Enhanced lipid extraction from microalgae in biodiesel production

Main Article Content

Abstract

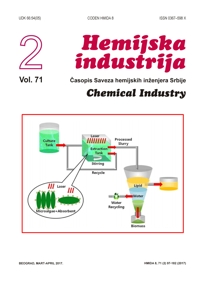

In order to secure more effective lipid extraction method, this research investigated new lipid extraction method using laser with absorbent and sought its optimum operation control. In addition, this study compared lipid extraction efficiency and FAME conversion rate between laser extraction method at optimum condition and existing extraction method. Results from experiments for optimizing lipid extraction method using laser showed that the maximum extraction efficiency (81.8%) was attained when using laser with an output capacity of 75Wh/L. Extraction efficiency increased up to 90.8% when microwave treatment as pretreatment process was conducted. Addition of absorbents during lipid extraction process with laser showed higher extraction efficiency than laser and chemical method. It was also found that laser extraction method with absorbent had higher total fatty acid content (853.7 mg/g oil) in extracted lipid than chemical extraction method (825.4 mg/g oil). Furthermore, it had the highest FAME conversion rate (94.2%).

Downloads

Article Details

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

References

H. E. Hoydonckx, D. E. De Vos, S. A. Chavan, P.A. Jacobs, Esterification and transesterification of renewable chemicals, Top. Catal. 27 (2004) 83–96.

Y. Chisti, Biodiesel from microalgae, Biotechnol. Adv. 25 (2007) 294–306.

T.P. Durrett, C. Benning, J. Ohlrogge, Plant triacylglycerols as feedstock for the production of biofuels, Plant J. 54 (2008) 593–607.

S. Amin, Review on biofuel oil and gas production processes from micro algae, Energ. Convers. Manage. 50 (2009) 1834–1840.

J.Y. Lee, C. Yoo, S.Y. Jun, C.Y. Ahn, H.M. Oh, Comparison of several methods for effective lipid extraction from microalgae, Bioresour. Technol. 101 (2007) S75–S77.

Y. Jung, Comparative analysis of lipid extraction from energy microalgae, Scenedesmus obliquus, Masters Theses, Kyungpook National University, Daegu, 2012 (In Korean).

Q. Hu, M. Sommerfeld, E. Jarvis, M. Ghirardi, M. Posewitz, M. Seibert, A. Darzins, Microalgal triacylglycerols as feedstocks for biofuel production: perspectives and advances, Plant J. 54 (2008) 621–639.

P.Y. Choi, Lipid extraction and and pretreatment esterification from microalgae, Masters Theses, Korea University, Seoul, 2012 (In Korean).

C.L. Tautorus, Low possible causes for decreased stability of canola oil processed from green seed, J. Am. Oil Chem. Soc. 71 (1994) 1123–1128.

T. Issariyakul, A.K. Dalai, Biodiesel production from greenseed canola oil, Energy Fuels 24 (2010) 4652–4658.

M.J. Griffiths, S.T.L. Harrison, Lipid productivity as a key characteristic for choosing algal species for biodiesel production, J. Appl. Phycol. 21 (2009) 493–507.

E.G. Bligh, W.J. Dyer, A rapid method for total lipid extraction and purification, Can. J. Biochem. Physiol. 37 (1959) 911–917.

P. Prabakaran, A.D. Ravindran, A comparative study on effective cell disruption methods for lipid extraction from microalgae, Lett. Appl. Microbiol. 53 (2011) 150–154.

Y.H. Seo, M. Sung, Y.K. Oh, J.I. Han, Lipid extracvtion and esterification for microalgae-based biodiesel production using pyrite (FeS2), Bioresour. Technol. 191 (2015) 420–425.

A. Ranjan, V.S. Moholkar, Mechanistic assessment of microalgal lipid extraction, Ind. Eng. Chem. Res. 49 (2010) 2979–2985.

American Oil Chemists Society, AOCS Officical Method cd 3d-63: Acid Value. Official Method and Recommended practices of the AOCS, AOCS, Champaign, IL, 2009.

N.Y. Kim, Extraction, purification and optimization of the lipid for biodiesel from Scenedesmus sp., Masters Thesis, Kangwon National University, Kangwon, 2010 (In Korean).

J.Y. Lee, Comparison of several methods for effective lipid extraction from microalgae, Bioresour. Technol. 101 (2010) S75–S77.