EFFECTS OF ADDING DIFFERENT QUANTITIES OF YEAST AND CHOKEBERRY JUICE ON FERMENTATION OF MEAD

Scientific paper

DOI:

https://doi.org/10.2298/CICEQ220325022MKeywords:

antimicrobial activity, antioxidant activity, aronia, fermentation rate, netic model, meadAbstract

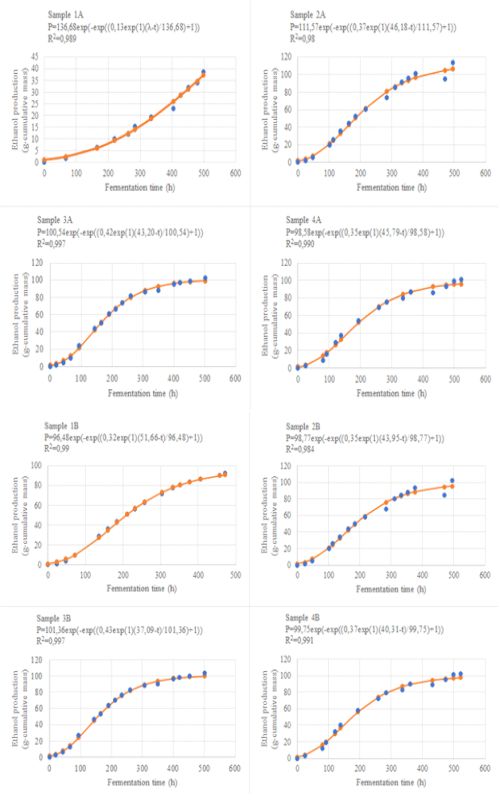

Honey is a product of high nutritional value, used as a raw material for obtaining mead. However, adding fruit juices, including chokeberry juice, can improve mead quality. This paper aims to assess the effects that adding different quantities of chokeberry juice, with the variation of 3 amounts of inoculated yeast, has on the fermentation and physicochemical, antioxidant, and antimicrobial properties of mead. The parameters analyzed are the dry matter content, pH value, and content of volatile acids, ethanol and methanol, total phenols and flavonoids, FRAP, DPPH, and ABTS tests, and antimicrobial properties. The results obtained in this paper show that adding chokeberry juice improves the antioxidant properties of the final product and positively affects the course of mead fermentation, i.e., it has led to an increase in the maximum concentration of ethanol. Regarding the chemical composition of mead, there is no significant difference, except in the obtained ethanol content, which is the highest in samples with 10% of added chokeberry juice. Furthermore, the control sample showed the best antimicrobial activity, while the sample with 5% added chokeberry juice showed the weakest effect. Finally, the strongest effect was seen in the sample with 20% of added chokeberry juice.

References

Codex Standard for Honey 12-1981, Rev.1 (1987), Rev. 2 (2001)1 https://alimentosargentinos.magyp.gob.ar/contenido/marco/Codex_Alimentarius/normativa/codex/stan/CODEX_STAN_12.htm.

A. Wilczyńska, Polish J. Food Nutr. Sci. 60 (2010) 309—313. http://journal.pan.olsztyn.pl/pdf- 98274- 31027?filename=PHENOLIC%20CONTENT%20AND.pdf.

M. Bucekova, M. Buriova, L. Pekarik, V. Majtan, J. Majtan, Sci. Rep. 8 (2018) 1—9. https://doi.org/10.1038/s41598-018-27449-3.

D. Šmorgovičová, P. Nádaský, R. Tandlich, B.S. Wilhelmi, G. Cambray, Czech J. Food Sci. 30 (2012) 241—246. https://doi.org/10.17221/113/2011-CJFS.

G.I. Dezmirean, L.A. Mărghitaş, O. Bobiş, D.S. Dezmirean, V. Bonta, S. Erler, J. Agric. Food Chem. 60 (2012) 8028—8035. https://doi.org/doi.org/10.1021/jf3022282.

Y. Teramoto, R. Sato, S. Ueda, Afr. J. Biotechnol. 4 (2005) 160—163. https://doi.org/10.4314/AJB.V412.15072.

P. Vargas, R. Gulling, Making Wild Wines & Meads, Storey Publishing, United States (1999), p.122 ISBN: 1580171826.

A. Savić, A. Velemir, S. Papuga, M. Stojković, Foods Raw

Mater. 9 (2021) 146—152. https://doi.org/10.21603/2308-4057-2021-1-146-152.

A. Iglesias, A. Pascoal, A.B. Choupina, C.A. Carvalho, X. Feás, L.M. Estevinho, Molecules 19 (2014) 12577—12590. https://doi.org/10.3390/molecules190812577.

J. Šnebergová, H. Čižková, E. Neradová, B. Kapci, A. Rajchl, M. Voldřich, Czech J. Food Sci. 32 (2014) 25—30. https://doi.org/10.17221/540/2012-CJFS.

P. Denev, M. Číž, M. Kratchanova, D. Blazheva, Food Chem. 284 (2019) 108—117. https://doi.org/10.1016/j.foodchem.2019.01.108.

A. Bataraga, V. Valkovska, Key Eng. Mater. 850 (2020) 184-189. https://doi.org/10.4028/www.scientific.net/KEM.850.184.

M.J. Dodić, D.G. Vučurović, S.N. Dodić, J.A. Grahovac, S.D. Popov, N.M. Nedeljković, Appl. Energy 99 (2012) 192—197. https://doi.org/10.1016/j.apenergy.2012.05.016.

H.S. Lakićević, I.T. Karabegović, N.Č. Nikolić, M.G. Petrović, S.A. Đorđević, L.M. Lazić, Adv. Technol. 7 (2018) 11—18. https://doi.org/10.5937/SavTeh1802011L.

International Code of Oenological Practices. International Organisation of Vine and Wine, Paris (2021) https://www.oiv.int/sites/default/files/publication/2022-10/International%20Code%20of%20oenlogical%20practices.pdf.

M.L. Wang, Y.M. Choong, N.W. Su, M.H. Lee, J. Food Drug Anal. 11 (2003) 133—140. https://doi.org/10.38212/2224-6614.2710.

K. Wolfe, R.H. Liu, J. Agric. Food Chem. 51 (2003) 1676—1683. https://doi.org/10.1021/jf020782a.

A.A.L. Ordonez, J.D. Gomez, M.A. Vattuone, M.I. Isla, Food Chem. 97 (2006) 452—458. https://doi.org/10.1016/j.foodchem.2005.05.024.

W. Brand-Williams, M.E. Cuvelier, C. Barset, LWT – Food Sci. Technol. 28 (1995) 25—30. https://doi.org/10.1016/S0023-6438(95)80008-5.

R. Re, N. Pellegrini, A. Proteggente, A. Pannala, M. Yang, C. Rice-Evans, Free Radical. Biol. Med. 26 (1999) 1231—1237. https://doi.org/10.1016/s0891-5849(98)00315-3.

I.F.F. Benzie, J.J. Strain, Anal. Biochem. 239 (1996) 70—76. https://doi.org/10.1006/abio.1996.0292.

M. Balouiri, M. Sadiki, S.K. Ibnsouda, J. Pharm. Anal. 6 (2016) 71—79. https://doi.org/10.1016/j.jpha.2015.11.005.

Determination of minimum inhibitory concentrations of antibacterial agents by agar dilution, EUCAST (2000). https://doi.org/10.1046/j.1469-0691.2000.00142.x.

N.N. Verović, MSc Thesis, University of Niš (in Serbian) (2018) https://www.pmf.ni.ac.rs/download/master/master_radovi_geografija/geografija_master_radovi/2018/2018-10-30-vn.pdf.

A.P. Pereira, A. Mendes-Ferreira, J.M. Oliveira, L.M. Estevinho, A. Mendes-Faia, Food Microbiol. 33 (2013) 114—123. https://doi.org/10.1016/j.fm.2012.09.006.

P. Sroka, P. Satora, Food Hydrocolloids 63 (2017) 233—239. https://doi.org/10.1016/j.foodhyd.2016.08.044.

A.M. Martínez, G.J. Vivas, M.C. Quicazán, Chem. Eng. Trans. 49 (2016) 19—24. https://doi.org/10.3303/CET1649004.

S.S.D. Mohammed, B. Yohanna, J.R. Wartu, N.L. Abubakar, S. Bello, Int. J. Biol. Sci. 10 (2018) 52—61. https://doi.org/10.5539/ijb.v10n3p52.

A. Mendes-Ferreira, F. Cosme, C. Barbosa, V. Falco, A. Inês, A. Mendes-Faia, Int. J. Food Microbiol. 144 (2010) 193—198. https://doi.org/10.1016/j.ijfoodmicro.2010.09.016.

P. Sroka, T. Tuszyński, Food Chem. 104 (2007) 1250—1257. https://doi.org/10.1016/j.foodchem.2007.01.046.

A.P. Pereira, A. Mendes-Ferreira, L.M. Estevinho, A. Mendes-Faia, J. Inst. Brew. 121 (2015) 405—410. https://doi.org/10.3390/microorganisms7100404.

J. Kawa-Rygielska, K. Adamenko, A.Z. Kucharska, K. Szatkowska, Food Chem. 283 (2019) 19—27. https://doi.org/10.1016/j.foodchem.2019.01.040.

H. Akalin, M. Bayram, R.E. Anli, J. Inst. Brew. 123 (2017) 167—174. https://doi.org/10.1002/jib.396.

M. Bely, I. Masneuf-Pomarède, D. Dubourdieui, J. Int. Sci. Vigne Vin 39 (2005) 191—197. https://doi.org/.20870/oeno-one.2005.39.4.886.

C.H. Chen, Y.L. Wu, D. Lo, M.C. Wu, J. Inst. Brew. 119 (2013) 303—308. https://doi.org/10.1002/jib.95.

A.P. Pereira, A. Mendes-Ferreira, J.M. Oliveira, L.M. Estevinho, A. Mendes-Faia, Food Microbiol. 33 (2013) 114—123. https://doi.org/10.1016/j.fm.2012.09.006.

K. Adamenko, J. Kawa-Rygielska, A.Z. Kucharska, N. Piórecki, Molecules 23 (2018) 2024—2037. https://doi.org/10.3390/molecules23082024.

T. Gomes, T. Dias, V. Cadavez, J., Verdial, J. S. Morais, E. Ramalhosa, L.M. Estevinho, Pol. J. Food Nutr. Sci. 65 (2015) 137—142. https://doi.org/10.1515/pjfns-2015-0006.

K.A. Roni, D. Kartika, H. Apriyadi, N. Herawati, J. Comput. Theor. Nanosci. 16 (2019) 5228—5232. https://doi.org/10.1166/jctn.2019.8591.

S. Czabaj, J. Kawa-Rygielska, A.Z. Kucharska, J. Kliks, Molecules 22 (2017) 803—818. https://doi.org/10.3390/molecules22050803.

U. Miljić, Ph.D. Thesis, University of Novi Sad (in Serbian) (2015) https://nardus.mpn.gov.rs/handle/123456789/1815?locale-attribute=sr_RS.

A.C. Şarba, Ph.D. Thesis, University of Cluj-Napoca (2015) (in English) www.usamvcluj.ro/en/files/teze/en/2015/Şarba.pdf.

D. Kahoun, S. Řezková, K. Veškrnová, J. Královský, M. Holčapek, J. Chromatogr. A 1202 (2008) 19—33. https://doi.org/10/1016/j.chroma.2008.06.016.

J.N. Eloff, I.E. Angeh, L.J. McGaw, Ind. Crop. Prod. 110 (2017) 103—112. https://doi.org/10.1016/j.indcrop.2017.11.014.

J.N. Eloff, BMC Complementary Altern. Med. 19 (2019) 106—114. https://doi.org/10.1186/s12906-019-2519-3.

M. Stojković, D. Cvetković, A. Savić, Lj. Topalić-Trivunović, A. Velemir, S. Papuga, M. Žabić, J. Food Sci. Technol. 58 (2021) 2555—2566. https://doi.org/10.1007/s13197-020-04762-2.

P.C. Molan, Bee World 73 (1992) 5—28. https://doi.org/10.1080/0005772X.1992.11099109.

S. Bogdanov, LWT- Food Sci. Technol. 30 (1997) 748—753.

https://doi.org/10.1016/fstl.1997.0259.

F.J. Leyva-Jimeneza, J. Lozano-Sanchez, I. Borras-Linares, M.L. Cadiz-Gurrea, E. Mahmoodi-Khaledi, LWT-Food Sci. Technol. 101 (2019) 236—245. https://doi.org/10.1016/j.lwt.2018.11.015.

M. Fikselova, M. Kačaniova, L. Hleba, M. Mellen, N. Vučković, M. Dzugan, Anim. Sci. Biotechnol. 47 (2014) 218—224. https://web.archive.org/web/20180502025911id_/http://www.spasb.ro/index.php/spasb/article/viewFile/1697/1722.

N.Z. Srećković, V.B. Mihailović, J.S. Katanić-Stanković, Kragujev. J. Sci. 41 (2019) 53—68. https://doi.org/10.5937/KgJSci1941053S.

M.E. Weise, B. Eberly, D.A. Person, BMJ 311 (1995) 1657—1660. https://doi.org/10.1136/bmj.311.7021.1657.

M.J.R. Vaquero, M.R. Alberto, M.C.M. de Nadra, Food Control 18 (2007) 93—101. https://doi.org/10.1016/j.f00dc0nt.2005.08.010.

A. Radovanović, B. Radovanović, B. Jovančićević, Food Chem. 117 (2009) 326—331. https://doi.org/10.1016/j.foodchem.2009.04.008.

J.J. Vulić, T.N. Cebović, V.M. Candanović, G.S. Cetković, S.M. Đilas, J.M. Candanović-Brunet, J.M. Velićanski, D.D. Cvetković, V.T. Tumbas, Food Funct. 4 (2013) 713—721. https://doi.org/10.1039/c3fo30315b.

N.K. Steth, T.R. Wisniewski, T.R. Franson, Am. J. Gastroenterol. 83 (1988) 658—660. https://pubmed.ncbi.nlm.nih.gov/3287903/.

H. Arima, H. Ashida, G. Danno, Biosci. Biotechnol. Biochem. 66 (2002) 1009—1014. https://10.1271/bbb.66.1009.

N. Boban, M. Tonkic, D. Budimir, D. Modun, D. Sutlovic, V. Punda-Polic, M. Boban, J. Food Sci. 75 (2010) 322—326. https://10.1111/j.1750-3841.2010.01622.x.

J. Krisch, G. László, M. Tölgyesi, T. Papp, C. Vágvölgyi, Acta Biol. (Szeged) 52 (2008) 267—270. https://abs.bibl.u-szeged.hu/index.php/abs/article/view/2639/2631.

T. Krstić, Ph.D. Thesis, University of Novi Sad (in Serbian) (2018) https://nardus.mpn.gov.rs/handle/123456789/11068.

Downloads

Published

Issue

Section

License

Copyright (c) 2021 Maja Milijaš, Dragoljub Cvetković, Aleksandar Savić, Ana Velemir, Ljiljana Topalić-Trivunović, Saša Papuga

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.