ARTIFICIAL NEURAL NETWORK MODELING FOR DRYING KINETICS OF PADDY USING A CABINET TRAY DRYER

Scientific paper

DOI:

https://doi.org/10.2298/CICEQ220106017SKeywords:

Cabinet tray dryer, Equilibrium moisture content, Mathematical modeling, ANN modeling, Effective diffusivity, Activation energyAbstract

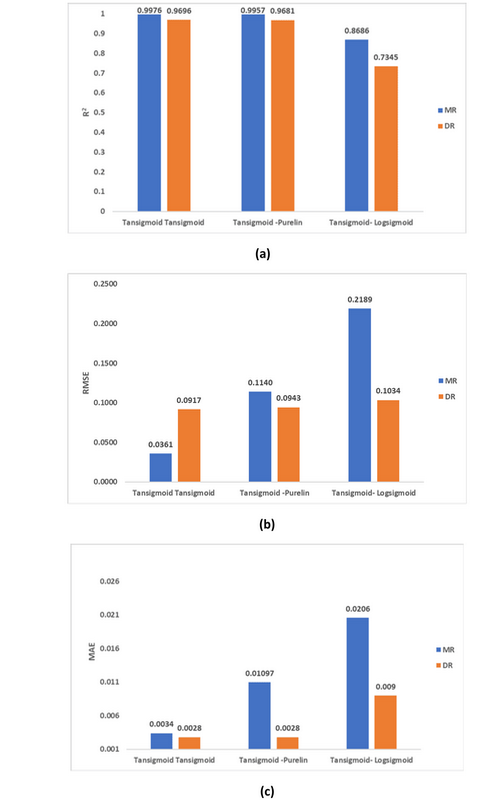

The study of drying kinetics and characteristics of agricultural products is essential for drying time estimation, designing dryers, and optimizing the drying process. Moisture diffusivity under different drying conditions is crucial to process and equipment design. The drying kinetics of paddy using a cabinet tray dryer was modeled using an Artificial Neural Network (ANN) technique. For predicting moisture ratio and drying rate, the Levenberg-Marquardt (LM) training algorithm with TANSIGMOID and TANSIGMOID hidden layer activation function provided superior results. A comparative evaluation of the predicting abilities of ANN and 12 different mathematical drying models was also carried out. The Midilli model was adequate for fitting the experimental data with an R2 comparable to that of the ANN. However, the RMSE observed for ANN (0.0360) was significantly lower than that of the Midilli model (0.1673 to 0.712). Effective moisture diffusivity increased with an increase in temperature from 15.05 10-9 m2/s to 28.5 10-9 m2/s. The activation energy for drying paddy grains varied between 6.8 kJ/mol to 7.3 kJ/mol, which showed a moderate energy requirement for moisture diffusion.

References

M.R. Manikantan, P. Barnwal, R.K. Goyal, J. Food Sci. Technol. 51 (2014) 813—819. https://doi.org/10.1007/s13197-013-1250-1.

S. Rajasekar, N. Meyyappan, D.G. Rao, ChemBioEng Rev. 4 (2017) 304—309. https://doi.org/10.1002/cben.201600018.

O. Yaldýz, C. Ertekýn, Drying Technol. 19 (2001) 583—597. https://doi.org/10.1081/DRT-100103936.

N. Norhadi, A.M. Akhir, N.R. Rosli, F. Mulana, Malaysian J. Chem.Eng. Technol. 3 (2020) 51—59. https://doi.org/10.24191/mjcet.v3i2.10965.

R. Winiczenko, K. Górnicki, A. Kaleta, M. Janaszek-Mańkowska, Neural Comput. Appl. 30 (2018) 1795—1809. https://doi.org/10.1007/s00521-016-2801-y.

V.K. Chasiotis, D.A. Tzempelikos, A.E. Filios, K.P. Moustris, Comput. Electron. Agric. 172 (2020). https://doi.org/10.1016/j.compag.2019.105074.

M. Golmohammadi, M. Foroughi-dahr, M. R. Hamaneh, A. Reza, S. Jalaledin, Iran. J. Chem. Chem. Eng. 35 (2016) 105—117. https://doi.org/10.30492/IJCCE.2016.22064.

S. Chakraborty, M. Sarma, J. Bora, S. Faisal, M.K. Hazarika, Agric. Eng. Int. 18 (2016) 177—189. https://cigrjournal.org/index.php/Ejounral/article/view/3645/2477.

A.D. Arjun, S. Ganapathy, T. Pandiarajan, K. Bhuvaneswari, M. Duraisamy, Int. J. Agric. Eng. 10 (2017) 623—630. https://doi.org/10.15740/HAS/IJAE/10.2/623-630.

M. Beigi, M. Torki-Harchegani, M. Mahmoodi-Eshkaftaki, Chem. Ind. Chem. Eng. Q. 23 (2017) 251—258. https://doi.org/10.2298/CICEQ160524039B.

J. Zhang, P. Ma, X. Zhang, B. Wang, J. Wu, X. Xing, J. Therm. Anal. Calorim. 134 (2018) 2359—2365. https://doi.org/10.1007/s10973-018-7716-7.

B. Pattanayak, S.S. Mohapatra, H.C. Das, Int. J. Postharvest Technol. Innov 6 (2019) 162—178. https://doi.org/10.1504/IJPTI.2019.106194.

E. Taghinezhad, A. Szumny, M. Kaveh, V.R. Sharabiani, A. Kumar, N. Shimizu, Foods 9 (2020) 1—17.

https://doi.org/10.3390/foods9010086.

A. Sitorus, Novrinaldi, S.A. Putra, I.S. Cebro, R. Bulan, Case Stud. Therm. Eng. 28 (2021) 1—9. https://doi.org/10.1016/j.csite.2021.101572.

S. Chakraborty, S.P. Gautam, M. Sarma, M.K. Hazarika, Food Sci. Technol. Int. 27 (2021) 746—763. https://doi.org/10.1177/1082013220983953.

M. Lutovska, V. Mitrevski, I. Pavkov, M. Babic, V. Mijakovski, T. Geramitcioski, Z. Stamenkovic, J. Process. Energy Agric. 21 (2017) 91—96. https://scindeks.ceon.rs/article.aspx?artid=1821-44871702091L.

D.G. Rao, B.S. Sridhar, G. Nanjundaiah, J. Food Eng. 17 (1992) 49—58. https://doi.org/10.1016/0260-8774(92)90064-D.

M. Ahmet Tütüncü, T.P. Labuza, J. Food Eng. 30 (1996) 433—447. https://doi.org/10.1016/S0260-8774(96)00028-3.

T. Gunhan, V. Demir, E. Hancioglu, A. Hepbasli, Energy Convers. Manage. 46 (2005) 1667—1679. https://doi.org/doi:10.1016/j.enconman.2004.10.001.

R.L. Sawhney, P.N. Sarsavadia, D.R. Pangavhane, S.P. Singh, Drying Technol. 17 (1999) 299—315. https://doi.org/10.1080/07373939908917531.

A. Tarafdar, N. Jothi, B.P. Kaur, J. Appl. Res. Med. Aromat. Plants 24 (2021) 1—8. https://doi.org/10.1016/j.jarmap.2021.100306.

G.O. Ondier, T.J. Siebenmorgen, R.C. Bautista, A. Mauromoustakos, Trans. ASABE. 50 (2011) 1007—1013. https://doi.org/10.13031/2013.37085.

J.O. Ojediran, A.O. Raji, Int. Food Res. J. 17 (2010) 1095—1106. http://www.ifrj.upm.edu.my/17%20(04)%202010/(30)%20IFRJ-2010-042%20Raji%20Nigeria[1].pdf.

V.C. Siqueira, R.A. Leite, G.A. Mabasso, E.A.S. Martins, W.D. Quequeto, E.P. Isquierdo, Cienc. Agrotecnol. 44 (2020) 1—10. https://doi.org/10.1590/1413-7054202044011320.

S. Rafiee, A. Keyhani, A. Jafari, Int. J. Food Prop. 11 (2008) 223—232. https://doi.org/10.1080/10942910701291858.

B.H. Hassan, A.I. Hobani, J. Food Process Eng. 23 (2000) 177—189. https://doi.org/10.1111/j.1745-4530.2000.tb00510.x.

I.L. Pardeshi, S. Arora, P.A. Borker, Drying Technol. 27 (2009) 288—295. https://doi.org/10.1080/07373930802606451.

N.A. Akgun, I. Doymaz, J. Food Eng. 68 (2005) 455—461. https://doi.org/10.1016/j.jfoodeng.2004.06.023.

Xiao-Kang Yi, Wen-Fu Wu, Ya-Qiu Zhang, Jun-Xing Li, Hua-Ping Luo, Math. Probl. Eng. (2012) 1—19. https://doi.org/10.1155/2012/386214.

Y.G. Keneni, A.K. (Trine) Hvoslef-Eide, J.M. Marchetti , Ind. Crops Prod. 132 (2019) 12—20. https://doi.org/10.1016/j.indcrop.2019.02.012.

Qing-An Zhang, Yun Song, Xi Wang, Wu-Qi Zhao, Xue-Hui Fan, CYTA J. Food 14 (2016) 509—517. https://doi.org/10.1080/19476337.2015.1136843.

S. Soodmand-Moghaddam, M. Sharifi, H. Zareiforoush, H. Mobli, Qual. Assur. Saf. Crop.12 (2020) 57—66. https://doi.org/10.15586/QAS2019.658.

P. Thant, P. Robi, P. Mahanta, Int. J. Eng. Appl. Sci. 5 (2018) 118—123. https://www.ijeas.org/download_data/IJEAS0503034.pdf.

A. Sitorus, Novrinaldi, S.A. Putra, I.S. Cebro, R. Bulan, Case Stud. Therm. Eng. 28 (2021). https://doi.org/10.1016/j.csite.2021.101572.

S. Kono, I. Kawamura, T. Araki, Y. Sagara, Int. J. Refrig. 65 (2016) 218—227. https://doi.org/10.1016/j.ijrefrig.2015.10.009.

B. Osodo, D. Nyaanga, J. Kiplagat, J. Muguthu, Am. J. Food Technol. 6 (2018) 263—271. http://pubs.sciepub.com/ajfst/6/6/6/.

M. Kashiri, A.D. Garmakhany, A.A. Dehghani, Qual. Assur. Saf. Crop. Foods 4 (2012) 179—184. https://doi.org/10.1111/j.1757-837X.2012.00184.x.

I. Golpour, R. Amiri Chayjan, J. Amiri Parian, J. Khazaei, J. Agric. Sci. Technol. 17 (2015) 287—298. https://jast.modares.ac.ir/article-23-10165-en.pdf.

U. Şahin, H.K. Öztürk, J. Food Process Eng. 41 (2018) 1—14. https://doi.org/10.1111/jfpe.12804.

J.W. Bai, H.W. Xiao, H. L. Ma, C.S. Zhou, J. Food Qual. (2018) 1—9. https://doi.org/10.1155/2018/3278595.

M. Garg, S. Sharma, S. Varmani, S. Sadhu, Int. J. Food Sci. Nutr. 3 (2014) 61—66. https://www.researchgate.net/publication/341440997_DRYING_KINETICS_OF_THIN_LAYER_PEA_PODS_USING_TRAY_DRYING#fullTextFileContent.

A. Motevali, S. Younji, R.A. Chayjan, N. Aghilinategh, A. Banakar, Int. Agrophys. 27 (2013) 39—47. https://doi.org/10.2478/v10247-012-0066-y.

A. Fernandez, C. Román, G. Mazza, R. Rodriguez, Case Stud. Therm. Eng. 12(2018) 248—257. https://doi.org/10.1016/j.csite.2018.04.015.

Downloads

Published

Issue

Section

License

Copyright (c) 2021 Rajasekar Subramanyam, Meyyappan Narayanan

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.