RESISTANCE TO FROST ACTION AND MICROBIOLOGICAL CORROSION OF NOVEL CERAMIC COMPOSITES

Scientific paper

DOI:

https://doi.org/10.2298/CICEQ210904016JKeywords:

waste treatment, fly ash, ceramic, weathering, pore size distribution, thermal analysisAbstract

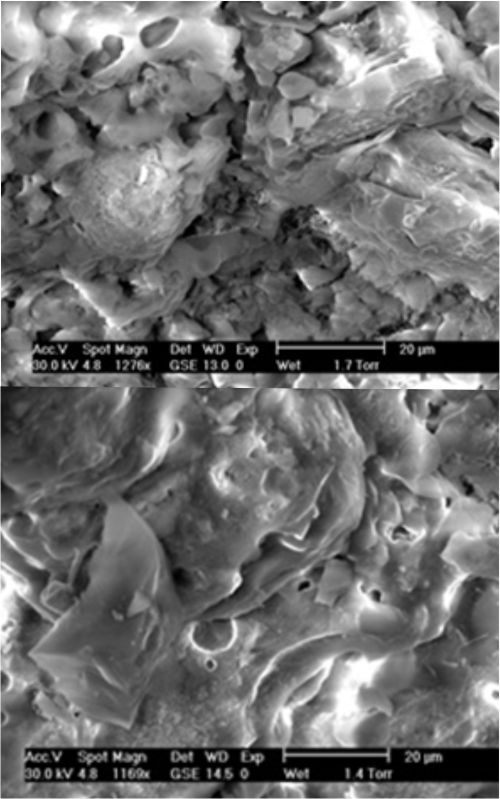

This work illustrates the prediction of frost action mechanisms on ceramic compacts and their biocorrosion resistance to fungus action. The ceramic compacts were produced from two raw materials: coal fly ash (40 wt.%) and clay material (60 wt.%). The ceramics models were made in laboratory conditions by pressing (P = 45 MPa), drying (105 °C, 3h), and sintering (1100 °C, 1 h; heating rates 3 °C/min and 10 °C/min.). The mechanisms responsible for the deterioration of the designed ceramic compacts were defined based on the values of the total porosity, pore size distribution, pore critical radius, and the Maage factor, as well as on the values of water permeability. The biocorrosion process was investigated using Aspergillus niger fungus as a model microorganism. The different degrees of fungus colonization on the designed compacts were comparatively analyzed based on the Scanning Electron Microscopy investigation results. The gained results are encouraging as they show that the utilization of fly ash (40 wt.%) in ceramic composites is possible without significant deterioration of their durability (frost action and microbiological corrosion resistance) compared with the ones whose production was based only on clay material.

References

B. Angjusheva, E. Fidancevska, K. Lisichkov, V. Jovanov, J. Eng. Process. Manage. 8 (2016) 73—79. https://doi.org/10.7251/JEPMEN1608073A.

S. Kramar, L. Zilbert, E. Fidancevska, V. Jovanov, B. Angjusheva, V. Ducman, Mater. Constr. 69 (333) (2019) e176. https://doi.org/10.3989/mc.2019.11617.

D. Jubinville, E. Esmizadeh, S. Saikrishnan, C. Tzoganakis, T. Mekonnen, Sustainable Mater. Technol. 25 (2020) e00188. https://doi.org/10.1016/j.susmat.2020.e00188.

B. Angjusheva, E. Fidancevska, V. Jovanov, Qual. Life 7(3—4) (2016) 59—65. https://doi.org/10.7251/QOL1603059A.

B. Angjusheva, E. Fidancevska, V. Jovanov, Qual. Life 7(3—4) (2016) 53—58. https://doi.org/10.7251/QOL1603053A.

M. Sutcu, E. Erdogmus, O. Gencel, A. A Gholapour, E. Atan, T. Ozbakkaloglu, J. Cleaner Prod. 233 (2019) 753—764. https://doi.org/10.1016/j.jclepro.2019.06.017.

P. Lopez-Arcea, J. Garcia-Guinea, Build. Environ. 40 (2005) 929—941. https://doi.org/10.1016/j.buildenv.2004.08.027.

P. Berdahl, H. Akbari, R. Levinson, W.A. Miller, Constr. Build. Mater. 22 (2008) 423—433. https://doi.org/10.1016/j.conbuildmat.2006.10.015.

K. Ikeda, H.-S. Kim, K. Kaizu, A. Higashi, J. Eur. Ceram. Soc. 24 (2004) 3671—3677. https://doi.org/10.1016/j.jeurceramsoc.2003.12.014.

M. Maage, ZI, Ziegelind. Int. 9 (1990) 472—481.

M. Maage, ZI, Ziegelind. Int. 10 (1990) 582—588.

L. Franke, H. Bentrup, ZI, Ziegelind. Int. 7-8 (1993) 483—492.

R. Koroth, P. Fazio, D. Fedman, J. Archit. Eng. 9 (1998) 87—93. https://ascelibrary.org/doi/10.1061/%28ASCE%291076-0431%281998%294%3A1%2826%29.

G.C. Robinson, Amer. Ceram. Soc. Bull. 56 (1995) 1071—1075.

P. Vincenzini, Ceramurgia 3 (1974) 176—188.

I.N. Grubeša, M. Vračević , J. Ranogajec, S. Vučetić, Materials 13 (2020) 2364. https://doi.org/10.3390/ma13102364.

J.G. Ranogajec, S.L. Markov, O.Lj. Rudić, S.B. Vuĉetić, V.S. Ducman, Acta Period. Technol. 42 (1-288) (2011) 197—207. https://doi.org/10.2298/APT1142197R.

M.L. Coutinho, J.P. Veig, M.F. Macedo, A.Z. Miller, Coatings 10 (2020) 1169. https://doi.org/10.3390/coatings10121169.

W. Sand, Int. Biodeterior. 40 (1997) 183—190. https://doi.org/10.1016/S0964-8305(97)00048-6.

J. Ranogajec, M. Radeka, in Self-Cleaning Materials and Surfaces, W.A. Daoud Ed., Wiley Online Library, (2013) 89—128. https://doi.org/10.1002/9781118652336.ch4.

V. Jovanov, B. Anguseva, K. Pantovic, E. Fidancevska, “Ecological Truth” ECO-IST’15, XXIII International conference, Kopaonik, Serbia (2015) 207—211.

V. Ducman, A.S. Skapin, M. Radeka, J. Ranogajec, Ceram. Int. 37 (2011) 85—91. https://doi.org/10.1016/j.ceramint.2010.08.012.

M. Radeka, J. Ranogajec, J. Kiurski, S. Markov, R. Marinković-Nedučin, J. Eur. Ceram. Soc. 27 (2—3) (2007) 1763—1766. https://doi.org/10.1016/j.jeurceramsoc.2006.05.001.

T. Chand Dakal, S.S. Cameotra, Environ. Sci. Eur. 24 (2012) 1—13. https://doi.org/10.1186/2190-4715-24-36.

B. Angjusheva, E. Fidancevska,V. Jovanov, Chem. Ind. Chem. Eng. Q. 18 (2012) 245—254. https://doi.org/10.2298/CICEQ110607001A.

H.S. Kim, J.M. Kim. K. Ikeda, Br. Ceram. Trans. 102 (2003)133-137. https://doi.org/10.1179/096797803225001623.

M. Sveda, ZI, Ziegelind. Int. 55, (2002) 29—33.

M. Sveda, ZI, Ziegelind. Int. 57 (2004) 36—43.

T. Hulan, I. Stubna, J. Ondruska, A. Trnik, Minerals 10(10) (2020) 930. https://doi.org/10.3390/min10100930.

Downloads

Published

Issue

Section

License

Copyright (c) 2021 Vojo Jovanov, Snežana Vučetić, Siniša Markov, Biljana Angjusheva, Emilija Fidancevska, Jonjaua Ranogajec

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.