THE INFLUENCE OF MOISTURE CONTENT ON DRILLED CUTTINGS’ PROPERTIES OF BED PACKING AND FLOWABILITY

Original scientific paper

DOI:

https://doi.org/10.2298/CICEQ230424023AKeywords:

Particle aggregation, particle disaggregation, packed bed, flowability, compactionAbstract

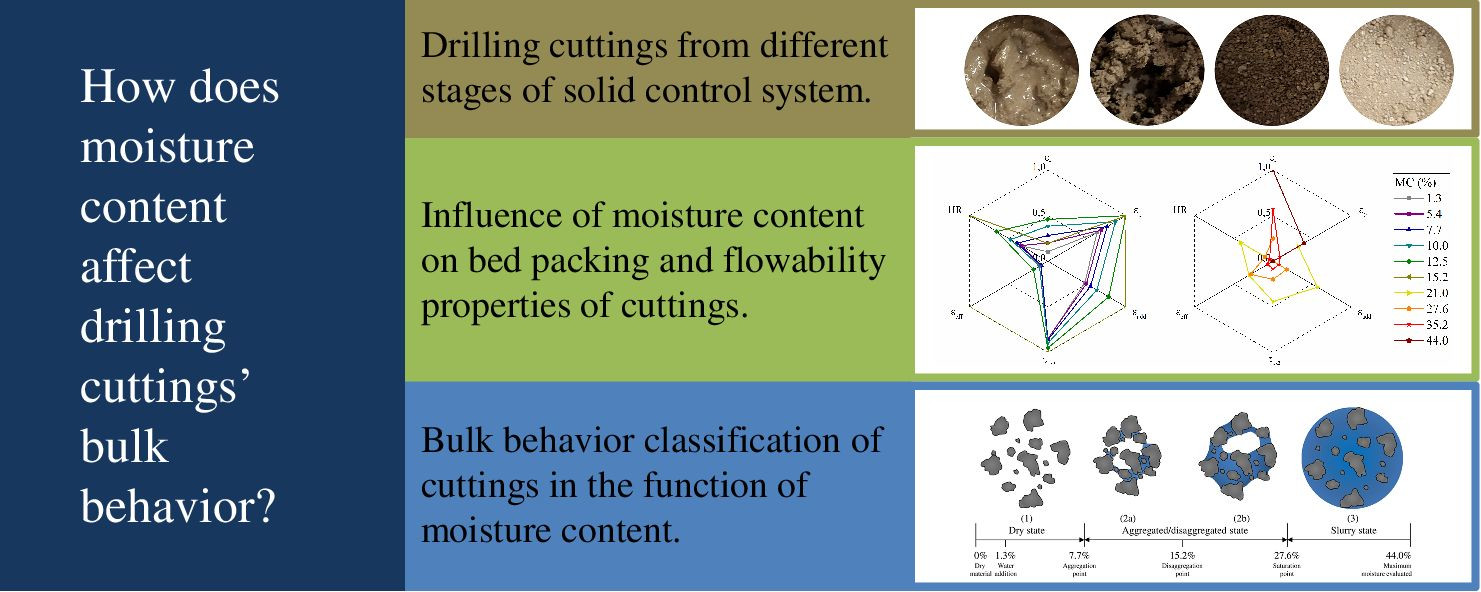

To design and operate various equipment of the solids control system in offshore drilling platforms, it is important to establish how the moisture content influences the characteristics of drilled cuttings to form packed beds and flow over solid surfaces. The current study comprehensively analyzes how moisture content, primarily composed of water and representing water-based muds (WBMs), influences the bed packing properties and drilled cuttings' flowability. The particle aggregation/disaggregation dynamics, loose and tapped bulk densities and porosities, compaction dynamics of packed beds, Hausner ratio, and angle of repose of drilled cuttings with ten distinct moisture contents (1.4—44.0 wt%) were analyzed. It was noticed that the increment of moisture content up to 15.2% promoted the formation of looser interparticle structures. However, these structures were steadier, showing greater difficulty flowing and releasing air/liquid. The continuous increment of moisture content beyond 15.2% promoted a complete change in the material behavior. The interparticle structures became denser. The material could flow and release air/liquid more easily. In addition, it was possible to establish a classification of the different behaviors of drilled cuttings according to the moisture content. Predictive models were proposed to describe the influence of the moisture content on the bed packing and flowability properties of drilled cuttings.

References

EnscoRowan, Offshore Market Recovery, EnscoRowan, Houston (2019), p. 28. https://www.valaris.com/home/default.aspx.

C. Apostolidou, E. Sarris, A. Georgakopoulos, J. Pet. Sci. Eng. 208 (2022) 109758. https://doi.org/10.1016/j.petrol.2021.109758.

A.K. Alkalbani, G.T. Chala, A.M. Alkalbani, Ain Shams Eng. J. 14 (2023) 102147. https://doi.org/10.1016/j.asej.2023.102147.

IOGP, Drilling waste management technology review, The International Association of Oil & Gas Producer, London (2016), p. 102. https://www.iogp.org/bookstore/product/drilling-waste-management-technology-review/.

S. Seaton, R.G. Morris, SPE/EPA/DOE Exploration and Production Environmental Conference, in Proceeding of SPE/EPA/DOE Exploration and Production Environmental Conference, Galveston, USA (2005) p. 157—164. https://doi.org/10.2118/94194-MS.

G.A. Burnett, C. Crabb, D. Wood, K.W. Seyfert, J.M. McIntosh, US 2006/0102390A1 (2006).

G.A. Burnett, C. Crabb, D. Wood, K. Seyffert, J. McIntosh, US 20070215386A1 (2007).

G.A. Burnett, D. Wood, K.W. Seyffert, W.C. Herben, J.M. Mcintosh, C. Crabb, US 7195084B2 (2007).

G.A. Burnett, D. Wood, K.W. Seyffert, W.C. Herben, J.M. Mcintosh, C. Crabb, EP 1766181B1 (2011).

G.A. Burnett, D. Wood, K.W. Seyffert, W.C. Herben, J.M.

Mcintosh, C. Crabb, WO 2005/124096Al (2004).

G.A. Burnett, C. Crabb, D. Wood, K.W. Seyffert, J. Mcintosh, EP 2165951A1 (2011).

D. Mills, Pneumatic Conveying Design Guide, Elsevier, Oxford (2004) p. 650.

G.E. Klinzing, F. Rizk, R. Marcus, L.S. Leung, Pneumatic Conveying of Solids: A Theoretical and Practical Approach, Springer, New York (2010) p. 600. https://doi.org/10.1080/07373939308916871.

J.P. Robinson, S.W. Kingman, C.E. Snape, S.M. Bradshaw, M.S.A. Bradley, H. Shang, R. Barranco, Chem. Eng. Res. Des. 88 (2010) 146—154. https://doi.org/10.1016/j.cherd.2009.07.011.

R. Pesic, T. Kaludjerovic-Radoicic, N. Boskovic-Vragolovic, Z. Arsenijevic, Z. Grbavcic, Chem. Ind. Chem. Eng. Q. 21 (2015) 419—427. https://doi.org/10.2298/CICEQ140618044P.

D. Schulze, Powders and Bulk Solids, Springer, New York (2008) p. 516. 978-3-540-73768-1.

A. Crouter, L. Briens, AAPS PharmSciTech 15 (2014) 65—74. https://doi.org/10.1208/s12249-013-0036-0.

T.O. Althaus, E.J. Windhab, Powder Technol. 215–216 (2012) 59—65. https://doi.org/10.1016/j.powtec.2011.09.007.

P. Pierrat, H.S. Caram, Powder Technol. 91 (1997) 83—93. https://doi.org/10.1016/S0032-5910(96)03179-8.

H.G. Kristensen, Adv. Pharm. Sci. 7 (1995) 221—272. https://doi.org/10.1016/S0065-3136(06)80006-3.

K.P. Panayiotopoulos, C.E. Mullins, J. Soil Sci. 36 (1985) 129—139. https://doi.org/10.1111/j.1365-2389.1985.tb00318.x.

H. Kalman, D. Portnikov, Powder Technol. 381 (2021) 285—297. https://doi.org/10.1016/j.powtec.2020.12.019.

API, Recommended Practice for Field Testing Oil-Based Drilling Fluids: API Recommended Practice 13B-2, Washington (2012), p. 67.

ASTM, Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates (C136-06), ASTM International, West Conshohocken (2015), p. 5. https://doi.org/10.1520/C0136_C0136M-14.

P.A. Vesilind, Resour. Recover. Conserv. 5 (1980) 275—277. https://doi.org/10.1016/0304-3967(80)90007-4.

ASTM, Standard test methods for determining loose and tapped bulk densities of powders using a graduated cylinder (D7481-18), American Society for Testing and Materials, (2018), p. 4. https://doi.org/10.1520/D7481-18.

USP, The United States Pharmacopeia: the National Formulary, United States Pharmacopeia Convenction, Rockville (2018), p. 1136.

H.O.N. Altino, G.A. Lourenço, C.H. Ataíde, Powder Technol. 391 (2021) 184—197. https://doi.org/10.1016/j.powtec.2021.06.013.

K. Traina, R. Cloots, S. Bontempi, G. Lumay, N. Vandewalle, F. Boschini, Powder Technol. 235 (2013) 842—852. https://doi.org/10.1016/j.powtec.2012.11.039.

ASTM, Standard Test Method for Measuring the Angle of Repose of Free-Flowing Mold Powders (C1444-00), American Society for Testing and Materials, (2000). p. 4. https://doi.org/10.1520/C1444-00.

WHO. Bulk density and tapped density of powders (WHOdocument QAS/11.450), WorldHealth Organization, Dept. of Essential Medicines and Pharmaceutical Policies, (2012).

K. Ishizaki, S. Komarneni, M. Nanko, Porous Materials, Springer, Boston (1998), p. 249. https://doi.org/10.1007/978-1-4615-5811-8.

C. Hyun, S. Shah, S. Osisanya, SPE Annual Technical Conference and Exhibition, in Proceeding of the SPE Annual Technical Conference and Exhibition, Dallas, USA (2000), p. 905—918. https://doi.org/10.2523/63269-MS.

I. Petri, M.S. Pereira, J.M. dos Santos, C.R. Duarte, C.H. Ataíde, C.M. d. Á. Panisset, J. Pet. Sci. Eng. 134 (2015) 23—29. https://doi.org/10.1016/j.petrol.2015.07.022.

D. Geldart, Powder Technol. 7 (1973) 285—292. https://doi.org/10.1016/0032-5910(73)80037-3.

R.J. Reeder, Carbonates: Mineralogy and Chemistry, Stony Book, New York (1983), p. 394. https://doi.org/10.1515/9781501508134.

H.G. Kristensen, T. Schaefer, Drug Dev. Ind. Pharm. 13 (1987) 803—872. https://doi.org/10.3109/03639048709105217.

A. Singer, Z. Barakat, S. Mohapatra, S.S. Mohapatra, Nanocarriers Drug Deliv. (2019) 395—419. https://doi.org/10.1016/b978-0-12-814033-8.00013-8.

S. Golubić, J. Schneider, in Biogeochemical Cycling of Mineral-Forming, P.A. Trudinger and D.J. Swaine, Elsevier, (1979) Amsterdam, p. 122. https://doi.org/10.1016/S0166-1116(08)71056-2.

P. Philippe, D. Bideau, Europhys. Lett. 60 (2002) 677—683. https://doi.org/10.1209/epl/i2002-00362-7.

H. Lu, X. Guo, Y. Jin, X. Gong, Chem. Eng. Res. Des. 133 (2018) 326—334. https://doi.org/10.1016/j.cherd.2018.03.023.

S. Gaisford, M. Saunders, Essentials of Pharmaceutical Preformulation, John Wiley & Sons, Chichester (2012), p. 252. https://doi.org/10.1002/9781118423226.

H. Kalman, Powder Technol. 393 (2021) 582—596. https://doi.org/10.1016/j.powtec.2021.08.010.

D. Geldart, E.C. Abdullah, A. Hassanpour, L.C. Nwoke, I. Wouters, Chin. Particuol. 4 (2006) 104—107. https://doi.org/10.1016/s1672-2515(07)60247-4.

H. Kalman, D. Portnikov, Powder Technol. 381 (2021) 477—487. https://doi.org/10.1016/j.powtec.2020.12.014.

I.M.F. Wouters, D. Geldart, Part. Part. Syst. Charact. 13 (1996) 254—259. https://doi.org/10.1002/ppsc.19960130408.

H. Kalman, Powder Technol. 382 (2021) 573—593. https://doi.org/10.1016/j.powtec.2021.01.012.

Downloads

Published

Issue

Section

License

Copyright (c) 2023 Heitor Otacílio Nogueira Altino, Giovani Aud Lourenço, Carlos Henrique Ataíde, Claudio Roberto Duarte

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.