IMPROVEMENT OF THE MONOCHLOROBENZENE SEPARATION PROCESS THROUGH HEAT INTEGRATION: A SUSTAINABILITY-BASED ASSESSMENT

Scientific paper

DOI:

https://doi.org/10.2298/CICEQ220311011PKeywords:

Eco-efficiency, Heat integration, Monochlorobenzene, Process simulation, Sustainability indicators, Utility PlantsAbstract

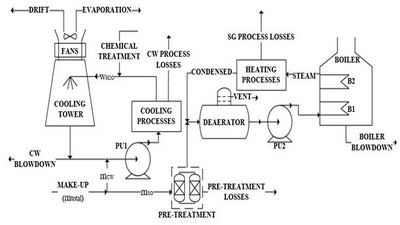

Chlorobenzene is an important chemical intermediate in the production of commodities, such as herbicides, dyestuffs, and rubber. In this work, a heat integration was proposed for a monochlorobenzene separation process. The conventional process structure and the proposed integrated one were designed and simulated. An optimization focused on minimizing the cooling and heating costs was performed to obtain the best-operating conditions for the heat integration. The simulation of a utility plant, including cooling water and steam generation sections, was also carried out for more accurate estimations of CO2 emissions, water, energy consumption, and operating costs. The processes were evaluated and compared in terms of their sustainable performances using the eco-efficiency comparison index method and environmental and economic indicators, such as CO2 emission, water consumption, and utility cost, to assess the benefits of heat integration. The results demonstrated that the proposed strategy reduced around 57% of all environmental impacts and utility costs. As the composite evaluation index from the performance indicators showed, the proposed optimal heat integrated industrial plant significantly improved the initial processes’ eco-efficiencies, up to 83%, proving a suitable strategy for a more sustainable process.

References

United Nations. Transforming Our World: the 2030 Agenda for Sustainable Development (2015), sdgs.un.org/2030agenda [accessed 14 March 2022].

A.J. Tula, M. Eden, R. Gani, AIChE J. 66 (2019) 16819. https://doi.org/10.1002/aic.16819

R.O. Santos, L.S. Santos, D.M. Prata, J. Cleaner Prod. 186 (2018) 821—830. https://doi.org/10.1016/j.jclepro.2018.03.108

P.V. Mangili, D.M. Prata, Chem. Eng. Process. 135 (2019) 93—107. https://doi.org/10.1016/j.cep.2018.11.020

P.C. Gonçalves, L.P.C. Monteiro, L.S. Santos, J. Cleaner Prod. 270 (2020) 122322. https://doi.org/10.1016/j.jclepro.2020.122322

P.G. Junqueira, P.V. Mangili, R.O. Santos, L.S. Santos, D.M. Prata, Chem. Eng. Process. 130 (2018) 309—325. https://doi.org/10.1016/j.cep.2018.06.010

P.G. Junqueira, I.N. Caxiano, P.V. Mangili, D.M. Prata, Comput. Chem. Eng. 136 (2020) 106783. https://doi.org/10.1016/j.compchemeng.2020.106783

P.V. Mangili, D.M. Prata, Chem. Eng. Sci. 212 (2020) 115313. https://doi.org/10.1016/j.ces.2019.115313

I.N. Caxiano, P.G. Junqueira, P.V. Mangili, D.M. Prata, Chem. Eng. Process. 147 (2020) 107784. https://doi.org/10.1016/j.cep.2019.107784

H.N.C. da Silva, D.M. Prata, L.P. Zotes, L.V. Mattos, J. Cleaner. Prod. 200 (2018) 598—608. https://doi.org/10.1016/j.jclepro.2018.07.120

D.M. Prata, E.L. Lima, J.C. Pinto, Macromol. Symp. 271 (2008) 26—37. https://doi.org/10.1002/masy.200851104

S. Sitter, Q. Chen, I.E. Grossmann, Curr. Opin. Chem. Eng. 25 (2019) 87—94. https://doi.org/10.1016/j.coche.2018.12.006

P.V. Mangili, L.S. Santos, D.M. Prata, Comput. Chem. Eng. 130 (2019) 106558. https://doi.org/10.1016/j.compchemeng.2019.106558

S.D. Pravasi, in Encyclopedia of Toxicology, P. Wexler Ed., Elsevier, Amsterdam (2014), p. 870—873. eBook ISBN: 9780123864550

C. Güler, in GIS and Geostatistical Techniques for Groundwater Science, Elsevier, Amsterdam (2019), p. 251—268. eBook ISBN: 9780128154144

C.B. Silva, S. Mitri, T. Pavesi, E. Saggioro, J.C. Moreira, Cad. Saúde Colet. 22 (2014) 329—342. https://doi.org/10.1590/1414-462X201400040006

W.D. Seider, D.R. Lewin, J.D. Seader, S. Widagdo, R. Gani, K. Ming Ng, Product and Process Design Principles: Synthesis, Analysis and Evaluation, John Wiley & Sons, West Sussex (2016), p. 784. ISBN: 978-1-119-28263-1

R. Turton, R. Bailie, W.B. Whitting, J.A. Shaeiwitz, D. Bhattacharyya, Analysis, Synthesis and Design of Chemical Processes, Prentice Hall, Upper Saddle River (2018), p. 243. ISBN: 978-0-13-261812-0

P.Y. Liew, S.R.W. Alwi, J.S. Lim, P.S. Varbanov, J.J. Klemes, Z.A. Manan, J. Cleaner. Prod. 77 (2014) 94—104. https://doi.org/10.1016/j.jclepro.2013.12.047

C.P. Pereira, D.M. Prata, L.S. Santos, L.P.C. Monteiro, Braz. J. Chem. Eng. 35 (2018) 63—84.

https://doi.org/10.1590/0104-6632.20180351s20160370

Intergovernmental Panel on Climate Change, 2006 IPCC Guidelines for National Greenhouse Gas Inventories, www.ipcc-nggip.iges.or.jp/public/2006gl/ [accessed 3 August 2021].

Ministério da Ciência, Tecnologia, Inovações e Comunicações, Fator Médio – Inventários Corporativos, www.gov.br/mcti/pt-br/acompanhe-o-mcti/sirene/dados-e-ferramentas/fatores-de-emissao [accessed 1 August 2021].

U.S. Energy Information Administration, Henry Hub Natural Gas Spot Price, https://www.eia.gov/dnav/ng/hist/rngwhhdA.htm. [accessed 25 November 2021].

J.R. Couper, W.R. Penney, J.R. Fair, S.M. Walas, Chemical Process Equipment: Selection and Design, Butterworth-Heinemann, Oxford (2012), p. 223. ISBN: 978-0-12-396959-0.

Downloads

Published

Issue

Section

License

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.