ENERGY SAVING IN OILFIELDS BY USING WASTE HEAT IN THE DISPOSED WATER

Scientific paper

DOI:

https://doi.org/10.2298/CICEQ211201019SKeywords:

viscosity reduction, shipping pumps, crude oil, simulation, DesalterAbstract

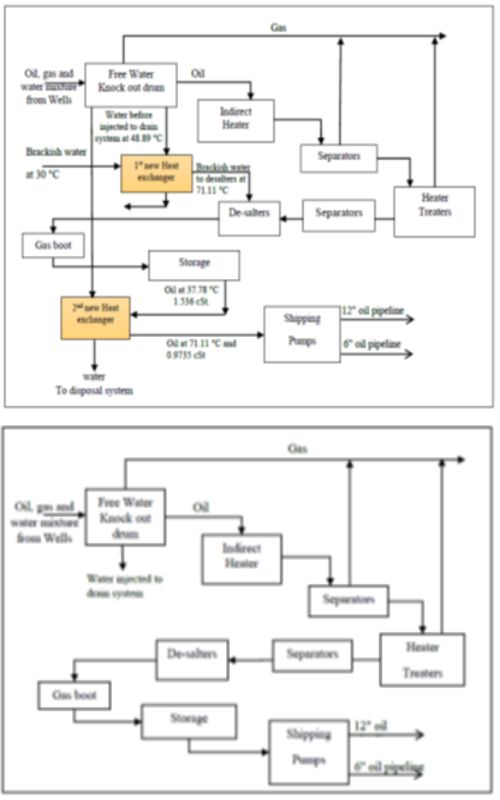

The present work aims to retrofit an existing Egyptian oilfield plant to improve desalter performance and reduce the power of crude oil shipping pumps. In this work, waste heat in disposed water that represents a value is used in heating brackish water injected over desalter and in heating crude oil before shipping. ASPEN HYSYS version 11 simulation software was used. The retrofit of the considered oilfield plant is based on the implementation of two new heat exchangers to recover waste heat in the disposed water. The results showed that using waste heat to heat the brackish water in the desalter from 30 °C to 71.11 °C will increase the operating temperature of the desalter and thus increase the sedimentation and separation rate. On the other hand, using waste heat in heating the crude oil before shipping from 37.78 °C to 71.11 °C reduces the oil viscosity from 1.536 cSt to 0.9735 cSt. Reducing the viscosity of the crude oil will reduce the pressure drop of the shipping pumps, and therefore the power required to pump the oil will be reduced. The presented retrofit design can be used as a guide in upgrading existing plants and plants under the design phase.

References

A. Hart, J. Pet. Explor. Prod. Technol. 4 (3) (2014) 327—336. https://doi.org/10.1007/s13202-013-0086-6.

Y. Al-Roomi, R. George , A. Elgibaly, A. Elkamel, J. Pet. Sci. Eng. 42 (2–4) (2004) 235—243. https://doi.org/10.1016/j.petrol.2003.12.014.

R. Martinez-Palou, M.D.L. Mosqueira, B. Zapata-Rendon, E. Mar-Juarez, C. Bernal-Huicochea, J. de la Cruz Clavel-López, J. Aburto, J. Pet. Sci. Eng. 75 (3—4) (2011) 274—282. https://doi.org/10.1016/j.petrol.2010.11.020.

A. Saniere, I. Henaut, J.F. Argillier, Oil Gas Sci. Technol. 59 (5) (2004) 455—466. https://doi.org/10.2516/ogst:2004031.

R.I. Ibrahim, M.K. Odah, A. Al-Mufti, IOP Conf. Ser.: Mater. Sci. Eng. 579 (1) (2019) 012054. https://doi.org/10.1088/1757-899X/579/1/012054.

R.G. Santos, W. Loh, A. C. Bannwart, O. V. Trevisan, Braz. J. Chem. Eng. 31 (3) (2014) 571—590. https://doi.org/10.1590/0104-6632.20140313s00001853.

S.W. Hasan, M.T. Ghannam, N. Esmail, Fuel 89 (5) (2010) 1095—1100. https://doi.org/10.1016/j.fuel.2009.12.021.

B.M. Yaghi, A. Al-Bemani, Energy Sources 24 (2) (2002) 93—102. https://doi.org/10.1080/00908310252774417.

P. Gateau, I. Henaut, L. Barre, J. F. Argillier, Oil Gas Sci. Technol. 59 (5) (2004) 503—509. https://doi.org/10.2516/ogst:2004035.

M.S. Rana, V. Sa´mano, J. Ancheyta, J.A.I. Diaz, Fuel 86 (2007) 1216—1231. https://doi.org/10.1016/j.fuel.2006.08.004.

N. Shigemoto, R.S. Al-Maamari, B.Y. Jibril, A. Hirayama, Energy Fuels 20 (6) (2006) 2504—2508. https://doi.org/10.1021/ef060074h.

J.J. Wylde, D. Leinweber, D. Low, G. Botthof, A.P. Oliveira, C. Royle, C. Kayser, Proc. World Heavy Oil Congr., Aberdeen, Scottland, Canada Inc (2012).

A. Bensakhria, Y. Peysson, G. Antonini, Oil Gas Sci. Technol. 59 (5) (2004) 523—533. https://doi.org/10.2516/ogst:2004037.

T. Zhou, K.C. Leong, K.H. Yeo, Int. J. Heat Mass Transfer 49 (7-8) (2006) 1462—1471. https://doi.org/10.1016/j.ijheatmasstransfer.2005.09.023.

S.N. Milligan, R.L. Johnston, T.L. Burden, W.R. Dreher, K.W. Smith, DRAG Harris, U.S. Patent Application 8,022,118 B2 (2011). https://patentimages.storage.googleapis.com/dd/4e/8d/8725cef978517d/US8022118.pdf.

Z. Matras, T. Malcher, B. Gzyl-Malcher, Thin Solid Films 516 (24) (2008) 8848—8851. https://doi.org/10.1016/j.tsf.2007.11.057.

R.A. Soldi, A.R.S. Oliveira, R.V. Barbosa, M.A.F. Cesar-Oliveira, Eur. Polym. J. 43 (8) (2007) 3671—3678. https://doi.org/10.1016/j.eurpolymj.2006.07.021.

J. Jing, R. Yin, Y. Yuan, Y. Shi, J. Sun, M. Zhang, ACS Omega 5 (2020) 9870—9884. https://doi.org/10.1021/acsomega.0c00097.

M.T. Ghannam, N. Esmail, Pet. Sci. Technol. 24 (8) (2006) 985—999. https://doi.org/10.1081/LFT-200048166.

C. Chang, Q.D. Nguyen, H.P. Rønningsen, J. Non-Newtonian Fluid Mech. 87 (2—3) (1999) 127—154. https://doi.org/10.1016/S0377-0257(99)00059-2.

E. Worrell, C. Galitsky, Energy Efficiency Improvement in the Petroleum Refining Industry, ACEEE Summer Study on Energy Efficiency in Industry, NY, August (2005) 158—169. https://doi.org/10.2172/862119.

M. Mahinroosta, Review on Energy Efficiency Improvement methods for Oil and Gas Industries, In Proceedings of the

nd Conference on Emerging Trends in Energy Conservation, Tehran, Iran (2013). https://www.researchgate.net/publication/301221524_A_Review_on_Energy_Efficiency_Improvement_methods_for_Oil_and_Gas_Industries.

E. Yanez, A. Ramírez, A. Uribe, E. Castillo, A. Faaij, J. Cleaner Prod. 176 (2018) 604—628. https://doi.org/10.1016/j.jclepro.2017.12.085.

W. Ping, X. Changfang, X. Shiming, G. Yulin, Procedia Environ. Sci. 12 (2012) 387—393. https://doi.org/10.1016/j.proenv.2012.01.294.

F.M. White, Fluid Mechanics, 7th ed., McGraw-Hill, a business unit of The McGraw-Hill Companies, Inc. (2011). http://ftp.demec.ufpr.br/disciplinas/TM240/Marchi/Bibliografia/White_2011_7ed_Fluid-Mechanics.pdf.

W.S. Janna, Introduction to Fluid Mechanics, 4th ed. CRC Press, Taylor & Francis Group, LLC., (2010). https://doi.org/10.1201/b18979.

S. Sarbjit, Experiments in Fluid Mechanics, 2nd ed., PHI Learning Pvt. Ltd, New Delhi, (2012). ISBN: 9788120345119, 8120345118.

R.I. Ibrahim, M.K. Oudah, A.F. Hassan, J. Pet. Sci. Eng. 156 (2017) 356—365. https://doi.org/10.1016/j.petrol.2017.05.028.

L. Vafajoo, K. Ganjian, M. Fattahi, J. Pet. Sci. Eng. 90—91 (2012) 107—111. https://doi.org/10.1016/j.petrol.2012.04.022.

B.Y. Kim, J.H. Moon, T.-H. Sung, S.-M. Yang, J.-D. Kim, Sep. Sci. Technol. 37 (6) (2002) 1307—1320. https://doi.org/10.1081/SS-120002613.

A.J. Kidnay, W.R. Parrish, D. G. McCartney, Fundamentals of Natural Gas Processing, 3rd ed., CRC Press, Taylor & Francis Group, LLC. (2019). https://doi.org/10.1201/9780429464942.

Downloads

Published

Issue

Section

License

Copyright (c) 2021 Walaa Mahmoud Shehata, Mohamed Galal Helal, Fatma Khalifa Gad

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.