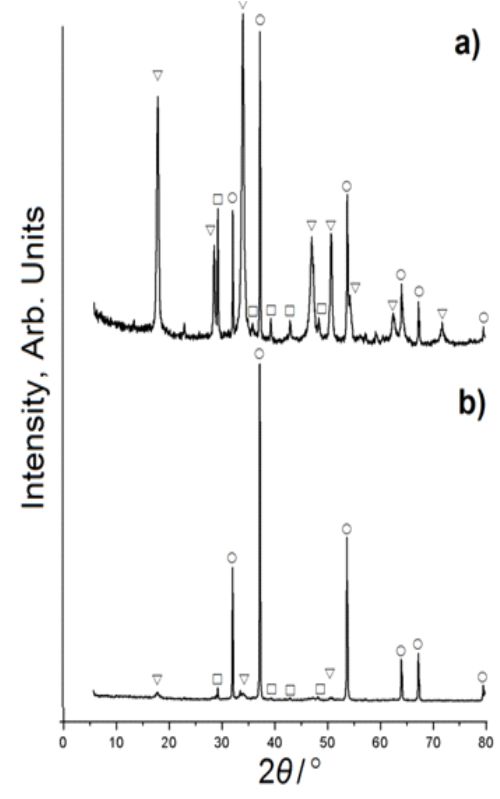

Deep eutectic solvents (DESs) are called 'designer solvents' due to various structural variations and the benefit of tailoring their physicochemical properties. For industrial applications of DESs it is crucial to know their physical and thermodynamic properties such as density, viscosity, and refractive index. These properties were measured for three lecithin (LEC)-based DESs with glycerol (G), triethanolamine (TEOA), and oleic acid (OLA) as functions of temperature. The viscosity was fitted by both Arrhenius-type and Vogel-Tamman-Fulcher equations. The density, viscosity, and refractive index of tested DESs decreased with the increase in temperature. The LEC:G DES exhibited the lowest density at all tested temperatures. This DES was selected as a cosolvent in the ethanolysis of cold-pressed black mustard (Brassica nigra L.) seed oil catalyzed by either calcined or non-calcined CaO. The reaction was carried out in a batch stirred reactor under the following conditions: the temperature of 70 °C, the ethanol-to-oil molar ratio of 12:1, and the amount of DES and CaO of 20 and 10 wt.% (to oil), respectively. The presence of DES accelerated the reaction, while the separation of the final reaction mixture phases was faster.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

Funding data

-

Ministarstvo Prosvete, Nauke i Tehnološkog Razvoja

Grant numbers 451-03-68/2022-14/200133 -

Serbian Academy of Sciences and Arts

Grant numbers 0-14-18

References

Bergua F, Delso I, Muñoz-Embid J, Lafuente C, Artal M. Structure and properties of two glucose-based deep eutectic systems. Food Chem. 2021; 336: 127717. https://doi.org/10.1016/j.foodchem.2020.127717

Balaraman HB, Rathnasamy SK. Kinetics and microwave-assisted extractive transesterification studies of high octane methyl esters (HOME) from karanja and chicken lard oil using protic deep eutectic solvent. Fuel. 2020; 268: 117299. https://doi.org/10.1016/j.fuel.2020.117299

Manurung R, Taslim T, Siregar AGA. Deep eutectic solvents based choline chloride for enzymatic biodiesel production from degumming palm oil. Asian J. Chem. 2020; 3: 733–738. https://doi.org/10.14233/ajchem.2020.22193

Troter DZ, Todorović ZB, Đokić-Stojanović DR, Veselinović LjM, Zdujić MV, Veljković VB. Choline chloride-based deep eutectic solvents in CaO-catalyzed ethanolysis of expired sunflower oil. J Mol Liq. 2018; 266: 557–567. https://doi.org/10.1016/j.molliq.2018.06.106

Merza F, Fawzy A, AlNashef I, Al-Zuhair S., Taher H. Effectiveness of using deep eutectic solvents as an alternative to conventional solvents in enzymatic biodiesel production from waste oils. Energy Rep. 2018; 4: 77–83. https://doi.org/10.1016/j.egyr.2018.01.005

Gu L, Huang W, Tang S, Tian S, Zhang X. A novel deep eutectic solvent for biodiesel preparation using a homogeneous base catalyst. Chem Eng Sci. 2015; 259: 647–652. https://doi.org/10.1016/j.cej.2014.08.026

Zhang Y, Xia X, Duan M, Han Y, Liu J, Luo M, Zhao C, Zu Y, Fu Y. Green deep eutectic solvent assisted enzymatic preparation of biodiesel from yellow horn seed oil with microwave irradiation. J Mol Catal B Enzym. 2016; 123: 35–40. https://doi.org/10.1016/j.molcatb.2015.10.013

Alam MM, Rahman KA. Biodiesel from mustard oil: a sustainable engine fuel substitute for Bangladesh. Int J Renew Energy Dev. 2013; 2: 141–149. https://doi.org/10.14710/ijred.2.3

Đorđević BS, Troter DZ, Todorović ZB, Đalović IG, Stanojević LjP, Mitrović PM, Veljković VB. The effect of the triethanolamine: glycerol deep eutectic solvent on the yield, fatty acid composition, antioxidant activity, and physicochemical properties of black mustard (Brassica nigra L.) seed oil. J Food Meas Charact. 2020; 14: 2570–2577. https://doi.org/10.1007/s11694-020-00503-3

Aslan V, Eryilmaz T. Polynomial regression method for optimization of biodiesel production from black mustard (Brassica nigra L.) seed oil using methanol, ethanol, NaOH, and KOH, Energy. 2020; 209: 118386. https://doi.org/10.1016/j.energy.2020.118386

Knothe G. Dependence of biodiesel fuel properties on the structure of fatty acid alkyl esters. Fuel Process Technol. 2005; 86: 1059‒70. https://doi.org/10.1016/j.fuproc.2004.11.002

Shahzadi I, Sadaf S, Iqbal J, Ullah I, Bhatti HN. Evaluation of mustard oil for the synthesis of biodiesel: Pretreatment and optimization study. Environ Prog Sustain Energy. 2018; 37: 1829–1835. https://doi.org/10.1002/ep.12833

Robert C, Couëdelo L, Vaysse C, Michalski M-C. Vegetable lecithins: a review of their compositional diversity, impact on lipid metabolism and potential in cardiometabolic disease prevention. Biochimie. 2020; 169: 121–132. https://doi.org/10.1016/j.biochi.2019.11.017

Jung Y-G, Lee C-R, Kim H-J, Kim Min-G, Jin KS, Lee H-Y. Effect of hydrocarbon chain length of aliphatic solvents on the reverse self-assembly of lecithin and monovalent ion mixtures. Colloids Surf A Physicochem Eng Asp. 2020; 607: 125441. https://doi.org/10.1016/j.colsurfa.2020.125441

Tung SH, Huang YE, Raghavan SR. A new reverse wormlike micellar system: mixtures of bile salt and lecithin in organic liquids. J Am Chem Soc. 2006; 128: 5751–5756. https://doi.org/10.1021/ja0583766

Kumar R, Katare OP. Lecithin organogels as a potential phospholipid-structured system for topical drug delivery: a review. AAPS PharmSciTech. 2005; 6: 298–310. https://doi.org/10.1208/pt060240

Zou H, Zhao N, Li S, Sun S, Dong X, Yu C. Physicochemical and emulsifying properties of mussel water-soluble proteins as affected by lecithin concentration. Int J Biol. Macromol. 2020; 163: 180–189. https://doi.org/10.1016/j.ijbiomac.2020.06.225

Amiri-Rigi A., Abbasi S. Extraction of lycopene using a lecithin-based olive oil microemulsion. Food Chem. 2018; 272: 568–573. https://doi.org/10.1016/j.foodchem.2018.08.080

Shen Y, Chang C, Shi M, Su Y, Gu L, Li J, Yang Y. Interactions between lecithin and yolk granule and their influence on the emulsifying properties. Food Hydrocoll. 2019; 101: 105510. https://doi.org/10.1016/j.foodhyd.2019.105510

Xue J, Zhong Q. Thyme oil nanoemulsions coemulsified by sodium caseinate and lecithin. J Agric Food Chem. 2014; 62: 9900–9907. https://doi.org/10.1021/jf5034366

Đorđević BS., Todorović ZB, Troter DZ, Stanojević LjP, Veljković VB. Extraction of quercetin from waste onion (Allium cepa L.) tunic by the aqueous solutions of different deep eutectic solvents. Adv Technol. 2018; 7: 5–10. https://doi.org/10.5937/SavTeh1802005d

Veljković VB, Stamenković OS, Todorović ZB, Lazić ML, Skala DU. Kinetics of sunflower oil methanolysis catalyzed by calcium oxide. Fuel. 2009; 88: 1554–1562. https://doi.org/10.1016/j.fuel.2009.02.013

Stamenkoviæ OS, Rajkoviæ K, Velièkoviæ AV, Miliæ PS, Veljkoviæ VB. Optimization of base-catalyzed ethanolysis of sunflower oil by regression and artificial neural network models. Fuel Process Technol. 2013; 114: 101–108. https://doi.org/10.1016/j.fuproc.2013.03.038

Veličković AV, Stamenković OS, Todorović ZB, Veljković VB. Application of the full factorial design to optimization of base–catalyzed sunflower oil ethanolysis. Fuel. 2013; 104: 433–442. https://doi.org/10.1016/j.fuel.2012.08.015

Constantin V, Adya AK, Popescu A-M. Density, transport properties and electrochemical potential windows for the 2-hydroxy-N,N,N-trimethylethanaminium chlorides based ionic liquids at several temperatures. Fluid Phase Equilib. 2015; 395: 58–66. https://doi.org/10.1016/j.fluid.2015.03.025

Mitar A, Panić M, Prlić Kardum J, Halambek J, Sander A, Zagajski Kučan K, Radojčić Redovniković I, Radošević K. Physicochemical properties, cytotoxicity, and antioxidative activity of natural deep eutectic solvents containing organic acid. Chem Biochem Eng Q. 2019; 33: 1–18. https://doi.org/10.15255/CABEQ.2018.1454

Troter DZ, Todorović ZB, Đokić–Stojanović DR, Đordević BS, Todorović VM, Konstantinović SS, Veljković VB. The physicochemical and thermodynamic properties of the choline chloride-based deep eutectic solvents. J Serbian Chem Soc. 2017; 82: 1039–1052. https://doi.org/10.2298/jsc170225065t

Ramón DJ, Guillena G. Deep Eutectic Solvents: Synthesis, Properties, and Applications, John Wiley & Sons; 2020; 1–21.

Siongco KR, Leron RB, Li M-H. Densities, refractive indices, and viscosities of N,N-diethylethanol ammonium chloride-glycerol or -ethylene glycol deep eutectic solvents and their aqueous solutions. J Chem Thermodyn. 2013; 65: 65–72. https://doi.org/10.1016/j.jct.2013.05.041

Jibril B, Mjalli F, Naser J, Gano Z. New tetrapropylammonium bromide–based deep eutectic solvents: Synthesis and characterizations. J Mol Liq. 2014; 199: 462–469. https://doi.org/10.1016/j.molliq.2014.08.004

AlOmar MK, Hayyan M, Alsaadi MA, Akib S, Hayyan A, Hashim MA. Glycerol–based deep eutectic solvents: Physical properties. J Mol Liq. 2016; 215: 98–103. https://doi.org/10.1016/j.molliq.2015.11.032

Lapeña D, Lomba L, Artal M, Lafuente C, Giner B. The NADES glyceline as a potential green Solvent: A comprehensive study of its thermophysical properties and effect of water inclusion. J Chem Thermodyn. 2019; 128: 164–172. https://doi.org/10.1016/j.jct.2018.07.031

Bahadori L, Chakrabarti MH, Mjalli FS, AlNashef IM, Manan NSA, Hashim MA. Physicochemical properties of ammonium–based deep eutectic solvents and their electrochemical evaluation using organometallic reference redox systems. Electrochim Acta, 2013; 113: 205–211. https://doi.org/10.1016/j.electacta.2013.09.102

Troter DZ, Zlatković MZ, Đokić-Stojanović DR, Konstantinović SS, Todorović ZB. Citric acid-based deep eutectic solvents: Physical properties and their use as cosolvents in sulphuric acid-catalysed ethanolysis of oleic acid. Adv Technol. 2016; 5: 53–65. https://doi.org/10.5937/savteh1601053t

Glasser L. Thermodynamic estimation: Ionic materials. J Solid State Chem. 2013; 206: 139–144. https://doi.org/10.15744/2348-9812.1.e105

Haynes WM. CRC Handbook of chemistry and physics, A ready reference book of chemical and physical data, 94th ed., CRC Press, Taylor & Francis Group, Boca Raton, FL; 2013; pp. 12–21.

Hayyan A, Mjalli FS, AlNashef IM, Al-Wahaibi YM, Al-Wahaibi T, Hashim MA. Glucose-based deep eutectic solvents: Physical properties. J Mol Liq. 2013; 178: 137. https://doi.org/10.1016/j.molliq.2012.11.025

Born M, Wolf E. Principles of optics: electromagnetic theory of propagation, interference and diffraction of light, 7th Expanded Edition, Cambridge University Press, United Kingdom; 1999; pp. 11–14.

Ghaedi H, Ayoub M, Sufian S, Shariff AM, Lal B, Wilfred CD. Density and refractive index measurements of transition-temperature mixture (deep eutectic analogues) based on potassium carbonate with dual hydrogen bond donors for CO2 capture. J Chem Thermodyn. 2018; 118: 147. https://doi.org/10.1016/j.jct.2017.11.008

Wu TY, Su S-G, Lin YC, Wang HP, Lin MW, Gung ST, Sun IW. Electrochemical and physicochemical properties of cyclic amine-based Brønsted acidic ionic liquids. Electrochim Acta. 2010; 56: 853–862. https://doi.org/10.1016/j.electacta.2010.09.084

Đorđević BS, Troter DZ, Veljković VB, Kijevčanin MLj, Radović IR, Todorović ZB. The physicochemical properties of the deep eutectic solvents with triethanolamine as a major component. J Serb Chem Soc. 2020; 85: 1303–1315. https://doi.org/10.2298/JSC200425050D

Esipovich A, Danov S, Belousov A, Rogozhin A. Improving methods of CaO transesterification activity. J Mol Catal A Chem. 2014; 395: 225–233. https://doi.org/10.1016/j.molcata.2014.08.011

Veličković AV, Avramović JM, Stamenković OS, Veljković VB. Kinetics of the sunflower oil ethanolysis using CaO as catalyst. Chem Ind Chem Eng Q. 2016; 22: 409–418. https://doi.org/10.2298/ciceq160106003v

Huang W, Tang S., Zhao H, Tian S. Activation of commercial CaO for biodiesel production from rapeseed oil using a novel deep eutectic solvent. Ind Eng Chem Res. 2013; 52: 11943–11947. https://doi.org/10.1021/ie401292w

Manurung R, Ramadhani DA, Maisarah S. One step transesterification process of sludge palm oil (SPO) by using deep eutectic solvent (DES) in biodiesel production. AIP Conf. Proc. 2017; 1855: 070004. https://doi.org/10.1063/1.4985531

Manurung R, Winarta A, Taslim Indra L. Biodiesel production from ethanolysis of palm oil using deep eutectic solvent (DES) as cosolvent, IOP Conf. Ser.: Mater. Sci. Eng. 2017; 206: 012023. https://doi.org/10.1088/1757-899X/206/1/012023

di Bitonto L, Reynel-Avila HE, Mendoza-Castillo DI, Bonilla-Petriciolet A, Duran-Valle CJ, Pastore C. Synthesis and characterization of nanostructured calcium oxides supported onto biochar and their application as catalysts for biodiesel production. Renew Energy. 2020; 160: 52–66. https://doi.org/10.1016/j.renene.2020.06.045

Chen X, Li Z, Chun Y, Yang F, Xu H, Wu X. Effect of the formation of diglycerides/monoglycerides on the kinetic curve in oil transesterification with methanol catalyzed by calcium oxide. ACS Omega. 2020; 5: 4646−4656. https://doi.org/10.1021/acsomega.9b04431

Ramos M, Dias A PS, Teodoro F. Soybean oil ethanolysis over Ca based catalyst. Statistical optimization of reaction conditions. React Kinet Mech Catal. 2020; 130: 433–445. https://doi.org/10.1007/s11144-020-01791-y

Sánchez-Cantú M, Reyes–Cruz FM, Rubio–Rosas E, Pérez–Díaz LM, Ramírez E, Valente JS. Direct synthesis of calcium diglyceroxide from hydrated lime and glycerol and its evaluation in the transesterification reaction. Fuel. 2014; 138: 126–133. https://doi.org/10.1016/j.fuel.2014.08.006

Kouzu M, Hidaka J, Wakabayashi K, Tsunomori M. Solid base catalysis of calcium glyceroxide for a reaction to convert vegetable oil into its methyl esters. Appl Catal A: Gen. 2010; 390: 11–18. https://doi.org/10.1016/j.apcata.2010.09.029

Rodriguez–Navarro C, Vettori I, Ruiz–Agudo E. Kinetics and mechanism of calcium hydroxide conversion into calcium alkoxides: implications in heritage conservation using nanolimes. Langmuir. 2016; 32: 5183–5194. https://doi.org/10.1021/acs.langmuir.6b01065

Soares Dias AP, Ramos M, Catarino M, Puna J, Gomes J. Solvent assisted biodiesel production by co-processing beef tallow and soybean oil over calcium catalysts. Waste Biomass Valorization. 2019; 11: 6249–6259. https://doi.org/10.1007/s12649-019-00903-7